(1176 products available)

A lithium battery pilot line is a manufacturing line used to produce lithium batteries in small quantities for testing and validation before large-scale production. These pilot lines help optimize the production process, ensuring quality, efficiency, and safety when transitioning to full-scale manufacturing. Depending on the focus of the pilot line, there are several types of lithium battery pilot lines.

Pilot Lines by Battery Chemistry

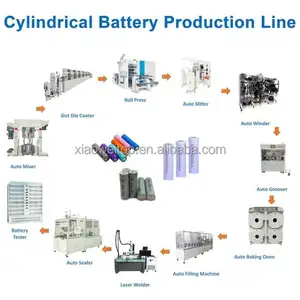

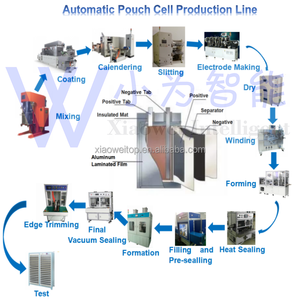

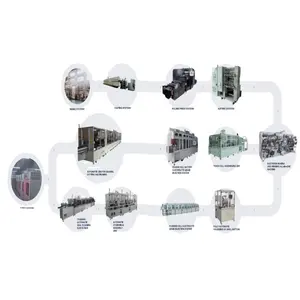

These pilot lines focus on specific types of lithium battery chemistry, such as lithium-ion, lithium polymer, or lithium iron phosphate. Each battery chemistry has unique manufacturing requirements and processes, leading to distinct pilot lines. For example, a lithium-ion battery pilot line might include coater machines for the slurry coating of electrodes, while a lithium iron phosphate battery pilot line might have different machining for cathodes.

Pilot Lines by Production Scale

Small-scale pilot lines are designed to produce limited quantities of lithium batteries, typically ranging from a few hundred to several thousand units per batch. These small-scale lines enable companies to quickly iterate on their manufacturing processes and make necessary adjustments before diving into large-scale production. On the other hand, medium-scale lithium battery pilot lines strive for a balance between small-scale and large-scale production. They tend to produce more significant, yet still manageable, quantities of batteries. These medium-scale lines are often used by companies that already have some experience in lithium battery production and are looking to refine their processes further.

Tecnology-focused Pilot Lines

Some pilot lines concentrate on developing and refining specific manufacturing technologies for lithium batteries. For example, a pilot line that focuses on electrode coating may have experimental coaters that try out different coating techniques or chemistries. Other examples of technology-focused pilot lines include bonding, cell assembly, and cell formation and testing.

To optimize battery performance and lifespan, clients must understand the proper maintenance of batteries produced by the lithium ion battery pilot line.

With the rapid development of new energy applications, the demand for lithium batteries is increasing day by day, and the market is constantly expanding. In this context, the lithium battery pilot line plays an increasingly important role in ensuring product quality, improving production efficiency, reducing production costs, and accelerating product commercialization.

At the same time, the quality inspection and testing equipment of the lithium battery pilot line can ensure product quality. The quality of lithium batteries directly impacts the performance and safety of the final product. Using quality testing and inspection equipment, businesses can identify defects and potential risks early in the production process, ensuring that only high-quality products are put on the market.

Moreover, the lithium battery pilot line can improve production efficiency. In today's fast-paced business environment, increasing production speed and reducing production time are crucial for staying competitive. The pilot lines allow for the simultaneous processing of multiple production steps, streamlining the entire production process and significantly reducing production time.

Also, using a lithium battery pilot line can lower production costs. Raw material waste is one of the main factors driving production costs. The design of pilot lines maximizes material usage through optimal layout and efficient processing methods, thereby reducing raw material waste and significantly lowering production costs.

Finally, the lithium battery pilot line can help businesses rapidly respond to changes in market demand. Market demand is constantly changing, which requires businesses to be able to quickly adjust production capacity and product specifications to meet different market needs. The pilot lines provide businesses with the flexibility to quickly adjust production processes and lines, thereby rapidly responding to changes in market demand.

Battery type:

There are several kinds of lithium batteries, including lithium iron phosphate batteries, ternary lithium batteries, and lithium manganese dioxide batteries, each with its own features and applications. Select a battery type that fits certain product requirements, like lifespan, energy density, and temperature range.

Battery capacity and voltage:

Consider the required capacity and voltage. It's important to choose a battery with the appropriate capacity to meet usage needs. Also, make sure the voltage of the battery is compatible with the devices.

Battery performance:

Include discharge performance, cycle life, and temperature characteristic, etc. For instance, some applications may require high discharge rates; others need long cycle lives. Battery performance should match specific application requirements.

Safety and reliability:

Choose batteries that have passed safety certifications, such as UN38.3, and ensure they have reliable protection mechanisms, like overcharge/over-discharge/over-current/over-temperature protection, etc.

Supplier:

Pay attention to the battery manufacturer's reputation and product reviews. Select well-known brand manufacturers to ensure product quality and after-sales service.

Cost performance:

Consider the trade-off between cost and performance. It's not always the best choice to pick the most expensive batteries; instead, go for those that offer a reasonable balance of cost and performance.

Q1: How many cycles can lithium-ion batteries endure on the pilot production line?

A1: Lithium-ion batteries can typically withstand 500 to 1,500 charge and discharge cycles before their capacity diminishes to about 70% of the original.

Q2: What kind of quality control is there on the lithium battery pilot line?

A2: In the lithium battery pilot lines, quality control is usually done at every production step. It includes materials, process control, and final product inspection.

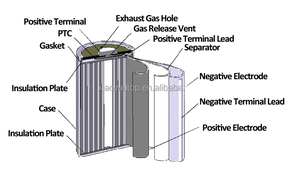

Q3: What are the main components of a lithium battery?

A3: A lithium battery's primary components are the anode, cathode, electrolyte, separator, and battery management system (BMS).

Q4: Is there a specific storage requirement for lithium batteries?

A4: Indeed, lithium batteries must be stored in a cool, dry environment away from extreme temperatures and humidity. Also, they should be stored in the charge state range of 30%-80%。