Types of meat mincer spare parts

Apart from the above-mentioned parts of meat grinders that every supplier should know about, there are a few more that are equally important. Here is a list of spare parts along with a description:

- Wooden pusher/plastic pusher: When grinding or mincing meat, this tool is used to push the meat down into the feed tube. It acts as a buffer between the operator's hand and the meat auger blade. This allows the meat grinder to work efficiently while keeping hands safe and preventing any injuries.

- Hoppers: The big bowl on top of the meat grinder is called the hopper. Meat and other food items are placed here, where it is sliced or ground by a rotating screw known as the auger before leaving through a hole at the bottom. Hoppers come in different sizes depending on whether the meat grinder is for home use or commercial use. It is easy to clean because of its removable feature.

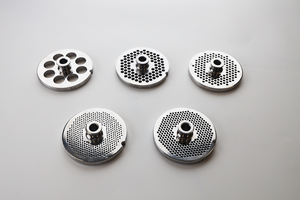

- Meat grinder plate: This plate is also called a meat grinder cutting plate. It works together with the knives to cut, chop, or grind meat into the desired texture. The plate has several sized holes, which allows the meat to pass through; the size of the holes generally determines the coarseness or smoothness of the minced meat.

- Meat grinder blade: This part is sometimes called the meat grinder knife. It comes in different shapes and sizes, depending on the thickness and type of meat to be ground. The blades are sharp and cut through the meat, making it easy for the grinder plates to do the final grinding.

- Safety guard: This important part helps prevent accidental injuries by ensuring safe operation. Guards help keep hands and other body parts away from dangerous moving parts while also keeping the working parts of the grinder shielded from outside objects. Safety guards come in many forms, such as covers, fences, and fixed shields.

Functions and features of meat mincer spare parts

Every part of the meat grinder has its own special features and functions. Understanding them helps users to maintain the machine properly and get the best results when using it.

- Auger: The main job of the auger is to push pieces of meat through the grinding plate. It is also known as a worm, screw, or conveyor. The long screw shape of the auger helps to move the meat steadily so that it is all chopped up evenly. How long or wide the auger is can change how the grinder works. An auger that is longer will push the meat further, while a wider one will be able to take bigger chunks of meat. The auger rotates in a circle, pulling the meat inside and pushing it out to be ground.

- Grinding plates: Grinding plates are metal discs with sharp knife-like holes that cut meat into little pieces. The holes allow operators to choose the size of the minced meat. The plates' strength, size, and sharp holes ensure longevity and quality.

- Knives: The knives and grinding plates work hand in hand to cut and chop meat. The grinding plate holes and the beveled-edge knives work together to grind meat. Using sharp knives is very important because they cut the meat well, making sure that the pieces are all the same size. This gives the minced meat a smooth and even quality. Knives can be replaced when they become dull.

- Stuffer tubes: The stuffer tube pushes raw meat into the sausage, made to look like rings, so the meat can be packed tightly inside and turned into linked sausages. It makes a space in the tube where the meat can go, and then it deposits the meat mixture in the tube. Stuff stuffer tubes come in different sizes: small, medium, and large, depending on the size of the sausage.

- Meat pusher: The meat pusher helps push meat down into the grinder safely and evenly. Using it prevents fingers from getting too close to the sharp blades. It also stops the meat from getting stuck inside the grinder. A high-quality meat pusher fits well with other parts of the grinder and is easy to hold and move.

Applications of Meat Mincer Spare Parts

Meat mincer spare parts have multiple applications in various industries. The following are some of the industries where they are used:

- Meat processing: Spare parts are essential for the efficient running of meat processing plants. They handle large amounts of meat and grind them into smaller, more manageable pieces during preparation.

- Catering industry: Restaurants and catering services use meat grinders in large quantities to prepare meals. Spare parts are a solution to keep these grinders working well to meet the client's needs.

- Food production: Other food production companies that need grinding machines, such as nut butter and food puree manufacturers, use meat grinders. They may need spare parts to replace worn-out components and ensure their processes run smoothly.

- Small businesses: Artisan food producers or small-scale meat processors may use grinders for their production needs. These producers can use spare parts as an affordable way to maintain or repair their grinding equipment instead of buying new machines.

