(1411 products available)

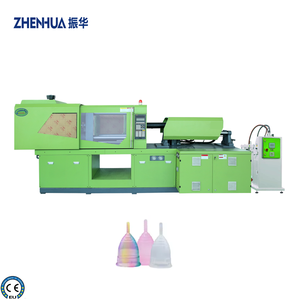

Buyer LS & R Moulding refers to the process of making LSR using heat and pressure. Upgraded designs of the machines also make use of vacuum to create items of different shapes and sizes. The LSR material is heated before being injected into the mold, where it cools down and takes up the shape of the cavity. Luxury cars usually have silicone rubber in various forms for luxury amenities such as sunroofs, cup holders, etc. Pay LS & R Moulding machines are used to manufacture those kinds of parts.

The following types of keyword-focused lsr moulding machines are commonly discussed:

For the effective usage and longevity of any machine, specifications and maintenance play a significant role. Below are some specifications and maintenance tips for LSR moulding machines.

Capacity

It's crucial to know the machine's capacity in liters or kilograms. This information helps business owners to know the amount of excess liquid silicone rubber to feed the machine during production.

Power Supply

LSR machines usually have a specified voltage and frequency. LSR moulding machines have different power demands based on capacity and pressure requirements. It is important to know the machine's power requirements and provide the right type and amount of power to avoid damage or underperformance.

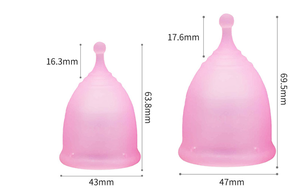

Mould Size

The mould size of an LSR machine refers to the area upon which the silicone material is cast to form the product shape. Different LSR moulding machine types have various mould sizes that relate to their shaping capabilities. Understand the maximum mould size before purchase, as it will help one know the shape that can be formed on the machine.

Mould Temperature

The silicone rubber hardens or cures better when the mould is hot. For this reason, it's imperative to have temperature control in the LSR moulding machine. With temperature control on the mould, operators can adjust the temperature according to the specific requirements of the silicone rubber used. Consistency in mould temperature helps ensure uniform curing, reducing the risk of defects in the finished product.

Machine Cleaning

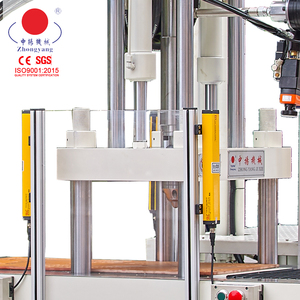

Regular cleaning of the silicone rubber residue is very important for the consistent and smooth operation of an LSR moulding machine. This is because leftover material hardens over time, building up deposits that can lead to clogs and reduced efficiency. Cleaning the machine prevents these negative effects, maintaining optimal performance levels. When doing a regular cleaning wash, it is important to only use clean water and non-abrasive materials to avoid damaging the machine.

Lubrication

Just like any other machine, LSR moulding machines require regular and proper lubrication of moving parts to prevent wear and tear and to avoid any damage. Therefore, it's pertinent to understand the type of oil or grease suited for the machine. Lubrication reduces friction and makes it easy for components to move smoothly.

Due to the adaptability of liquid silicone rubber (LSR) and the effectiveness of LSR injection molding in producing it, the use of LSR molding machines is growing across many industries.

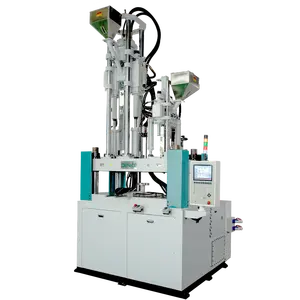

In choosing an LSR machine, the first thing to look at is the type of injection method. A good way to do it is to outline the intended use for a specific type or instance of application. This will help determine what kind of ideal injection method the machine needs to have.

Also, the capacity of the LSR machine also needs to be considered, as it can impact production efficiency and cost. It's important to match the machine's capacity to the scale of production requirements. Think about the sizes of the items to be produced and the volume needed to meet demand. Consider the machine's energy efficiency and operating costs in a long run, too.

When choosing an LSR machine, it's also very ideal to check for additional features and flexibility. This includes the automation level, control system, and any interchangeable tooling or adaptable setups that can enhance the machine's overall versatility.

Lastly, crucial parts of the LSR machine, like the injection system and clamping mechanism, as well as their durability and compatibility with LSR material, should be put into serious consideration, too. The maintenance requirements and support services for the machine can heavily influence its long-term performance and reliability. It definitely helps to research the reputation of the manufacturer and the availability of replacement parts.

Q1: What is the working mold of the LSR machine like?

A1: The working part of the machine is made up of two plates, which have different structures on either side. The pouring side usually has a casting surface put on the plate, and the solidification side will have cooling channels to enable curing.

Q2: What is the working principle of the LSR injection machine?

A2: Liquid silicone rubber moulding machines' working principles are like other injection moulding machines. First, the liquid material is injected into the heated barrel, where it is mixed and heated until it turns into a homogenous liquid. Then, the liquid is injected into the mould at high pressure, forming its shape. The temperature of the mould causes the material to cure and solidify into the final product, which is removed at the end of the cycle.

Q3: How many zones does an LSR moulding machine heating barrel have?

A3: The number of heating zones can vary depending on the size and length of the barrel. Generally, there are 3 to 6 heating zones along the barrel. Each zone has temperature controllers and electric heaters to control the temperature of the barrel precisely.