(4757 products available)

There are many types of MACH 3 CNC controllers, including the controller software, USB controller, breakout boards, integrated controllers, and wireless controllers.

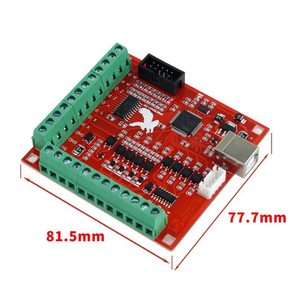

The Mach 3 controller specifications depend upon the type and model of the controller being used. In general, the specs of a Mach 3 controller involve its connection type, number of controlled axes and motors, PC compatibility, operating system, orientation of workpieces, size, and following a particular protocol.

Mach 3's main specifications are as follows:

To keep the machine and the controller in good working condition, make sure to follow some routine maintenance tips and tricks. This will also extend the life of the machine and allow it to work better and more smoothly.

The application scenarios of the Mach 3 controller are closely related to the usage of CNC machines. Here are some typical scenarios:

CNC milling machine control:

The Mach 3 controller can be used to manage CNC milling machines, including adjusting the tool path, speed, and feeding rate. It also facilitates complex machining operations such as milling, drilling, and cutting, thereby providing precise control of the machining process.

CNC lathe control:

The controller is applicable in controlling CNC lathes, enabling operations such as turning, threading, and boring. Users can utilize the Mach 3 controller to script CNC lathes to produce various cylindrical components, shafts, and pipes, among others.

CNC engraving machine control:

The Mach 3 controller can be employed to control CNC engraving machines for carrying out tasks such as engraving, marking, and etching on diverse materials. Users can utilize the controller to create exquisite designs and patterns on the surface of the workpieces.

CNC plasma cutting control:

The controller is capable of controlling CNC plasma cutting machines, allowing users to carry out precision cutting of metallic materials such as carbon steel, stainless steel, and aluminum, among others. The controller provides the user with complete control over the plasma cutting path and parameters.

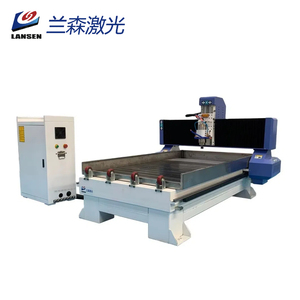

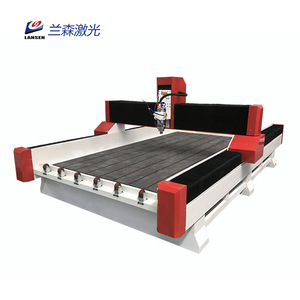

CNC router control:

Mach 3 controllers can be used to control CNC routers to handle a range of tasks such as cutting, carving, and drilling on materials like wood, acrylic, and marble, among others. They are also suitable for applying to the woodworking industry and decoration industry.

CNC laser cutting control:

The controller is usable for controlling CNC laser cutting machines. It enables precision cutting, engraving, and marking on various materials such as metal, acrylic, and plastic, among others, with high accuracy and minimal deformation.

When purchasing a Mach 3 CNC controller, a few key features should be looked at to ensure it will suit the intended requirements and how the user plans to interface with the machine. These include the hardware and interface connection, stepper and servo motor compatibility, breakout and drive systems, wireless controller, and human-machine interaction (HMI).

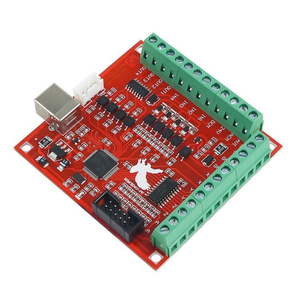

The hardware and interface is the first thing to consider when choosing a Mach 3 CNC controller, as there are different types and versions available. The computer-based Mach 3 controller uses a parallel port to connect to the machine, and a PC with Windows XP and an external motion controller will have to be used. Other hardware versions available are USB, Ethernet, or Smooth Stepper interface controllers. EtherNet controllers are more reliable and achieve higher speeds than parallel ones, while the USB ones are more convenient and easier to set up. EtherSmooth controllers, also an impulse controller, are housed in a single housing unit that includes all the electronic parts needed to make a CNC machine work. Smooth stepper motion controllers convert the movement of digital signals into physical movements of the CNC router parts.

Another important consideration when purchasing a Mach 3 router controller is whether it will work with a stepper or servo motor. Stepper motors are more prevalent and move in distinct steps, while servo motors move in a smoother and more continuous motion. An impulse controller is also more suitable for connecting to a servo motor because it can manage the higher levels and demands of them.

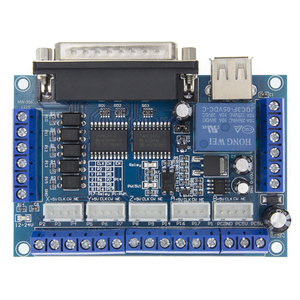

Mach 3 CNC controllers also have a breakout and driving system that will need to be compatible and considered when purchasing one. A breakout board's function is to break out the signals to be used and amplify them so that they can drive the motors.The breakout board will connect to the motor driver, which will then connect to the motor. The motor driver receives the amplified signal and decides how much power it needs to drive the motor.

A wireless Mach 3 CNC controller is a new technology that has recently entered the market, and it uses Wi-Fi to connect to the computer. It eliminates the need for cables running between the devices by using Wi-Fi. However, please be aware that the wireless system may have latency issues. These types of controllers can be quite costly compared to other types.

The last thing to look at is how the user will interact with the CNC machine. Human-machine interaction (HMI) refers to the way a person communicates and connects with a machine. In the case of the CNC router, the person will manually input commands for the machine to follow. The Mach 3 controllers come with different types of HMI to consider, like wireless remotes or touch-screen panels. Other remote types are joystick controllers CNC Mach 3 or smartphone applications. It's essential to consider the kind of remote needed to use the machine before purchasing a controller.

Q: Which controllers are compatible with Mach3?

A: Many USB motion controllers work with Mach3. Some examples are the Tmotion TB6560 (USB), the Tmotion KH540 (USB), and the Smooth Stepper USB Controller.

Q: Why do people still use Mach3?

A: People still use Mach3 because they are satisfied with its performance, familiarity, and reliability. Moreover, Mach3 offers robust support for 3- to 4-axis routers, lathes, and mills. Some advanced features include breakpoint processing, virtual axis, spindle contol, and more.

Q: Can Mach3 control an automatic tool changer?

A: Yes, Mach3 can control an automatic tool changer. Using the proper tool changer and spindle, Mach3 can change tools automatically during a program run.

Q: Is it possible to have a G-code interpreter in the hardware controller?

A: It is possible but not common. Most controllers use a simplified instruction set to maximize speed and efficiency. Some advanced CNC controllers do implement a G-code interpreter.