(214 products available)

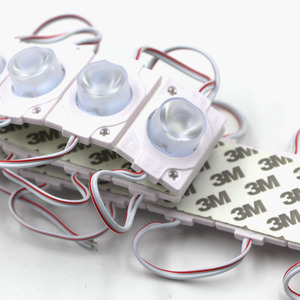

The LED injection mold module is a light source technology that integrates LEDs with molds used for plastic injection. This technology allows for the direct curing of plastics around LEDs to produce lights used in various applications. Injection molding LED modules are widely used in automotive lighting, general lighting, and backlighting. They are categorized based on:

By Packaging Technology

The LED injection mold modules are categorized into different packaging technologies. This involves assembling the LED chip with different components. There are:

COB (chip on board) LED modules - the LED chips are mounted directly onto the circuit board for efficient heat dissipation and high brightness. The LED chips are encapsulated with phosphor and epoxy resins to form a mold that is injected with the LED chips during the process of creating the board. They are preferred because of their high intensity and uniformity of light.

Mid-power and high-power modules - these LED modules use metal-core PCBs. The mid-power modules use up to 1w of power per LED, while high-power modules use more than 1w. The metal core PCBs have good thermal conductivity that helps to dissipate heat and prevent damage to the LEDs.

By LED Chip Configuration

The LED injection mold modules are also classified according to the configuration of the LED chips. This means the arrangement of the LED chips on the board. There are:

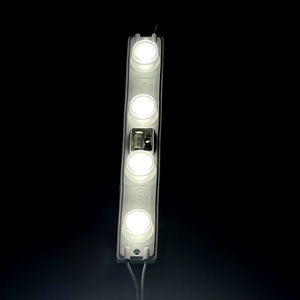

Linear modules - these have a linear configuration of LED chips. They provide uniform lighting along the length and are used in applications like signage and architectural lighting.

Matrix modules - these have a matrix configuration of LED chips arranged in rows and columns. They provide high-intensity lighting and are used in applications like area lighting.

By Application

The LED injection mold modules are also classified according to their applications. Different industries apply them differently. For example, the automotive industry uses them for various applications. They provide lighting for headlights, taillights, brake lights, turn signals, and interior lighting in vehicles. Additionally, they are used in traffic lights and street lighting. This is because they have high visibility and low power consumption. LED injection mold modules are also applied in general lighting. This includes LED bulbs, tubes, panels, and recessed lighting. They offer energy-efficient and long-lasting lighting solutions for residential, commercial, and industrial spaces.

LED injection module molds have several features and functions worth noting. Here are some of them:

Thermal Management

The LED injection module molds come with a thermal management feature. It has heat sinks that are strategically placed around the LEDs. These heat sinks play a critical role in dissipating heat from the LEDs. They ensure even heat distribution. This feature ensures the LEDs maintain optimal temperature. Also, it minimizes the risk of overheating. As a result, the LEDs have a longer lifespan.

Efficient Light Distribution

This feature ensures efficient distribution of light. It allows the LEDs to produce bright and uniform light. This feature is critical in applications where the injection mold needs to display graphics or messages. Efficient light distribution is also important in outdoor signage and lighting.

Modular Design

The LED injection module molds are designed in a modular way. Each module consists of multiple LEDs and a printed circuit board. This design offers flexibility and scalability in the manufacturing process. It allows the production of LED arrays with different sizes and shapes. The modular design improves the ease of customization of the injection molds to meet specific customer needs.

High Precision

The injection molds used in LED lighting are high precision. This ensures that the light produced is consistent and uniform. The high precision feature ensures that there is minimal light loss. This increases the overall efficiency of the LED lighting. It also leads to the production of high-quality lighting solutions with better brightness and longevity.

Versatility

LED injection module molds are versatile. They can be used in different types of LED lighting applications. For instance, in outdoor and indoor lighting. This includes street lighting and architectural lighting. Their versatility allows manufacturers to customize the molds to cater to specific LED lighting requirements.

