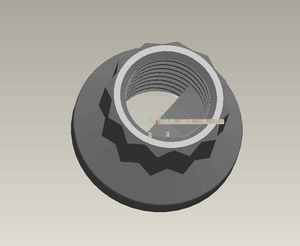

Overview of M10 x 1.25 Nut

The M10 x 1.25 nut is an essential component in various industries and applications, providing a reliable way to secure threaded fasteners. With a metric designation, it conveys critical measurements that validate its fit with an M10 screw, with a pitch of 1.25 mm. This type of nut is particularly popular in automotive, construction, and machinery sectors for its robustness and reliability in holding parts together under various stress conditions.

Types of M10 x 1.25 Nuts

There are several types of M10 x 1.25 nuts available, each serving specific applications:

- Hex Nuts: These are the most common design, featuring six sides and allowing for easy gripping and tightening with standard wrenches.

- Lock Nuts: Designed to prevent loosening due to vibration, these nuts usually feature additional locking mechanisms, making them ideal for dynamic applications.

- Flange Nuts: With a broad flange that acts as an integrated washer, these nuts provide increased surface area and resistance to loosening caused by vibrations.

- Cap Nuts: These are dome-shaped nuts used primarily for aesthetic purposes, shielding exposed threads while providing a finished look.

Applications of M10 x 1.25 Nuts

M10 x 1.25 nuts find application across diverse sectors due to their durability and versatility:

- Automotive: Used in vehicle assembly for securing components such as exhaust systems, engine mounts, and chassis assemblies.

- Construction: Integral for fastening structural components, scaffolding, and other load-bearing installations in building projects.

- Machinery: Vital in agricultural equipment and industrial machinery where secure connectivity under load is critical.

- Aerospace: Employed to ensure reliable fastening in aircraft parts, where weight and strength are paramount.

Advantages of Using M10 x 1.25 Nuts

Choosing M10 x 1.25 nuts comes with various benefits that enhance performance and reliability:

- Standardization: Being a metric component, it aligns with international standards, ensuring compatibility and ease of procurement.

- Strength and Durability: Made from high-quality materials such as steel, aluminum, and sometimes brass, these nuts exhibit excellent tensile strength and resistance to corrosion.

- Ease of Use: The hexagonal shape allows for quick and easy installation and removal, which saves time during assembly or repairs.

- Cost-Effective: The availability of M10 x 1.25 nuts in bulk makes them a budget-friendly option for various industries, reducing overall project costs.