All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(8 products available)

The Menards cement mixer is an essential tool used to mix cement, concrete, and other materials uniformly. There are different types of cement mixers available:

Proper maintenance and specifications are important for the menards concrete mixers to perform the mixing function of construction materials like cement, water, and aggregate in the required ratio efficiently.

The common specifications along with their corresponding maintenance requirements are as follows.

Capacity and wattage

On average, 2-3 mixers are used per treatment panel. Each mixer can take up to 30 - 40L of liquid. A 240L mixer will create 1 - 1.5 panels of liquid sunshine per mix. The total wattage varies based on the size and function of the cement mixer. A typical 3.5 cu ft mixer has a power rating of 250-350 watts. Higher wattage in mixers indicates a faster motor speed and mixing capability.

Maintenance

- Check water hoses and connectors for leaks before starting the mixer. Fix any leaks identified.

- Use a heat gun or manual to troubleshoot any mixer faults.

- Clean the mixer drum daily before it dries to avoid concrete build-up.

- Apply fuel or engine oil to the mixer drum and its exterior daily.

- Remove the drum cover and clean interior parts with a high-pressure washer.

- Remove grout and tar build-up with a wire brush. Make sure other parts are bristle-free.

- Clean the cement mixer spare parts with engine oil, diesel, or grout remover.

- Clean off excess oil with a microfiber towel.

Power source

The power source for menards cement mixers can be gas or electric. In gas-powered mixers, the engine has to be pulled from its receptacle to start the process, while in electric mixers, an electric outlet has to be connected. The gas-powered mixer is more mobile but requires more physical work to start, while the electric mixer is more hands-off and works better for smaller volumes of work.

Drum style

This refers to how the drum rotates to mix the cement and concrete. In front-tipping drums, the mixed material comes out from the front side of the mixer when the drum is tilted forward. In reverse-tipping drums, the mixed materials come out from the back side of the mixer, i.e., the drum has to reverse to make the mixed content come out. The reverse rotation also ensures that the mixing process happens when the drum is moving in any direction.

Cement mixers can be used in various scenarios, such as at home, on construction sites, in public infrastructure construction, and for other private and commercial uses.

Home DIY projects and small-scale concrete mixing

Concrete mixers are extremely useful for home improvement DIY projects, especially portable mixers. House owners can use the mixers to mix concrete for repairs, small construction projects, landscaping features, or the building of garden structures like patios and benches.

Construction sites

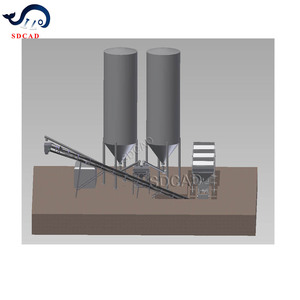

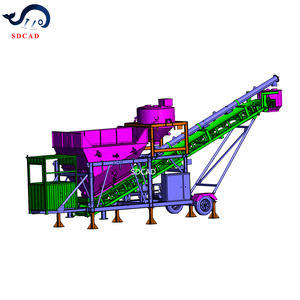

Cement mixers are the backbone of construction sites. Mixers are used to produce the binding material needed for construction. Apart from mixing concrete, many mixers also mix other materials required for construction. When using mixers for construction, it is pertinent to choose the right size for the job. Mobile mixers are great options for use on large construction sites where the supply of ready-made concrete is not an option.

Cement mixers have also been adapted for use in other types of construction like tunnels where portable, high-capacity concrete mixers with feeding hoppers and belt conveyors are used. Tunnel construction often also involves the use of high-strength concrete that is designed for specific applications.

Infrastructure projects

Cement mixers are the go-to machines for all kinds of infrastructure-building projects, be it roads, bridges, dams, or other public infrastructure. Concrete produced with cement mixers is favored for its durability and strength, which ensure structural integrity.

Industrial applications

Concrete cement mixers are used in different production industries for the mass production of cement-based products like precast concrete elements, concrete blocks, and mo9re.

Rental services

Cement mixers are also available for rental services. This is especially so for expensive and large-scale mixers, which customers will not want to spend money on when they would only be used a few times or for small-scale projects.

Business buyers should consider these critical factors of Menards cement mixers when choosing for their purpose:

Determine the type of mixer needed for the worksite

Is the work stationary or portable? A concrete mixer bucket is suitable for a portable mixer since it can mix concrete while driving. An ideal portable concrete mixer for housing construction is the tilting drum mixer; it's easy to use and lightweight. For portable mixing with a cement truck, Menards mixer trucks are preferable. Use a stationary mixer like the planetary mixer for large mixed concrete quantities.

Know how to power the mixer

A gasoline-powered cement mixer is practical for outdoor use, while electric works fine for indoor purposes.

Assess how much mixing capacity is needed

The mixing known is measured in cubic feet and determines how much concrete the mixer can make in one batch. Smaller mixers range from 3 to 5 cubic feet, and larger mixers range from 8 to 12 cubic feet.

Find out how to load and unload the mixed concrete

Cement mixers with a loading shovel and unloading chutes are preferable to those that require manual shovel loading and unloading. The shovel and chutes make the process easier, faster, and more efficient.

Consider the mixing method

Menards mixers can either be mixed or reversed. The mixed concrete is then extracted through a discharge chute. Some models have a control panel to regulate the mix and discharge the mixed materials, while others are manually operated with a pull start.

Assess safety features

Safety features in Menards large capacity cement mixers include a roll-over protective structure, emergency-stop buttons, guardrails, and safety interlocks. Consider the safety features, especially when transporting to a construction site.

Q1: What is the difference between a concrete mixer and a cement mixer?

A1: Generally, people use both terms interchangeably. However, there is a slight distinction. A concrete mixer mixer mixes materials to make concrete. On the other hand, a cement mixer combines cement and water to create a homogenous mixture.

Q2: Does the cement mixer price affect the product's quality?

A2: Yes, sometimes the price can reflect the product's quality. However, buyers should know that a high price doesn't always guarantee better quality. It's essential to look at the features closely and consider how suitable the equipment is for the intended applications.

Q3: Can an automatic cement mixer be converted to manually mix cement?

A3: While it's theoretically possible to attempt such a conversion, manufacturers do not recommend it. Automatic mixers are designed for specific functions, and altering them could present safety risks and compromise performance.

Q4: Are there versatile mixers that can handle different types of materials besides cement?

A4: Yes, some mixing machines are designed to cope with various materials, including cement, sand, coal, flour, and graphite. Nevertheless, the mixers are not recommended for processing viscous materials. Sand, coal, and graphite are light particles; thus, they can be handled by any of the mixers mentioned. For viscous materials, like molasses, sugar syrup, or treacle, one should always use a specifically designed cement mix machine for such products.