All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(91 products available)

A mandrill tool is a hand-operated or machine-powered tool used for drilling holes and for other operations that involve removing material. There are different types of mandrills, which include:

Electric drill mandrill

This is an electric drill that is known for its power and versatility. The electric drill mandrill is used in construction and woodworking for creating holes. It has a chuck that is used for holding drill bits firmly.

Hand drill mandrill

The hand drill mandrill is a tool that is used for making small holes in thin wood. It is simple and easy to use. The hand drill mandrill is used for various woodworking applications like making pilot holes and creating decorative patterns.

Tapping mandrill

This is a tool that is used for cutting internal threads in pre-drilled holes. Tapping mandrills are used in metalworking for enabling the fastening of components. Tapping mandrills come in different sizes and types.

Reaming mandrill

This is a tool that is used for enlarging and smoothing holes that have already been made. Reaming mandrills improve the accuracy and finish of holes. They are used in applications that require precision like in the manufacturing of machine parts.

Rivet mandrill

This is a tool that is used for the installation of rivets in metal components. Riveting mandrills are commonly used in metalworking for the fabrication of structures and in the assembly of components.

Pin vice mandrill

This is a small handheld tool that is used for holding small drills and pins. The pin vice mandrill is used for precision work like in the adjusting of watches and in electronics for the repairing of components.

Collet chuck mandrill

The collet chuck mandrill is a specialized tool that is used for holding bits in a lathe or in a milling machine. It is used for machining operations that require high precision and accuracy.

Material

Mandrill tools are made of high-quality steel, which is durable and has a long service life. Steel is wear-resistant and corrosion-resistant, making mandrill tools last longer.

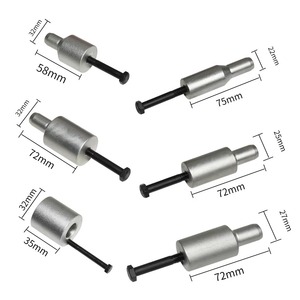

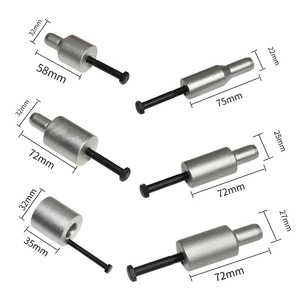

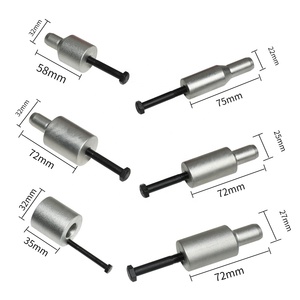

Size

The mandrill tool has various sizes to meet different users' needs. The common sizes are 1/2, 3/8, 1/4, etc. The size of the mandrill tool affects its application range and suitability for different tasks.

Shank Diameter

The shank diameter of the mandrill tool is usually 3mm, 6mm, 8mm, 10mm, etc. The shank diameter should match the user's handpiece or electric drill interface to ensure a firm connection and stable operation.

Cutting Edge Angle

The cutting edge angle of the mandrill tool is usually 60°, 90°, or 120°. The cutting edge angle affects the cutting effect and the tool's applicability to different materials.

Coating

Some mandrill tools have surface coatings, such as titanium nitride (TiN) or carbide (WC) coatings. These coatings can enhance the tool's hardness, wear resistance, and corrosion resistance, thereby improving its service life and cutting performance.

Grinding

Regularly check the mandrill tool for wear and damage. If the cutting edge is worn or damaged, it needs to be ground. When grinding, the angle and cutting edge shape should be ensured to meet the requirements.

Cleaning

After use, the mandrill tool should be cleaned to remove dust, debris, and chips. A clean tool can maintain its cutting performance and extend its service life.

Storage

The mandrill tool should be stored in a dry, ventilated place to avoid dampness and corrosion. Proper storage can prevent tool damage and prolong its service life.

Lubrication

The shank and the connector part of the mandrill tool should be lubricated regularly to ensure a tight connection and smooth operation. Lubrication can reduce the tool's wear and improve its working efficiency.

Inspection

Regularly inspect the mandrill tool for cracks, deformation, and other damage. If any damage is found, the tool should be replaced in time to ensure work safety and efficiency.

Here are some key considerations for choosing a mandrill tool:

Application

Consider the specific application or project when choosing a mandrill tool. Different mandrill tools are suitable for various tasks, such as drilling, grinding, or polishing. Select a mandrill tool that matches the requirements of the job to ensure efficiency and effectiveness.

Material

Mandrills are made from different materials, including steel, tungsten carbide, and high-speed steel. Consider the material of the mandrill tool based on the application and the materials being worked on. For example, tungsten carbide mandrills are suitable for hard materials, while high-speed steel mandrills are appropriate for softer materials.

Size and Compatibility

Choose a mandrill tool that is the right size for the specific task and is compatible with the available power tools or rotary tools. Ensure that the shank diameter and length of the mandrill tool fit securely in the tool's chuck or collet to prevent vibrations and inaccuracies during operation.

Quality and Brand

Invest in high-quality mandrill tools from reputable manufacturers or brands. Quality tools offer better performance, durability, and precision, resulting in consistent and high-quality results. Reading reviews and recommendations can help in selecting trustworthy brands.

Coating and Treatment

Some mandrill tools have coatings or surface treatments that enhance their performance and lifespan. For example, titanium nitride (TiN) coating can improve hardness and reduce friction, extending the tool's durability. Consider the coatings or treatments based on the specific application requirements.

Cutting Edge Design

Mandrill tools come with different cutting edge designs, such as straight, spiral, or ball-nose edges. Choose a cutting edge design suitable for the intended purpose and the level of precision required. For instance, ball-nose mandrills are ideal for contouring and finishing work, while straight edges are suitable for general cutting tasks.

Speed and Performance

Consider the recommended operating speed and performance characteristics of the mandrill tool. Ensure that the tool's specifications align with the capabilities of the power tool or rotary tool being used. Selecting a mandrill tool with compatible speed and performance parameters will optimize cutting efficiency and tool longevity.

Ergonomics and Safety

Take into account the mandrill tool's design, comfort, and ergonomic features. Choose tools with secure grips, vibration reduction, and simple controls for added safety and comfort during operation. Furthermore, consider the safety features of the mandrill tool, such as protective covers or guards, to minimize the risk of accidents or injuries.

Replacing a mandrill tool may seem complicated, but with the right tools and instructions, it can be done successfully. Here are the step-by-step instructions for replacing a mandrill tool:

First, gather the following materials:

Steps:

That's it! The mandrill tool replacement is successful, and the machine or tool is ready to use.

Q1: What is a mandrill tool?

A1: A mandrel is a tool that is used to support workpieces during machining operations. The mandrill tool is a type of cutting tool that is used to create internal cylindrical shapes.

Q2: How does a mandrill tool work?

A2: The mandrill tool is attached to the tool post of a lathe. It is used to machine the internal surface of hollow workpieces. The mandrill tool has a tapered and cylindrical shank that is fitted into a hole in the workpiece. The other end of the mandrill is forced against the internal surface of the workpiece to create the required internal shape.

Q3: What are the different types of mandrill tools?

A3: There are several types of mandrill tools. They include the following: