All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(3995 products available)

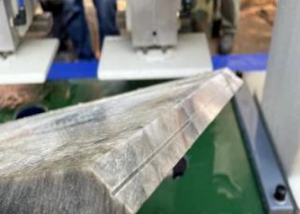

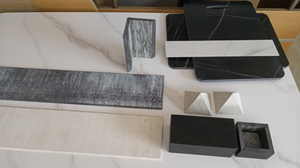

A marble chamfer machine is used on marble stones to make beveled edges. This may involve polishing, roughing, or grinding the edges of marble stones to create a beveled edge (bevels can vary in width). A marble beveller machine can also be used on other types of stones like granite. There are several types of marble beveling machines that perform this task.

Edge polishing machine:

Typically used in the marble and granite industries, this machine can be automatic or semi-automatic. It will usually have multi-use heads that can polish, grind, or roughen edges. Granite edge polishing machines work on the same principle as these machines and may have a different configuration that suits the stone's hardness and characteristics.

Handheld beveling machine:

When a bevel needs to be prepared in precise corners or areas where the marble stone cannot be accommodated, a handheld machine is useful to bevel the edge manually. These machines are lightweight and easy to handle. They may have different attachments and accessories that allow operators to customize the machine according to their requirements.

Edge beveling machine:

This type of machine is not used to polish edges but rather to make beveled edges in marble stones. An edge beveling machine is smaller and more portable. Some may even be compatible with hand routers.

CNC marble chamfer machine:

CNC machines are computer-controlled and highly precise. They can be programmed to create beveled edges with intricate designs and contours. Apart from beveling edges, these machines perform other tasks like boring holes, polishing, and cutting, to name a few. The use of a CNC machine increases production speed and accuracy and reduces wastage in marble stone material.

Automatic marble chamfer machine:

An automatic machine will perform the task of beveling the edge of the marble stone without requiring any manual interference after the settings have been done. The automatic machine is faster than a semi-automatic one depending upon the number of settings and configurations. Most marble polishing machines are semi-automatic or fully automatic.

Specifications are crucial for understanding the capacities of the marble edge polishing machine. Key details include the polishing wheel size, polishing head count, power rating, and voltage configurations.

Replacing the water pump is usually necessary if the machine's cooling system is not working. Check that flexible hoses remain intact and not cracked. The polishing head's bearing can require grease or lubricant over time. Only lubricate if there is a specific grease point. Other parts are generally maintenance-free. Ensure all electric connections are tight.

Repairing parts begins with cleaning the damaged area. Then, use locking compounds to fix slightly loose water pumps or connections, ensuring electric contacts are not blocked. Worn bearing points can be repaired after further inspections. If any major water or electric losses are detected, consult an expert immediately.

Polishing wheel bearings can be serviced with grease, while the marble polishing machine's bearings should be inspected every six months and replaced when necessary. Clean the machine every month so no dust or residues are left after polishing marble pieces. Make use of the manual for specific instructions from the manufacturer.

Marble beveling machines are mainly used in the stone processing industry, but they have many applications in different industries and sectors. Here are some of the common usage scenarios in which marble chamfer machines are used in the stone industry.

Workload demands:

This is the first and most important step in selecting the appropriate marble chamfering machine. Choosing a marble chamfer machine with adequate power and capacity ensures that it matches the workload. Determine the maximum cutting capacity, such as the thickness, length, and width of the stone. Also, consider the required cutting speed and efficiency. For heavy and frequent workload operations, consider choosing a marble chamfer machine with higher power.

Stone type:

Consider the type of stone material to be processed, such as hardness and texture. Different stone materials may require different cutting technologies and blades. Ensure that the marble chamfer machine selected is suitable for the stone material.

Ceremony requirements:

Consider the required chamfering sizes and shapes. Different chamfering dimensions and shapes may require different types of marble chamfer machines. Choose a machine that can meet the desired chamfer sizes and shapes.

Machine quality:

Get a marble chamfer machine that is of excellent manufacture. Consider the machine's stability, reliability, and precision. Research machine brands and user feedback to choose a well-reputed manufacturer.

Operation and control:

Consider the machine's ease of operation and control. Ensure that the chosen machine has an intuitive control system, simple operation, and good safekeeping functions. It should be able to provide reliable controls and set up features for good operational security.

Budget and value for money:

Consider the budget and cost-effectiveness by balancing the quality, performance, and features of the machine. Remember to consider its further maintenance and operating costs.

Q: What are the current trends in marble chamfer machines?

A: Smart technology features like automation are becoming a standard for stone machining tools, including marble chamfer machines. Automation increases efficiency and precision during operation, with marble chamfer machines usually featuring easy-to-use digital control systems that allow device setting and adjustment with little operator intervention. Automation can also be seen in the process of remote monitoring and diagnostics, which enables preventive maintenance and minimizes downtime. Moreover, marble chamfer machines have integrated safety features and systems to avoid operator injuries and accidents.

Q: How long does it take to chamfer marble?

A: The time required to chamfer marble generally depends on various factors like the size and type of the marble piece, the thickness of the bevel, the technique or tool used, and the operator's skill and experience. As a result, it might take anywhere between 10 minutes to a couple of hours.

Q: What is the difference between bevel and chamfer?

A: A bevel is usually referred to as a 45-degree angle cut, while chamfer refers to any other angle that is not 90 degrees. In addition, a bevel is typically applied to items made from solid materials like wood or steel, while chamfers are given to metal pieces to prevent stress concentrations and enhance aesthetics.