All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(43971 products available)

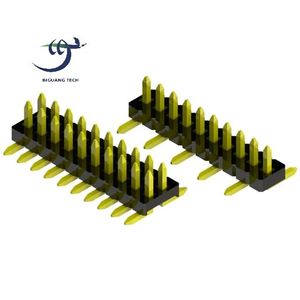

A low-profile header is a kind of connector that is utilized to connect a printed circuit board. It has a shallower profile, making it ideal for spaces that are compact or have a height constraint. Here are different types of low profile pin headers:

This kind of low profile female header is intended for dual or multiple rows. Dual low-profile headers are suitable for joining circuits with complex layouts that require high-density connections. In contrast, multiple low-profile headers can be customized to connect complex circuits that need more signal paths.

Surface-mount low-profile headers are installed directly onto a printed circuit board. They are designed with two or more rows of mating pins that allow them to connect to other components. These headers are commonly used in compact designs due to their pin header low profile.

Vertical low-profile headers have mating pins that are parallel to the printed circuit board's surface. This allows for the placement of daughter cards or expansion boards that are perpendicular to the main circuit board. Conversely, right-angle low-profile headers have mating pins that are at 90 degrees to the circuit board's surface. Hence, these headers are suitable for applications with height constraints.

Shrouded low-profile headers have a covering that protects the mating pins from external interference such as dust or accidental contact. This ensures a more secure and stable electrical connection. These kinds of headers are commonly used in applications where reliability is essential.

Loaded low-profile headers contain additional electrical components like capacitors and resistors. These components help in signal conditioning and improving the signal quality. On the other hand, unloaded headers do not have additional electrical components. They provide a direct connection between the circuit board and the mating component.

Power low-profile headers are used to transmit high current levels from power sources to power distribution boards. The contacts in these connectors are designed to handle high current levels. Signal low-profile headers, on the other hand, are used to transmit signals between different circuit sections. These connectors have contacts that are optimized for low current signal transmission.

Low profile 2.54 mm headers are available in different specifications to suit various applications. Here are some common ones:

Low-profile headers are available in different pin counts to suit various circuit sizes. The pin count can range from 2 to 50.

The distance between pins, known as pin spacing, can also vary. The standard pin spacing is typically 0.1 inches (2.54 mm).

Low-profile headers can be male or female. Male headers have pins that are inserted into receptacles, while female headers have receptacles that accept male pins.

Low-profile headers are mainly made of brass, phosphor bronze, beryllium copper, or other materials. Brass is common because of its low cost and good electrical conductivity.

The pins of low-profile headers are usually plated to enhance their performance. Common plating materials include gold, tin, and nickel.

Headers have a specified current rating, which is the maximum current they can handle without overheating. Current rating can range from 1A to 5A or higher.

Headers have an operating temperature range. The standard range is -40°C to 105°C. There are also some models that can work in extreme temperatures of -40°C to 125°C.

Low-profile headers can be mounted on the surface of a PCB or through-hole. Different types of headers (for example, shrouded headers) are suitable for various mounting options.

The low-profile headers come with an insulator material placed between the headers and the PCB. It also provides electrical insulation and mechanical support to the pins. Common insulator materials are nylon and PBT.

Low-profile headers require some maintenance to ensure they last. Here is a guide to maintaining the low profile header:

When selecting low-profile connectors, it is important to take into consideration the following factors:

It is crucial to consider the application requirements of the low profile pin header. This may involve the pin count, the type of circuit board and the voltage and current requirements. The application should also determine whether standard or specialized headers are required.

Ensure that the low-profile header's electrical specifications are compatible with the application requirements. This may involve the voltage and current ratings of the header, the signal integrity and the impedance matching. Also, ensure that the pin count and the pinout configuration of the header are suitable for the application. This involves ensuring that the low profile header has enough pins for the circuit connections and that the pins are arranged in a way that is compatible with the circuit layout.

Choose a low-profile header with a compatible mounting style. This may involve considering the size and shape of the available mounting space. It also involves considering how the header will be mounted on the circuit board. For instance, it may involve considering whether the header needs to be surface mounted or through-hole mounted.

When selecting a low-profile header, it is important to consider the contact plating. This is because the contact plating affects the header's performance and reliability. For instance, plating materials such as gold and tin protect the contacts from corrosion. Also, ensure that the contact plating is compatible with the materials of the connected components.

When choosing a low-profile header, it is crucial to consider the current carrying capacity. This is because the current carrying capacity should be able to handle the maximum current requirements of the application. It is also crucial to ensure that the current carrying capacity of the header is compatible with the connected components. This is because the current carrying capacity of the connected components should be compatible with the header.

When selecting a low-profile header, it is crucial to consider the environmental factors. This is because the header should be able to operate in the environmental conditions of the application. For instance, the header should be able to operate at the temperatures and the humidity levels of the application. It is also crucial to consider whether the header requires additional protection from environmental factors.

Replacing a low-profile header connector is a delicate process that requires attention to detail.

Wrench: For removing the retaining bolts that secure the header to the exhaust. Screwdriver: Used to remove any heat shields or covers that may be covering the header. Socket wrench set: Used for loosening and tightening the fasteners that secure the header to the engine.

First, the negative terminal of the car's battery should be disconnected. This is done to prevent any electrical shorts or accidents that may happen during the process.

This step requires removing the old header carefully. The fasteners that hold the header to the engine and exhaust system are loosened. Once they are loose enough, the header is removed from the engine.

Once the old header is removed, the surface where the new header will be installed should be cleaned. Any dirt, oil, or residue should be removed to ensure proper fit and sealing of the new header.

The new low profile 2.54 mm header is installed in the reverse order of the removal process. It is carefully aligned and attached to the engine using the fasteners. The torque specifications for the fasteners should be followed to avoid over-tightening or under-tightening. Once the new header is properly installed and aligned, the car's battery can be reconnected. At this point, the vehicle should be started and listened to for any exhaust leaks.

After the installation process is complete, it is important to check for any exhaust leaks. This can be done by feeling around the header while the engine is running to see if there is any exhaust gas escaping. If any leaks are found, the fasteners can be tightened further.

Once the new header is securely installed, any heat shields, covers or underbody panels that were removed should be reinstalled.

After the installation process is complete, a test drive should be done to ensure that there are no issues and that the exhaust system is functioning properly.

Proper disposal methods should be followed to dispose of the old header legally and safely.

Q1: What is the difference between a low-profile and standard header?

A1: A low-profile header is smaller, with a shallower angle, and is often less effective at eliminating back pressure. This can impact performance.

Q2: What are the benefits of using a low-profile header?

A2: A low-profile header can improve exhaust flow, potentially increasing horsepower and torque. It may also reduce weight and improve the vehicle's sound.

Q3: Will a low-profile header fit any car?

A3: No, a low-profile header is designed for specific vehicles. It must match the engine type and exhaust system, among other factors, to fit and function correctly.