(872 products available)

![[KOOCU] GF-103 7 Inch <strong>LCD</strong> Separator <strong>Machine</strong> with Build-in Vacuum Pump](http://s.alicdn.com/@sc04/kf/Haacb362fdb4d4184a90ee8d46a1222bfk.jpg_300x300.jpg)

An LCD digitizer separate machine is used to separate the glass from the LCD screen. usually, there are two types of LCD separator machines that are centrifuge separators and vacuum separator machines.

The separator machine with a vacuum method uses a vacuum pump to remove all the air from the chamber. Air inside the chamber causes friction behind the falling glass and the falling weight. The vacuum separator uses gravity to pull the break glass down onto a padded tray. The glass then shatters into more minor shards that can be wiped away. The vacuum machine can separate any digitizer glass from an LCD screen. However, these machines tend to be more costly than centrifuge separator machines.

Centrifuge separator machines use a quick-spinning motion to separate objects. Its fast-moving wheel mixes the liquids within the chamber, causing separation based on density and mass. These separator machines are known to be affordable and easy to maintain. These types of separator machines can separate different sizes of particles, which include micro-sized particles.

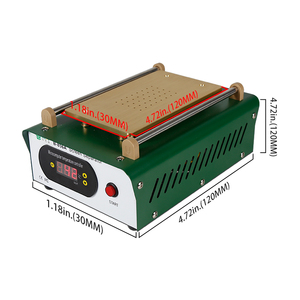

The LCD digitizer separator machine showcases an impressive array of features that enhance functionality, ensure user-friendliness, and prioritize safety. These features collectively contribute to the efficient and effective separation of LCD screens from their frames:

Versatile Heating Options

The heating plates cater to varying needs with precise temperature control, ensuring safe and effective separation of delicate LCD screens. Equipped with multiple temperature-control heating plates – 200℃, 250℃, 300℃, 350℃ – the machine can adapt to different kinds of LCD screens. Operators can choose varying temperatures for heat treatment to separate the LCD screens from frames.

Vacuum Pump

This machine has a reliable vacuum pump that creates a strong vacuum suction. This enhances the successful separation of LCD screens from frames, especially for tightly bonded or damaged screens. The vacuum suction ensures that the fragile screens are separated gently without bending or breaking.

Timer Control

With fixed intervals, the timer control allows users to set and monitor the separation process. This feature ensures consistent results by providing accurate timing for heating, vacuum suction, or any other necessary step during screen separation.

User-Friendly LCD

The LCD interface with intuitive buttons and clear instructions simplifies machine operation. This makes accurate parameter adjustments easy for users, even those with little experience in screen separation. Operators can easily monitor the machine's status, check temperature controls, and adjust timings on the user-friendly display.

Safety First

The LCD digitizer divider machine is designed with operator safety in mind. Features like heat-insulated handles, warning indicators, and emergency stop buttons contribute to a safe working environment. These safety measures minimize the risk of accidents and ensure peace of mind for the users while handling equipment at high temperatures and vacuum pressures.

Sturdy Build

The Separator machine's construction uses high-quality materials to withstand wear and tear from frequent use. This durability ensures that the machine achieves reliable long-term performance and consistently separates LCD screens from frames for an extended period.

Digitizer and LCD separation machines are widely used in various industries, including the following;

When it comes to purchasing an LCD separator machine for business purposes, buyers should consider several factors to choose a model that can suit their needs. These factors include;

Volume and Speed

Users should assess their production volume and pick a machine capable of handling their needs efficiently. For businesses dealing with high volumes, choosing a separator that can operate at a high speed is important to maximize productivity.

Types of Devices

Review the types of devices the business primarily services and choose a separator that is best compatible with those models. If the business handles a wide range of devices, selecting a machine that can work with various types of LCDs is beneficial.

Features and Functions

When looking for an ideal LCD separator, it is important to carefully evaluate the features and functions that can improve efficiency and convenience. For instance, users should look for separators with vacuum pumps that provide strong and precise suction for safe positioning of LCDs. Timer controls are helpful in having consistent processing times for better results. Also, users can improve efficiency and convenience during separation tasks with automatic or semi-automatic operation.

Quality and reliability

Users should choose makers with a reputation for producing high-quality and reliable separation machines. They can read reviews and ratings from other buyers to have a clear picture of the machine's performance and reliability. Choosing a machine with durable construction and components can reduce the need for frequent repairs and replacement. Also, buyers should look for suppliers who offer warranties and after-sale services for their machines.

Budget and Cost

When it comes to choosing an LCD separator machine, buyers should establish a budget and weigh the cost against value. They should carefully consider the separation machine's purchase price, maintenance costs, and energy consumption. This enables buyers to choose a machine that is within their budget and offers great value in the long run.

Q: How to set up an LCD separator machine?

A: Most models come with detailed instructions for installation and operation. It may involve mounting the LCD onto a separator jig, applying vacuum suction, and heating the panel before separating the digitizer.

Q: Is training provided on how to use the machine?

A: Some suppliers provide training to technicians on using the machine. User manuals and machine operation guides are also given to help users learn how to operate the LCD separator.

Q: What maintenance do LCD separator machines need?

A: Regular maintenance keeps the machine running smoothly. This maintenance may include changing seals, cleaning vacuum nozzles, and calibrating temperature controls. Check the user manual for details on maintenance procedures.

Q: How to troubleshoot common separation issues?

A: Various resources help users fix problems that may occur during operation. These resources include machine user manuals, online forums with experienced users, and customer support from the machine supplier.

Q: Can separator machines be upgraded?

A: Some separator machines allow for easy upgrades to software or hardware. Upgrades improve features like separation efficiency and compatibility with different LCD models.