(898 products available)

Linx coding machines are vital in various industries for printing information such as expiry dates, manufacturing dates, barcodes, and other essential information on product packages. There are different types of coding machines.

Inkjet Coding Machines:

These machines work by propelling tiny droplets of ink onto a product's surface to create clear and high-resolution prints. They are suitable for printing on various materials, including cardboard, plastic, and glass. Additionally, they are compatible with different types of inks for customized branding.

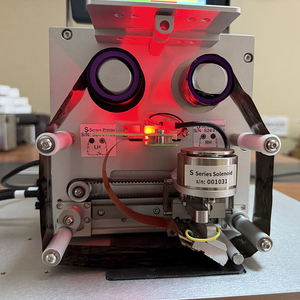

Laser Coding Machines:

They work by etching or engraving a logo or any other desired information onto a product's surface using a highly focused beam of light. They are ideal for creating permanent prints on various materials, including plastic, metal, and wood. Linx laser coding machines include the models below:

F30i Compact Laser Coding System:

This system is intended for use in product coding and marking. It features a compact design that integrates easily into production lines and can be used to mark products with graphs, texts, barcodes, etc. The machine operates at a maximum speed of 3000mm/sec and has a maximum line of 3,000 characters.

F60 Laser Printer:

Linx's F60 is a high-performance laser printer designed to provide precise and clear coding and marking on a variety of materials. The machine excels in delivering durable and tamper-proof markings that are resistant to abrasion, fading, and smudging. It can also be used to mark various characters on products at a speed of 1,500 characters max.

e-Learn ET40 Laser Coding System:

This linx laser coding machine is suitable for coding on bottles. The system can be easily moved from one place to another. It provides a simple interface where the user can code various items with the maximum item speed of 3,000 per hour.

T60 Laser Printer:

Like the F60, the T60 laser printer is optimized for high-speed coding on a variety of materials. It is intended for use in a variety of industries where precise marking is required, such as packaging, manufacturing, and logistics. The Linx T60 marks directly on the surface without the need for inks or transfer materials.

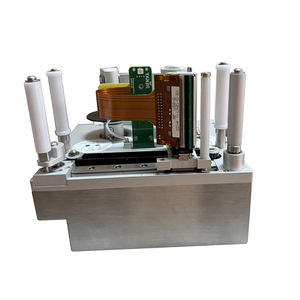

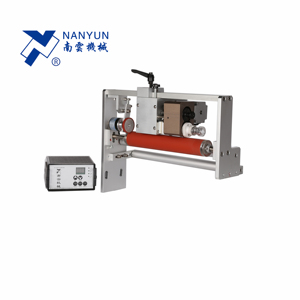

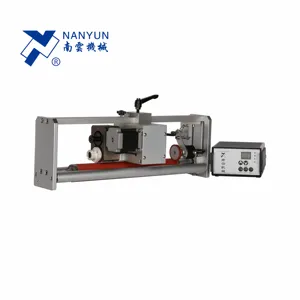

Piezoelectric Tto Coding Machines:

These devices print by transferring ink from a ribbon onto a product's surface using piezoelectric print heads. They are ideal for producing high-quality prints with minimal ink transfer.

Eco-Solvent Inkjet Machines:

They use eco-solvent ink to print on various surfaces, including stickers, labels, and banners. These machines offer high-quality printing and are suitable for producing vibrant colors and sharp images.

Specifications of the Linx coding machines may vary depending on the model and type. Here are some key specifications for understanding their capabilities and features.

Print technology:

Different types of coding machines employ various technologies.

Print formats:

The Linx coding machines offer a variety of print options. Here are a few common types of prints they can create.

Print quality:

Linx coding machines are known for their high resolution and sharp prints, which offer clarity that is important for legible codes. Clients can choose from a variety of resolutions, such as 300 dpi, 600 dpi, and so on. The machine's ability to create crisp, clear editing is crucial for ensuring that the codes produced are easily readable and of excellent quality.

Operating system:

Linx coding machines have user-friendly interfaces with vibrant displays, so users can navigate the printer drivers effortlessly.

Some maintenance practices that Linx coding machine owners can do to ensure their devices always work well include cleaning the machine regularly to get rid of dirt, residue, ink, and other contaminants; checking and changing the parts must be done correctly and on time for optimal performance and reliability of the coding; and keeping the ink level, ribbon status, and printing quality, among other parameters, while also making adjustments as necessary.

