All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1934 products available)

LED strip heatsinks are crucial components designed to dissipate heat from LED strips, ensuring optimal performance and longevity. They come in various types tailored to different applications and environments. Here are some common types:

Aluminum Heatsinks

Aluminum heatsinks for LED strips are the most common. They are popular due to their excellent thermal conductivity and lightweight nature. Moreover, they are available in different shapes and sizes, making them versatile for various strip LED applications. Aluminum heatsinks can be passive or active. The passive dissipate heat through conduction and natural convection. The active ones use a fan for forced convection.

Copper Heatsinks

Copper heatsinks are known for their superior thermal conductivity. They are used in applications where efficient heat dissipation is paramount. However, copper is heavier and more expensive than aluminum. Thus, copper heatsinks are often found in high-performance or compact LED strip setups.

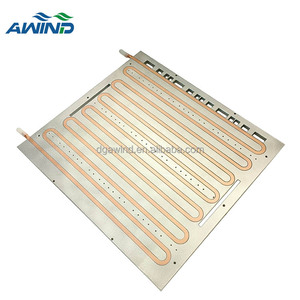

Combination Heatsinks

Some heatsinks combine aluminum and copper to take advantage of both materials. For example, they can have a copper core for optimal heat transfer and aluminum fins for lightweight and effective heat dissipation. This combination provides a balanced performance and can be customized for specific LED strip requirements.

Flexible Heatsinks

Flexible heatsinks are designed for applications where the LED strip is installed on curved or irregular surfaces. They are made from thin, flexible metal sheets (usually aluminum) with a high aspect ratio fin design. This allows them to conform to different shapes while efficiently dissipating heat.

Adhesive-backed Heatsinks

These heatsinks come with an adhesive backing for easy installation. They can be directly attached to the back of the LED strip. They are often made from aluminum and have a simple peel-and-stick design. This makes them suitable for applications where mechanical fastening is impractical.

Active Cooling Solutions

Some high-power LED strips require more efficient cooling solutions. Active cooling solutions incorporate fans or liquid cooling systems. The fans create airflow over the heatsink, increasing the heat dissipation rate. Liquid cooling systems circulate coolant to transfer heat away from the LEDs more efficiently. For instance, in industrial or high-brightness applications, liquid cooling systems may be required.

LED strip heatsinks are essential in maintaining optimal operational temperatures for LED lighting systems. They provide several features and functions that enhance the performance, longevity, and efficiency of LED lighting. Here are some key functions and features:

Heat Dissipation

The primary function of a heatsink is to dissipate heat from the LED strip. LED lights convert electrical energy into light and heat during operation. Excessive heat buildup can negatively impact the performance and lifespan of the LED. Heat sinks absorb and spread the heat away from the LED, releasing it into the air and maintaining optimal operating temperatures.

Material with High Thermal Conductivity

Efficient heat dissipation relies on good thermal conductivity. Heatsinks are usually made of materials like aluminum or copper with high thermal conductivity. These materials allow for the effective transfer of heat away from the LED and dissipation into the environment.

Large Surface Area

Heat sinks are designed with a large surface area to promote airflow and cool efficiently. The increased surface area provides more space for heat to escape into the air, reducing the temperature of the LED strip lights. This is important for maintaining optimal brightness and extending the lifespan of the LEDs.

Active Cooling Options

Some LED strip heatsinks have cooling fans. The fans provide active cooling by continuously circulating air over the heatsink, allowing for more effective heat dissipation. This is particularly useful for high-powered LED strips or applications where temperatures need to be maintained. The fans reduce the chances of thermal throttling, thereby enhancing the performance and efficiency of the LED lights.

Mounting and Integration

LED strip heatsinks have features that enable easy mounting and integration of LED strips. For example, they can have adhesive backing or channels where strips can be inserted. This makes it easy to attach the LED lights to the heatsink for efficient heat transfer. Some heatsinks are specifically designed for certain LED configurations, ensuring optimal contact and thermal transfer.

Durability and Protection

Heatsinks protect LED strips from overheating. By keeping the temperature within safe limits, heatsinks prevent thermal damage to the LEDs. They also prolong the lifespan of the lighting system, ensuring long-term reliability. Some heatsinks have enclosures that protect the LEDs from physical damage and environmental factors like moisture and debris.

LED strip heatsinks are essential for dissipating heat from LED lighting systems. Their applications span various industries and sectors, including:

When choosing LED strip heatsinks, various factors must be considered to ensure optimal performance and reliability. Here are some key points to consider before settling on a particular product.

LED Configuration

The configuration of the LEDs on the strip can influence the type of heatsink chosen. For example, if the LEDs are closely spaced, a flat heatsink might be more appropriate. However, if they are further apart, a ribbed or finned heatsink could suffice.

Ambient Temperature

The environment in which the LED strip will be installed plays a significant role in heatsink selection. If the ambient temperature is high, a more efficient heatsink may be required to dissipate the heat effectively. Conversely, a lower ambient temperature might require a less robust solution.

Power Rating

The power rating of the LED strip is crucial in determining the size and type of heatsink needed. Higher power ratings typically mean more heat will be generated, requiring a more substantial heatsink to ensure proper thermal management.

Material

The material of the heatsink can significantly impact its performance. Common materials include aluminum and copper, which have excellent thermal conductivity. Aluminum is often preferred for LED strips due to its lightweight and cost-effective properties, while copper offers superior thermal performance but can be more expensive.

Size and Form Factor

The size and form factor of the heatsink must be compatible with the available space. Considerations such as the strip's length, width, and any specific design requirements are essential to ensure a perfect fit and optimal performance.

Airflow

If there is natural or forced airflow in the environment, it can influence the type of heatsink chosen. For example, a heatsink might be more efficient in a windy environment, while a more massive heatsink might be needed in a non-air-conditioned space.

Mounting Options

The way the heatsink will be mounted to the LED strip or the surface it will be attached to can influence its performance. Considerations such as adhesive tapes, screws, or thermal pastes should be considered when choosing a heatsink.

Q1: Do LED strip heatsinks have lights of their own?

A1: No, LED heatsinks do not have lights of their own. They are simply designed to cool LED strips by dissipating heat away from them.

Q2: Can LED strips be used without a heatsink?

A2: Technically, LED strips can be used without a heatsink. Nonetheless, doing so will expose them to overheating, which can damage the LEDs and shorten their lifespan. In this regard, using a heatsink to protect the LED lights is recommended.

Q3: How does one install an LED strip on a heatsink?

A3: Installing an LED strip on a heatsink is a simple process. First, one should remove the protective backing from the LED strip. Then, if applicable, one should apply thermal adhesive or tape to the LED strip. After that, position the LED strip on the heatsink and press firmly. Lastly, allow the adhesive or tape to cure if necessary.

Q4: What are the common materials used to make LED heatsinks?

A4: The most common materials used to make LED heatsinks include aluminum and copper. Businesses prefer aluminum due to its lightweight nature and excellent thermal conductivity. Although copper offers superior thermal conductivity, it is heavier and more expensive than aluminum.

Q5: How can one maximize the performance of an LED strip heatsink?

A5: To maximize the performance of an LED strip heatsink, one should ensure proper air circulation around the heatsink. Additionally, one should use high-quality thermal paste or adhesive and keep the operating environment free of debris and contaminants.