- Home cooking: Home cooks or chefs who use powered or manual grinders may need spare parts to optimize the efficiency of their equipment.

- Manufacturing: Manufacturers of meat grinders and other grinding equipment often stock spare parts to provide repairs and maintenance services to their customers.

- Butchery: Butcher shops use meat grinders as an essential tool in their daily operations. They may use spare parts to repair or maintain their grinding machines.

- Training institutions: Culinary schools and training centers may use meat grinders in their cooking lessons. This equipment may require spare parts for repairs or maintenance during training.

- Construction: Meat grinders are used in construction to grind waste into smaller pieces. They need spare parts to maintain their grinding machines.

- Composting: Composting facilities use some types of grinders to mince organic matter. Composting plants may need spare parts to keep their composting machines in good working condition.

How to Choose Meat Mincer Spare Parts

-

Compatibility:

When selecting parts for a meat mincer, it is essential to pick those which are the compatible with the machine in use. While some parts may be universal and fit onto different brands and models, many are specifically designed to work only with certain meat grinder manufacturers. To determine compatibility, users should start by referencing the product manual that came with their electric or manual mincer. The manual will typically list the compatible replacement parts and accessories tailored for that particular model number and brand. If the manual is unavailable, as a next step, examine the actual meat grinder machine. Check for any model numbers or brand names printed on the body of the grinder or near any of the parts. This information can help identify compatible parts if it is possible to recognize the manufacturer or specific model. If still uncertain, consider contacting customer support for the meat mincer brand owner. Provide any detected model numbers, brand names, or relevance inquestion, so they can recommend suitable replacement components matching that particular machine.

-

Quality and material:

Prioritizing quality of parts for a meat mincer is important beyond just ensuring a proper fit. The materials used in construction significantly impact durability, performance, and food safety. Select replacement parts made from high-grade stainless steel and foodsafe plastics or rubber materials. Stainless steel offers superior resistance against rust, corrosion, stains, and damaging impacts. It also endures regular sanitizing without degrading over time. Using mincer parts built with safe plastics designed for contact with food protects against chemical leaching or toxic substances that could contaminate ingredients. These quality materials allow meat grinding machines to maintain optimum hygiene standards while lasting for years of continued service. Assessing the quality of metal and plastic used in part construction is just as important as ensuring compatibility with specific models. Choosing well-made, durable materials lets users depend on their meat grinders safely processing any required quantity of fresh meats without failure or risk.

-

Maintenance and support:

It is more convenient to select parts for a meat mincer that come with good customer support and are simple to maintain. When manufacturers provide warranties and responsive services, users can quickly resolve any problems if the replacement parts malfunction or have fitting issues. This minimizes downtime for grinding meat. In addition, choosing spare parts that require little maintenance helps keep meat grinders running smoothly with no disruptions. Opting for parts where manufacturers commit to proper functioning and assist when needed allows the mincing process to continue uninterrupted. Incorporating easily maintained, warrantied components into the machines keeps them working well while reducing user effort. The upfront investment in quality backed up by support pays off through uninterrupted grinding.

Q and A

Q1. What are some common defects in meat mincers?

A1. Some common defects in meat mincers are motor failure, gearbox problems, damaged blades or plates, rust and corrosion, faults in electrical components, broken handles, and cracks or dents in the housing.

Q2. How can meat mincer spare parts be maintained to ensure longevity?

A2. To maintain meat mincer spare parts, regularly clean them after use, dry all parts completely to prevent rust, use food-grade mineral oil for lubrication, store in a cool and dry place, and avoid using abrasive cleaners that can scratch the surface.

Q3. Are there universal spare parts for all types of meat mincers?

A3. Unfortunately, there aren't universal parts for all meat mincers. While some parts may be compatible with different models, most manufacturers design mincers with specific parts intended only for use with their brand. It is recommended to consult the mincer's manual or manufacturer to determine compatibility.

Q4. How often should blades and plates be replaced?

A4. The frequency of replacing blades and plates depends on their usage. In commercial settings where they are used frequently, they may need to be replaced every year. For home cooks, blades and plates can last several years before replacement is needed. Signs that a blade or plate should be replaced include visible dents or damage, excessive rusting, and poor cutting performance.