(1096 products available)

Ready to Ship

Ready to Ship

Mandolin strings are essential to the instrument, as their quality and type significantly affect the sound. Several mandolin strings are available, each offering a unique tone and playability.

Nickel Wound Mandolin Strings

Nickel wound strings are common among electric guitar players. These strings have a round steel core wrapped in nickel wire. The core provides strength, while the nickel wire enhances magnetism and tone. Nickel-plated strings have a tone that's brighter than pure nickel. Also, they resist oxidation and have a longer lifespan than unplated strings. However, these strings are sensitive to sweat and moisture. That makes them dull over time. Additionally, some strings may produce an unpleasant sound when played.

Phosphor Bronze Mandolin Strings

Phosphor bronze mandolin strings sound good for acoustic instruments. These strings have a brass alloy wrapping that contains phosphor and copper. The alloy wrapping improves tonal properties and resistance to corrosion. As a result, these strings last longer and sound good for a long time. Also, the sweet, warm tone of phosphor bronze strings is preferred by many acoustic musicians. However, the strings' warmth may reduce some instruments' brightness.

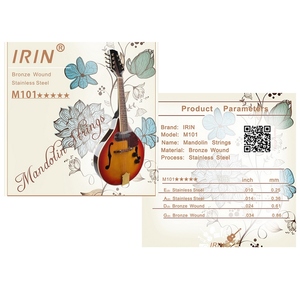

Stainless Steel Mandolin Strings

Stainless steel mandolin strings are similar to nickel strings. They have a round core wrapped in stainless steel wire. The tone of these strings is bright, and they are more durable than nickel-wound strings. Also, stainless steel strings are more resistant to sweat and moisture, making them last longer. These strings are excellent for players who need a sharper tone with a lot of clarity. However, some musicians with sensitive fingers may experience a rash when playing with these strings.

Silk and Steel Mandolin Strings

Sik and steel mandolin strings are wrapped in steel wire and have a silk core. These strings produce a soft tone and are less abrasive on the fingers. They are ideal for fingerstyle and vintage players. Also, silk and steel strings are more flexible, making them easier to play. However, they are less durable and can easily break. Additionally, finding these strings can be challenging.

Flatwound Mandolin Strings

These strings have a flat wire wrap, making them feel smoother. They are quieter and are ideal for jazz and blues music. Also, flat wound strings are more durable and last longer than round wound strings. However, they are less flexible and can be difficult to play.

Round Wound Mandolin Strings

Strings with a round wire wrap are popular among many players. They have a rough texture that gives more friction and better sound projection. The tone of round wound strings is brighter and louder than that of flat wound strings. However, round wound strings wear out faster and can accumulate dirt.

Different types of mandolins are used in different industries. For instance:

When buying mandolin strings for sale, retailers should get various types to cater to different customers' needs. Below are some string factors that customers consider when buying new mandolin strings.

Material

Mandolin strings are available in various materials, such as bronze, brass, and stainless steel. Each string material has a unique sound and lifespan. For example, brass strings have a bright, warm sound and are popular with bluegrass musicians. On the other hand, stainless steel strings offer a powerful and crisp sound, making them ideal for rock and heavy metal music. Retailers should stock strings made from different materials to offer customers options.

Gauge

Gauge refers to the thickness of the strings. Generally, thin strings are easy to play and have a higher pitch than thick ones. In addition, light-gauge strings are more suitable for musicians who play with a pick. Conversely, thick strings are ideal for people who use their fingers or a plectrum. Additionally, heavy gauge strings produce a more powerful sound and are perfect for rhythm playing.

String winding

It is also necessary to get wound and unwound strings. Wound strings are thicker and have a metal wire wrapped around them. Unwound strings are plain and made from a single piece of metal. Both types of strings are essential for constructing a mandolin. However, customers may be interested in different string winding methods, such as round and flat. Round-wound strings have a rough texture and produce a bright sound. Flat-wound strings have a smooth surface and a warm, mellow tone. Buyers should get both types to cater to different customers' needs.

String tension

Strings with high tension require more force to play. Consequently, they are louder and produce a powerful tone. On the flip side, low-tension strings are easier to press. Low-tension strings are ideal for musicians with less playing strength, while high-tension strings are suitable for players with more power.

The features, functions, and design of mandolin strings are as follows:

Durability

Strings for mandolins are constructed to be durable. They are made to handle the tension of playing and tuning, and they resist wear and tear from frequent playing. They stay in tune for longer periods since they are less prone to corrosion or damage. Musicians can play without frequently replacing the strings, resulting in a consistent and improved performance.

Sound Quality

The sound of the mandolin is significantly influenced by the strings. They produce a bright, clear tone that is full of life and depth, enhancing the instrument's distinctive sound. Some strings have coatings that improve tone quality by minimizing unwanted harmonics and maximizing tonal clarity. High-quality strings maintain their sound for longer, giving the mandolin a consistent and professional sound.

String Gauges

Strings for mandolins come in various sizes, with lighter strings being easier to play and heavier strings producing a deeper sound. Players may select the appropriate string gauge to suit their playing style and ability. Lighter strings are easier to press and shift, while heavier strings can withstand increased playing force and tension.

Tuning Stability

Strings for mandolins are constructed to be durable. They are made to handle the tension of playing and tuning, and they resist wear and tear from frequent playing. They stay in tune for longer periods since they are less prone to corrosion or damage or damage. Musicians can play without frequently replacing the strings, resulting in a consistent and improved performance.

Coated Strings

Some mandolin strings have a thin layer of coating that increases their lifespan by providing protection against corrosion and wear. This coating also helps to improve sound quality by reducing unwanted overtones and preserving the strings' tonal brightness. Coated strings require less maintenance and stay in tune longer, making them ideal for musicians who perform in various conditions.

Q1. How often should mandolin strings be changed?

A1. It depends on how often the instrument is played. It can be from a few days to a few weeks. But when visible signs of wear or tear on the strings appear, or when the sound quality declines, it is time to change the strings.

Q2. How can one tell what type of mandolin string to use?

A2. Look at the owner's manual for the mandolin. If it is not available, consult a music equipment expert. The best strings to use will depend on the type of mandolin, playing style, and sound one wants.

Q3. What are some signs that a mandolin string is worn out?

A3. Worn-out strings look dull and rusty. They may have some bumps or corrosion and feel rough when touched. Worn-out strings can also sound out of tune, and the sound is less bright and clear.

Q4. How can one clean mandolin strings?

A4. Use a soft cloth to wipe the strings after playing. This helps remove sweat and dirt. One can also use cleaning products specifically made for string instruments. Cleaning the strings prolongs their life and keeps the fretboard in excellent condition.