All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(37142 products available)

The following are the types of low-cost 6-axis robotic arm that a business buyer can consider when purchasing these products in bulk.

This is an advanced multi-joint robotic system that uses programmed commands, either manually or automatically. A servo motor controls the motion on each of the six axes in this robotic arm. The functionality allows it to operate with acute precision in diverse scenarios.

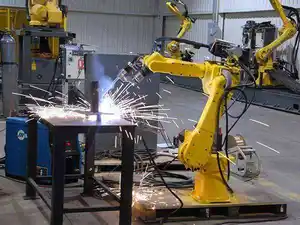

This robotic arm serves various industries, including assembly, welding, and other tasks requiring high force and tight tolerances. The operational speed of the robotic arm makes it valuable for manufacturing sectors focusing on efficiency and consistency. However, the cost of the robotic arm is high due to labor savings and reduction of errors. In the long run, it becomes a low-cost robotic arm.

A brushless motor serves as the driving force behind this robotic arm, offering smoother and highly efficient motion compared to traditional motors. The design gives greater control over the six axes, which makes it ideal for tasks that require precision, like in electronics assembly, painting, or surgery.

It is worth noting that operating requires a higher initial investment than some alternatives. However, the low maintenance costs and lifespan make them a worthwhile investment for long-term use. It is used in environments where there are strict safety or reliability demands. This arm is also used, particularly in aerospace, automotive, and medical sectors.

A pneumatic 6-axis robotic arm uses compressed air to power its movements. This makes it lightweight, efficient, and ideal for applications where speed and flexibility are more important than heavy lifting. Most businesses use it for assembly, packaging, or material handling tasks requiring quick, repetitive movements.

The system's components make the arm more affordable than many electric counterparts. The simple design reduces maintenance and operating costs. Businesses with a large production explosion and high-speed tasks benefit more from this arm.

Technical specifications have to do with the performance and design features of the robotic arm. Here, one needs to consider the application and load of the arm before settling for one. The arm's working environment and control system also have to be factored in.

The six-axis movement offers the arm a high degree of freedom. This enables it to carry out complex actions that an industrial robot or a human could easily do. It can be used for such tasks as pick and place, welding, and painting. These are tasks that require precise movements and flexibility.

That is how it comes in handy in electronics assembly, food and packaging industry, or even the automobile industry. This is because these industries need detailed work and flexible operations in restricted or difficult-to-access spaces.

The working payload of a 6-axis robotic arm typically varies between 0.5 kg and 5 kg. Some high-performance models can manage 10 kg or even more. The arms with a lighter payload are meant for handling delicate products like electronic components or fragile items.

On the other hand, those with high payload capacity are basically for heavy components or tooling in industrial settings. Also, ensure there is an even distribution of weight to avoid damaging sensitive equipment with the arm.

It includes the type of programming used to run the arm, either remotely or manually. This is crucial, as the control mode determines the arm's precision and reliability in completing a task. The control system of the arm is programmable. Thus, it can be operated both manually and automatically.

These robotic arms are constructed to operate in harsh conditions, such as in substance handling, outdoor operations, or extreme temperatures. For example, moisture, dust, or chemicals can compromise some parts. The right seal and coating goes a long way in enhancing longevity.

The maintenance schedule takes time and cost into account. Go for models with fewer maintenance demands if the business has limited downtime. Also, choose the robotic arms that are equipped with easy-to-replace components. This will enable the maintenance process to run with fewer interruptions.

These robotic arms are super handy since they can be used for so many different things. Here are the common places where the arms can be used and the jobs they regularly do.

In industries, these robotic arms usually automate repetitive jobs like assembling, soldering, and welding car parts. The arms never get tired of doing the same thing over and over, while humans can get exhausted or bored. By using the arms, companies can help their workers do more interesting jobs.

Also, the arms make work faster and decrease the number of mistakes that happen with the jobs that require many steps. Their speed and accuracy increase production rates, and they work well in the car factories.

The arms are great for working on tiny, complicated products in electronics factories. They can place small parts or join wires while keeping everything precise. Many people program the arms to work with small things that require careful movement.

The arms do the exact same movements repeatedly, which helps reduce errors. They also help speed stuff up, so the phones and gadgets get built quicker. Using these robotic arms lets companies build delicate equipment faster while keeping everything correct. Some of the arms can be controlled remotely, making them perfect for complex assembly operations.

These robotic arms are game changers for doctors. They make surgeries less messy by assisting with tiny cuts. The arms can hold instruments while the human doctors focus on big picture stuff. It helps the doctors work faster and with fewer errors. The patients will also heal faster since the operations are precise.

They are being implemented in fields to help. The robotic arms can harvest ripe crops or even plant new seeds, making farming more efficient. The arms work day and night, ensuring nothing gets missed. Farmers love that the arms lessen the workload and can boost crop output. Getting quick harvest support means farmers don't stress about weather timing.

The robotic arms assist in food prep tasks in commercial kitchens. They chop, mix, and even assemble sandwiches, leading to consistent food quality. These arms don't need breaks, so meals get finished faster. With fewer hands needed in the kitchen, restaurants can stay efficient during busy rushes.

These arms are helpful in science labs too. They manage tiny liquid amounts for experiments, which speeds up research. The precision of robotic arms means no drops get wasted during experiments. Researchers are happy because they get quicker answers and don't have to deal with tedious tasks.

Families should also think about how much the robotic arms can evenly share weight. This matters if the arms carry anything really heavy. If the load is balanced, everything will stay steady, and tasks will finish faster.

If a family sometimes needs to set the robotic arms for different jobs, then choosing a flexible model is smart. Some arms can twist in different ways to complete many tasks. Flexibility lets the arms fit into small spots or adjust easily. This option is actually quite useful for changing workers.

Families should decide whether they want to run these arms directly or program them ahead of time. This control choice will affect how well the arms manage tasks. Some robotic arms have very simple controls. This is an advantage because the arms are easier to use for beginners. But running them will take extra time.

People should check if these robotic arms can handle tough jobs. Some models are strong enough for regular manufacturing work. Others withstand chemicals on farms or medical centers. Strong materials ensure nothing breaks. This helps the arms last many years.

If tasks call for exceedingly tiny movements, getting a precise robotic arm is best. These arms ensure everything stays in the right spot while working. This precision makes tasks finish faster. Buildings will also appreciate how few errors occur.

Maintenance is another thing families should think about. Some robots need a lot of care, while others are low-maintenance. It is also important to check how much replacement parts will cost. Choosing robotic arms that require little upkeep means they can stay in action longer.

A1. The typical working radius of these robotic arms varies a lot. Some have short reaches under 1 meter for small tasks in factories. But the large ones can stretch over 2 meters, handling bigger items. The exact reach depends on what job the arm needs to do.

A2. Families should check what materials the robotic arms have before using them outside. Some models are built with strong materials that won't rust from rain. These are great for outdoor jobs. But others might not handle weather very well. The durability of the arm will guide whether it can work outside.

A3. The precision really depends on what kind of arm it is. Those with more advanced controls are usually the most accurate. They help during high-precision tasks like surgery. Families should check how precise each model is before buying. This number ensures there won't be errors during important jobs.

A4. Battery life will depend on how much people use the arms. If they run all day, the batteries might need recharging in 8 hours. But light use could make them last over a day. It is crucial to consider how long the arms will stay in action. This factor helps determine if the battery will be enough.

A5. The main advantage of 6-axis arms is their flexibility. They can twist and turn, doing complex jobs well. The previous models only had 5 axes. The added axis provides greater movement capability and a more human-like range of motion. Complex tasks also require less force to accomplish.