All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(91492 products available)

A lathe, milling, and drilling machine combo is often called a lathe-mill drill combo. This tool is used in the metal and woodworking industries. The lathe's primary function is to spin the workpiece while cutting tools are fed into the piece. The milling machine, on the other hand, has rotating cutting tools that move across the workpiece to create a desired shape. Lastly, the drill machine makes holes into the workpiece.

There are 6 main types of lathes:

Similarly, the drills also have various types. However, all drilling machines perform the same function, which is to make holes in a workpiece. They differ in design and application. Here are some of the most common types:

There are also different types of milling machines:

The specification of a lathe drilling and milling machine is crucial, as it gives potential buyers information about the capabilities and limitations of the machines.

Spindle Speed:

The lathe's spindle speed is the rate at which the spindle rotates. It is measured in revolutions per minute (RPM). The combination of a high spindle speed and a variable-speed motor allows for efficient and precise material removal. As a result, users can change the spindle speed to suit their needs.

Spindle Taper:

The spindle taper is a conical-shaped recess located inside the spindle. It is used for mounting tools onto the lathe. Since there are many types of spindle tapers available, each one is designed for a specific purpose, users can choose the one that meets their needs.

Table Size:

The milling machine's table size is the working surface area available for holding workpieces and tools. A larger table size offers more space for handling larger workpieces, while a smaller table size is designed for more precise machining.

Table Travel:

Table travel refers to the maximum distance the table can move in different directions. This feature determines the size of the workpiece that can fit on the machine and the level of precision that can be achieved.

Drill Chuck Size:

The drill chuck size determines the diameter of the drill bits that can be securely held in the machine's drill spindle. A larger drill chuck size allows for the use of larger drill bits, which makes it suitable for heavy-duty drilling operations.

Toolholder Type:

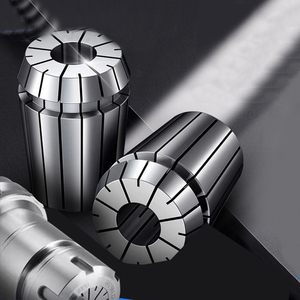

Toolholder type refers to the kind of mechanism used to hold tools in the lathe, milling machine, or both. Common types of toolholders include collet chucks and quick-change tool holders. The toolholder type affects the precision of the tool alignment and the speed of tool changes.

Maintaining a lathe milling and drilling machine combo for optimal performance is as important as its specification. Here are some maintenance tips:

When buying lathe milling and drilling machine combos, it’s prudent to understand the key components that affect their suitability for specific tasks. Here are some of the factors to consider:

Work capacity

Determine the size of the projects to be done. Larger combinations have higher work capacity, which can manage larger workpieces, while smaller ones are suitable for smaller tasks.

Power

The motor power of the machines is considered. Higher powered machines drive through tougher materials without breaking down.

Precision

Consider the tolerance levels and the ability of the machines to perform tasks that require accuracy and consistency.

Material

Combos made from strong materials last longer and provide smooth operations. Common materials include cast iron and steel.

Features

Various features improve functionality, such as variable speed settings, digital readouts, and safety features like emergency stops. Buyers should evaluate these features based on the intended use of the machine.

Mobility

If the machines need to be moved to different locations, consider their weight and whether they have features that facilitate transportation, such as handles or wheels.

With the right tools and knowledge, DIYers can maintain and even fix their lathe, milling, and drilling machine combos. Here are some general guidelines:

Maintenance

Regular maintenance is critical for the longevity and optimal performance of the lathe, milling, and drilling machine combo. Some maintenance practices include:

1. Cleaning: After every use, the combo should be cleaned to remove dust, chips, and debris. Cleaning can be done using a brush and a damp cloth. Users should also clean the T-slots and tables of the milling machine to avoid rusting and damage to the machines.

2. Oil lubrication: Moving parts of the combination machine should be lubricated with the recommended oil. This reduces friction and prevents wear and tear. Parts that need regular lubrication include the lead screw, tail stock, drilling machine spindle, and milling machine knee.

3. Checking V-Belts and Pulleys: Users should regularly check the V-belts and pulleys for signs of wear, cracking, or stretching. Loose or damaged V-belts should be replaced, and proper tension should be adjusted.

4. Tool Maintenance: Users should maintain tools like lathe chisels, drill bits, and milling cutters in good condition. This can be achieved by regularly sharpening them and replacing them when worn out.

Repairs

The following are some DIY tips for fixing common problems:

1. If the lathe has less tension on the bed ways or the carriage is moving freely, the tension can be adjusted using the user manual.

2. Misalignment of the drill spindle can be rectified by realigning it to the recommended position as per the user manual.

3. Loose or worn-out bearings can be replaced by following the steps outlined in the user manual.

4. If the milling machine's table is not moving smoothly, users should lubricate the guide ways and check for any obstructions or damage.

5. If the lathe chuck is not gripping workpieces securely, users should check and tighten the jaws and inspect the chuck for wear or damage.

Q1: Are lathe milling and drilling machine combos easy to maintain?

A1: Yes, they are easy to maintain. Regular maintenance tasks are typically straightforward and can be performed by operators with basic mechanical skills.

Q2: Can these machines handle hard materials?

A2: The combo machines have limitations when working on very hard or tough materials. Users may need to perform more complex operations on softer materials.

Q3: What is the advantage of having a lathe milling and drilling machine combo?

A3: The advantage of having a lathe milling and drilling machine combo is that it saves space and reduces costs while providing versatile machining capabilities.