Durability

These injection molds are durable. They are made from strong materials that can withstand repeated use. Their durability ensures that they provide quality services for an extended period of time. This reduces the need for replacement. Their longevity makes them cost-effective.

LED injection mold modules are widely used in various industries and applications. Here are some common usage scenarios:

Automotive Lighting

Automotive lighting is among the most common usage scenarios of LED injection mold modules. The molds create LED lights for headlights, taillights, brake lights, turn signals, and interior lighting. The molded LED lights provide better visibility and have a longer lifespan.

Consumer Electronics

Molded LED lights are used in consumer electronics like smartphones, tablets, laptops, and television screens. The backlit LED lights enhance display visibility and improve user experience. Molded LEDs are also used in product buttons and indicators.

Appliances

LED injection mold modules are used in various household appliances. For instance, they are used in the lighting of microwaves, ovens, refrigerators, and washing machines. The molded LED lights improve the visibility of appliance controls and compartments.

Commercial Lighting

Molded LED lights are widely used in commercial settings such as offices, retail stores, restaurants, and hotels. The lights provide efficient lighting solutions for task lighting, ambiance, and accent lighting. Molded LEDs are also used in streetlights and parking lot lighting.

Outdoor and Architectural Lighting

LED injection mold modules are used in outdoor lighting applications. These include landscape lighting, pathway lighting, and building facades. The molded LED lights enhance the aesthetics of outdoor spaces and structures while offering energy-efficient lighting solutions.

Healthcare

Molded LED lights are used in the healthcare industry. For example, they are used in surgical lights, examination lights, and medical imaging equipment. The LEDs provide bright, uniform lighting that is necessary for medical procedures and evaluations.

Industrial Lighting

Injection mold modules are used in industrial lighting applications. For example, they are used in warehouses, factories, and manufacturing plants. The molded LEDs provide high-intensity lighting that is necessary for large industrial spaces.

Sports Lighting

Molded LED lights illuminate sports arenas and stadiums. The lights provide bright and uniform lighting for outdoor and indoor sports events. Additionally, they are used in floodlights and arena lighting.

When purchasing LED injection mold modules, there are a few factors that business owners should consider. They include:

Target market needs

Different customers have different preferences when it comes to color temperature, design, and energy efficiency. Therefore, it is important to consider what the target market needs when choosing LED injection modules. For instance, if the target customers are looking for color options, then LED modules that support RGB or RGBW should be considered. On the other hand, if energy efficiency is a priority for the target market, then LED injection modules with a low wattage should be chosen.

Quality of the LED module

The quality of the LED module should be given priority when purchasing. This is because quality determines durability and performance. The LEDs' lifespan and brightness degradation over time are both influenced by the quality of the module. To ensure the quality of the LED injection modules, a good brand should be chosen.

Compatibility

The products that are being injected into the module should be compatible. This is to ensure that the customers' products work well and that there are no issues during the injection process. Business owners should ensure that they understand the requirements of the product they intend to manufacture before purchasing a compatible LED module.

Wattage and power consumption

Wattage is important because it determines the brightness level of the LED injection module. On the other hand, power consumption indicates how much energy the module uses. Customers looking for energy-efficient lighting solutions will consider power consumption when choosing LED modules. Therefore, it is important to consider both power consumption and wattage when purchasing the module.

Q1: What are the injection molding LED modules?

A1: An injection molding LED module is a component consisting of LEDs, a circuit board, and a housing made through injection molding. This module is used for lighting in different applications.

Q2: How does a LED module work?

A2: The LED module works by providing light when electrical current is passed through the LEDs. The module is designed to efficiently produce light for various applications.

Q3: What is the purpose of a LED injection molding?

A3: The purpose of LED injection molding is to create lighting products that integrate LEDs into molded plastic components. This provides design flexibility and improves lighting efficiency.

Q4: What does LED stand for?

A4: LED stands for Light Emitting Diode. These are semiconductor devices that emit light when an electrical current is passed through them.

Q5: What are the types of LED modules?

A5: The types of LED modules include strip modules, flexible modules, and potted LED modules.