All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(26366 products available)

A low-cost prefab warehouse is a pre-manufactured space that is constructed off-site and delivered to the location for assembly. It is cost-effective, saving time and labor during the construction process. The warehouses are built with standardized parts, which also help cut down costs. A warehouse is a building used for storage, and prefab means pre-manufactured. A storage place that is assembled using pre-manufactured parts is called a warehouse.

The low-cost prefab warehouses come in different types. They include:

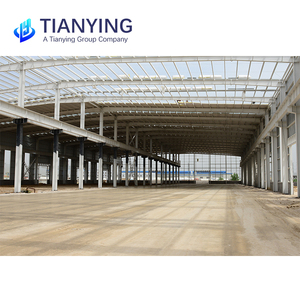

Steel Warehouses

Steel warehouses are low-cost prefab storage places made with a steel frame. They are durable and require little maintenance. The warehouses can be customized to fit specific needs. They are also versatile and can be used for different purposes, such as storing goods, retail space, and workshops.

Metal Storage Sheds

Metal storage sheds are low-cost warehouses made with metal walls and roofs. They are used for storing smaller items that need protection from the weather. The sheds are affordable and easy to assemble. They also have different sizes and designs, which makes it easy to choose one that fits the space available. Additionally, the sheds are secure, providing protection from theft and bad weather.

Aluminum Storage Buildings

These warehouses are made of aluminum. Aluminum is lightweight, which makes it easy to transport. The storage spaces are resistant to rust and aluminum is also available in different colors. Aluminum storage buildings are attractive and can be put in areas with strict rules about how buildings should look.

Container Storage

Container storage warehouses are shipping containers that are used for storage. They are a good way to store items because they are safe and weatherproof. The warehouses are portable, which makes it easy to move them from one place to another. They can also be stacked on top of each other to create more storage space.

Fabricated Storage Building

These warehouses are built using materials like steel and aluminum that are made in a factory. They are strong and can be used for a long time. The warehouses are also versatile and can be used for different types of storage, like retail space, workshops, and offices. They are also easy to customize to fit specific storage needs.

Cost-effective solution:

Prefab warehouses are known for their low construction costs. Because of their economical design and quick assembly, they allow for budget-friendly building options without sacrificing quality. Their prefabricated nature minimizes onsite labor and time, leading to reduced expenses.

Speedy construction:

These warehouses can be constructed in a short time. The components are produced in a controlled environment with precise timing and quality, then delivered to the site for quick assembly. Additionally, the design simplicity and reduced onsite work due to prefabrication contribute to faster project completion.

Environmentally friendly:

Low-cost prefab warehouses are designed to be eco-conscious. The production of warehouse parts uses sustainable practices and materials, and their design often incorporates energy-efficient features such as insulation, lighting, and heating. Moreover, the ability to relocate and reuse these warehouses reduces their environmental impact.

Versatility:

These warehouses have multiple uses, such as storage space for goods, retail space, workshops, and even residential space. Their flexibility in design and function meets various industry needs, from agricultural storage to emergency relief housing.

Durability and strength:

Prefab warehouses are strong and durable due to the robust materials used in their construction, like steel and reinforced concrete. Their design emphasizes resilience, with features such as structural integrity, weather-resistant coatings, and the ability to withstand various environmental stresses.

Customizable design:

A prefab warehouse design can be easily altered to meet different needs and preferences. From the layout, size, and internal fittings, businesses can tailor the warehouse to suit their specific storage or operational requirements. This adaptability makes prefab warehouses a preferred choice for many businesses.

Reduced labor costs:

The controlled environment of warehouse prefab construction minimizes weather-related delays and uncertainties, leading to consistent scheduling and timely completion. Additionally, the efficiency of the manufacturing process and expertise of the workforce contribute to reducing labor costs compared to traditional construction methods.

Despite the misconceptions that have arisen regarding the use of container warehouses, their versatility and convenience make them a preferred choice for many. They are easy to transport, cost-effective and environmentally friendly, making them an excellent option for many industries.

Whether it is a small business looking for a convenient space to operate from or a large-scale project requiring a temporary location, prefab container warehouses are an excellent option.

Some common industries that use prefab container warehouses include:

Choosing the a low cost prefab warehouse that meets one's needs involves careful consideration. Here are some factors to consider when selecting.

Consider The Purpose

Determining the intended use of the warehouse will help one choose a suitable design and size. For instance, a warehouse for retail storage will require different specifications than one intended for manufacturing. Additionally, if the prefab warehouse will need to be customized, it is important to choose a supplier who offers that option.

Check The Location

The location of the warehouse will impact the design and construction. For instance, if the warehouse is to be installed in an area with high winds or seismic activity, it is important to choose a design that can withstand such conditions. Additionally, it is important to consider the local building codes and regulations when choosing a warehouse.

Consider The Size And Layout

It is important to select a size that will accommodate all the intended activities and goods. Additionally, a good layout will ensure the efficient movement of people and goods within the space. This is more important in large warehouses where the inefficient movement can lead to increased costs.

Available Resources

When choosing a low-cost prefab warehouse, it is important to consider available resources. This includes the budget, time, and any other relevant factors. A limited budget means that one will have to settle for a less expensive warehouse. However, this does not mean that it is of low quality. A warehouse made of steel is one that is considered affordable and at the same time durable. Additionally, a limited budget will limit the size of the warehouse.

Check The Quality Of Materials

It is important to check the quality of materials used to construct the warehouse. Good materials ensure that the warehouse is durable and can withstand different environmental conditions. As mentioned earlier, a steel warehouse is durable, and its maintenance is easy.

Check The Construction Time

One of the main advantages of prefab warehouses is that they are constructed off-site and then assembled on-site. As such, they take a short time to be ready compared to traditional warehouses. However, it is important to check the construction time to ensure that it meets the timelines. This is because, in some instances, people want a warehouse urgently. Therefore, knowing the construction time helps one plan accordingly.

Q1: What is the lifespan of a prefab warehouse?

A1: The lifespan of a prefab warehouse depends on several factors, including the quality of materials used, the level of expertise of the assembly crew, and the type of maintenance performed. Generally, a prefab warehouse can last for up to 30 years or more. Steel warehouses tend to have a longer lifespan than wooden ones, sometimes lasting up to 50 years.

Q2: Is planning permission required for a prefab warehouse?

A2: Whether planning permission is required for a prefab warehouse depends on various factors, such as local regulations and the warehouse's intended use. In some jurisdictions, planning permission may not be required for temporary structures or buildings. However, it is advisable to consult with local authorities to determine the specific requirements in your area.

Q3: Can a prefab warehouse be expanded in the future?

A3: Yes, a prefab warehouse can be expanded in the future, depending on the site layout and original design. Some prefab warehouses are designed with future expansion in mind, allowing for easy addition of space when needed.

Q4: Are prefab warehouses energy efficient?

A4: Many prefab warehouses can be energy efficient, especially when equipped with energy-saving features such as solar panels, LED lighting, and proper insulation. The energy efficiency of a prefab warehouse also depends on its design and orientation.