Introduction to Lead Free Solder

Lead free solder is a crucial advancement in the world of electronics, necessitating an environmentally friendly approach to soldering. As industries move towards safer alternatives for electronic manufacturing, lead free solder presents itself as an eco-conscious choice that meets regulatory standards. It is primarily composed of metals such as tin, silver, and copper, offering high melting points and excellent bonding properties, which ensures durability and reliability in electrical connections.

Types of Lead Free Solder

There are several formulations of lead free solder available, each designed to suit different applications within electronics manufacturing:

- SnAgCu (SAC) Alloys: Commonly used in various applications, these alloys combine tin, silver, and copper for superior reliability.

- BiSn (Bismuth-Tin): This type is often utilized in specialized environments where lower melting points are required.

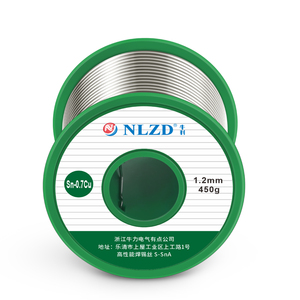

- SnCu (Tin-Copper): This is a cost-effective option primarily used for wave soldering.

- SnZn (Tin-Zinc): A less commonly used alloy, suitable for specific applications and has low melting points.

Applications of Lead Free Solder

Lead free solder has gained widespread acceptance and is utilized across various industries. Here are some of its primary applications:

- Consumer Electronics: Lead free solder is largely used in smartphones, laptops, and other portable devices to ensure safety and compliance with regulations.

- Aerospace and Automotive: Industries where reliability and performance are critical use lead free solder for manufacturing components that can endure extreme conditions.

- Medical Devices: The strict regulations in medical equipment manufacturing often mandate the use of lead free solder to ensure patient safety.

- Renewable Energy Products: Solar panels and other sustainable technologies increasingly utilize lead free solder for efficient and safe energy solutions.

Advantages of Lead Free Solder

The shift from traditional lead-based solders to lead free solder comes with numerous benefits. Here are some advantages:

- Environmentally Friendly: By eliminating lead, these solders reduce toxic waste and comply with global environmental regulations.

- Health Safety: Using lead free solder minimizes health risks associated with lead exposure in workers and consumers.

- Enhanced Reliability: Many lead free solders offer improved performance and longevity in various applications, making them a preferable choice.

- Versatility: Available in different formulations, lead free solder can cater to multiple soldering requirements and preferences.