All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1783 products available)

There are several types of low NOx burners that reduce nitrogen oxides emissions. They work differently and have their own strengths.

Energy:

Low-NOx gas burners are designed to operate on different gas types. Low NOx natural gas burners are made to work specifically with natural gas. On the other hand, low NOx propane burners are made to utilize propane as fuel.

Emission:

It is measured in parts per million (ppm). For example, some burners may be designed to produce less than 30 parts per million of NOx, which is considered to be very low. Other burners can produce less than 40 ppm of NOx. To achieve this, some manufacturers use precise combustion control techniques and advanced air-fuel mixing.

Fan:

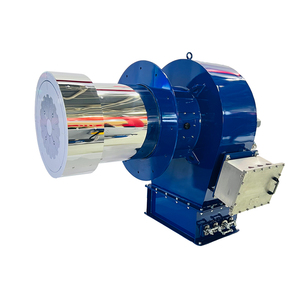

A low NOx induced draft burner uses a fan to pull combustion gases out of the furnace and induce the proper draft for combustion to take place. This is sometimes referred to as a forced draft burner. A low NOx burner with a low external draft design will operate well, even in atmospheric conditions with low combustion gas drafts.

Stages:

Low NOx burners are often designed to have distinct stages of combustion. Some of them may have a two-stage or multi-stage design. Two-stage low NOx burners operate in a high-capacity primary combustion stage and a secondary stage of post-combustion. Multi-stage models have a more complex configuration with several combustion stages. This allows for a more optimized mixing of air and fuel, which in turn helps to reduce the formation of NOx gases.

Regular Inspections:

Carry out routine inspections of the burner components such as air/fuel control valves, mixing assemblies, and tilting mechanisms. Also, look for any signs of gas leakage including hissing noises or unusual smells. If any is found, evacuate the area immediately and seek professional assistance.

Clean the Burners:

As a general rule, avoid the use of abrasive materials or harsh chemicals that can damage combustion surfaces or air passages. Cleaning of low NOx burners can be done with a soft cloth or brush to remove sooty deposits and dirt. Consider using a vacuum cleaner with a soft brush attachment for hard-to-reach areas.

Pay Attention to Air/Fuel Ratios:

Low NOx burners function efficiently when air and fuel are properly mixed. The combustion process will be affected if this is not the case. This can lead to increase NOx emissions, higher fuel consumption and reduced efficiency. Monitor the air/fuel ratio and ensure the actuators and sensors controlling it are functioning properly.

Keep a Log:

It is important to monitor the performance characteristics of the burner system and any maintenance activities performed on it. This information should be kept in a record. If anything goes wrong, reviewing the maitenance log can provide insights into when the problem started and what changes were made just before it arose.

Due to their strict emission standards, low NOx burners have a wide range of application scenarios in many industries.

When it comes to selecting a low NOx burner for a specific project or application, several key factors must be considered. The comprehensive analysis of these factors aids in making an informed decision.

Emission Requirements

Understanding the specific emission requirements is crucial. Determine the allowable NOx emission levels and ensure that the chosen low NOx burner complies with local, regional, or national environmental regulations.

Fuel Type and Availability

Consider the suitable fuels for the burner and their availability. Assess if the site can provide natural gas, oil, biofuels, or other options. Choose a low NOx burner designed for the specific fuel to ensure efficient combustion and emission control.

Operational Requirements

Consider operational requirements such as load range, duty cycle, and operating pressure and temperature. Select a low NOx burner capable of handling the specific operating conditions to maintain performance and control emissions effectively.

Cooling

Evaluate the cooling options. Passive cooling relies on the heat sink effect of the primary combustion zone, while active cooling employs forced convection or water-cooled jackets. Choose the appropriate cooling method based on the burner's thermal management needs and the system's design constraints.

Combustion System Design

Consider the specific design of the low NOx burner. Select a design that meets operational and emission control needs, ensuring proper air-fuel mixing, stable combustion, and optimal thermal performance.

Technology Advancement

When selecting a low NOx burner, it's essential to consider advanced technologies that can further reduce NOx emissions, such as Selective Catalytic Reduction (SCR) or Integrated Gasification Combined Cycle (IGCC) systems. Depending on the project's goals, budget, and feasibility, these technologies may be viable or beneficial options to consider.

Q: Can low NOx burners be used with any type of furnace?

A: Low NOx burner can be used with most types combustors and furnaces. But they are typically coupled with equipment designed to minimize emissions, like scrubbers or diluted baghouses, to meet stringent environmental regulations.

Q: How much low NOx burners reducing is possible?

A: The extent of reduction attainable with low NOx burners depends on several factors, including the initial NOx emission levels, the type and design of the low NOx burner employed, and the combustion adjustment and control technologies used in conjunction with the burner.

Q: Do low NOx burners require special maintenance?

A: While low NOx burners are not typically requiring special maintenance, they may demand more routine after the performance is checked, and some parts are replaced to ensure optimal functionality and emissions compliance.

Q: Can low NOx burners be converted to ultra-low NOx?

A: In some cases, it may be possible to upgrade or convert low NOx burners to ultra-low NOx burners, which typically use additional air staging or external fuel staging to reduce NOx emissions further. Consult with a combustion specialist to evaluate the feasibility of such a conversion for a specific burner and application.