Main Parts of a Turbocharger: An Overview

Turbochargers are essential components in modern internal combustion engines, enhancing performance by increasing the engine’s air intake, thereby facilitating improved combustion. Understanding the main parts of a turbocharger is crucial for anyone involved in automotive engineering, maintenance, or performance tuning. This comprehensive guide will explore the primary components, their functions, and the benefits they bring to vehicle performance.

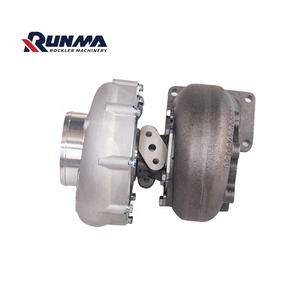

Types of Main Parts of a Turbocharger

The main parts of a turbocharger can be categorized into several key components, each having a distinct role in the turbocharging process. These are:

- Turbine Housing: This encases the turbine wheel and directs the exhaust gases that spin it, converting kinetic energy from exhaust into mechanical energy.

- Turbine Wheel: A critical element that rotates when exhaust gases strike its blades, leading to increased airflow and boost pressure.

- Compressor Housing: This part houses the compressor wheel and warms and pressurizes incoming air before it enters the engine.

- Compressor Wheel: Responsible for drawing in air and compressing it before sending it into the engine, enhancing the engine's overall power output.

- Center Housing: The core component that connects the turbine and compressor sides while also housing the bearing system ensuring smooth rotational movement.

- Wastegate: A valve that controls the flow of exhaust gases to the turbine, regulating boost pressure to prevent over-boosting.

Function and Feature of the Main Parts of a Turbocharger

The main parts of a turbocharger work in unison to optimize engine performance. Here’s how they function and what features they provide:

- Boost Generation: The turbine section harnesses exhaust energy, while the compressor boosts ambient air pressure, allowing for increased power outputs.

- Efficiency Improvement: These components significantly enhance the engine's thermodynamic efficiency, making it possible to generate more power without increasing fuel consumption.

- Minimized Turbo Lag: Advances in turbocharger design, such as variable geometry and twin-scroll configurations, minimize turbo lag, leading to quicker throttle response.

- Durability and Heat Resistance: High-quality materials ensure that parts, especially the turbine and compressor wheels, withstand extreme temperatures and continuous operation.

- Modular Design: Most turbochargers are designed for easy disassembly and replacement of individual components, facilitating maintenance.

Applications of the Main Parts of a Turbocharger

The main parts of a turbocharger find applications across various sectors, primarily due to their ability to enhance engine efficiency and power. Key applications include:

- Automotive Industry: Turbochargers are widely used in performance vehicles, performance upgrades, and in many standard gasoline and diesel engines, enhancing their power-to-weight ratio.

- Heavy-Duty Vehicles: Truck and bus manufacturers utilize turbocharging to improve engine torque and efficienc,y making them ideal for hauling and towing applications.

- Aerospace Engineering: Turbochargers help aircraft engines achieve higher altitude performance by increasing air pressure in the combustion process.

- Marine Applications: Turbocharging is employed in marine engines for boats and ships to improve speed and fuel efficiency on the water.

- Industrial Machinery: Turbochargers are integral to heavy machinery and generators, improving their performance and reliability in demanding environments.