Coding machines are used in various industries to print or code on any product, packaging, or materials like wood, plastic, metal, etc. Here's a general breakdown of what products are used and for what industries:

Packaging and Labels:

The food and beverage industry uses coding machines to print dates, nutritional information, barcodes, expiration dates, and product information directly onto packaging and labels.

The Pharmaceuticals Industry:

Coding machines are used to print important information on drug packaging. This can include but is not limited to, serialization, expiration dates, dosage details, and label." With the above coding information, drugs can be tracked, and patient safety is ensured.

Electronics and Automotive:

Coding machines are used in the electronics and automotive industries for part identification, serial numbers, barcodes, and manufacturing information. This can include coding on circuit boards, automotive components, and electronic enclosures.

The Building and Construction Industry:

In building and construction, coding machines are used to mark construction materials (like lumber, metal, and plastic), identify components, or print installation guidelines and logistics information.

The Luxury Goods Industry and Packaging:

"In the packaging industry, luxury goods use a coding machine to identify products, track shipments, and ensure the authenticity. Additionally, they ensure product quality by printing batch numbers on packaging."

Dating and Marking:

Coding machines are widely used in the food and beverage industry for dating and marking. This includes printing production dates, expiration dates, sell-by dates, and lot numbers directly onto packaging, containers, or labels.

The Construction Industry:

In the construction industry, a coding machine can be used to identify construction components, mark materials, or code pipes. This is usually done for tracking, sorting, or ensuring compliance with building codes and regulations.

General Manufacturing:

Coding machines can be used at various manufacturing levels to track products, ensure quality, and facilitate inventory management.

Use the following guiding factors to select an ideal Linx coding machine for business needs from the many available options.

Packaging Material Compatibility

Choose a coding machine that can code the specific type of packaging material used. Consider the machine's coding medium and ensure it's suitable for the required packaging materials. Ensure the coding machine can produce clear and legible codes on the packaging material surface.

Code Requirements

Analyze the code requirements for contracts. Determine the required codes, such as expiry dates, lot numbers, barcodes, or any other specificcoding requirements. Then, choose a coding machine capable of generating the desired codes.

Production Volume and Speed

Select a machine that can handle the required production volume. Also, consider coding speed. Choose a machine with a maximum coding speed that meets or exceeds production line requirements.

Machine Environment

The coding machine's working environment matters. Choose a machine that's well-suited for its typical work environment in a production facility. For instance, if it will work in a dusty or humid place, select an environmental-resilient coding machine.

Maintenance and Support

Consider the machine's long-term maintenance needs and the support available. Opt for a coding machine from a supplier who provides straightforward maintenance instructions, readily available replacement parts, and technical support.

Integration with Existing Systems

Consider the coding machine's integration with existing systems, like production line setup,software, and other equipment. Ensure the coding machine chosen can integrate seamlessly with the existing system and help maintain smooth production operations.

Q1: Which industries mainly use Linx coding machines?

A1: Linx coding machines are widely used in many industries. They are used in the pharmaceutical industry to print vital information such as expiration dates, batch numbers, and manufacturing dates on product packaging, labels, and cartons. In the food and beverage industry, they print details like production dates, best-before dates, and barcodes directly onto food packaging, containers, and labels. Also, coding machines are used in the packaging industry to add labels, barcodes, and product information to packages. Additionally, they are used in the construction industry to mark materials with identification codes, lot numbers, or regulatory compliance information. Lastly, in the textile industry, coding machines imprint requirements like care instructions, product IDs, and brand labels on textiles and garments.

Q2: Can coding machines create barcodes?

A2: Yes. Some coding machines can create barcodes. Barcode printing codes product information in a machine-readable format. Coding machines are capable of printing various types of barcodes. Including linear barcodes like Code 39 and Code 128, as well as 2D barcodes such as QR codes.

Q3: Are coding machine prints durable?

A3: Generally, prints created by coding machines are very durable. They are designed to resist smudging, scratching, fading, and wearing. Also, the prints are able to withstand harsh environmental conditions such as moisture, chemicals, UV light, and extreme temperatures.