All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(105550 products available)

Laser sources come in different types. It is vital to understand this as buyers start operational equipment.

A solid-state laser uses a solid gain medium to amplify light. Users then obtain a laser by adding energy to the medium through electrical discharge or another light source. These lasers produce high energy and are very powerful and durable.

Common laser types in this category include the Nd:YAG laser. Nd:YAG lasers are prevalent in industrial settings. This occurs due to their efficiency in metal cutting or and welding. Also, they have applications in medicine for surgical procedures. Moreover, they are used in dentistry.

Gas lasers generate laser light by exciting gas molecules. For instance, a carbon dioxide laser is one of the most popular. It has a CO2 gas mixture that produces infrared light.

In industrial settings, CO2 lasers are effective. They mainly help in cutting and engraving a variety of materials. It also includes plastics, metals, and wood. These lasers are favored due to their high output power and ability to achieve precision in their work.

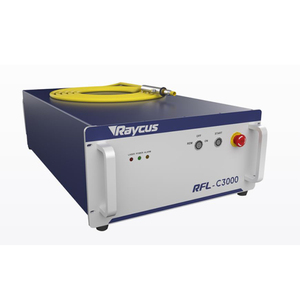

This type uses optical fibers as a gain medium. They are doped with rare elements such as neodymium or ytterbium. Fiber lasers are compact and efficient, offering high beam quality.

The lasers come in handy in metal processing. This includes tasks like cutting and welding in manufacturing environments. Moreover, the lasers are popular in telecommunications, which makes them versatile.

Also known as laser diodes, these lasers utilize semiconductor materials to produce laser light. They offer flexibility in design and are modestly powered. So, this makes the lasers ideal for diverse applications. These include in electronics and telecommunications systems for data transmission.

In industrial settings, laser diodes are critical in automation processes. They are particularly useful for marking and soldering tasks. The wide use in electronic devices contributes to their importance.

Laser sources have multiple features. This is beneficial as businesses consider stocking diverse operational equipment.

Each laser type has a specific wavelength. This affects its application and efficiency. A fiber laser, for instance, has a shorter wavelength than a CO2 laser. It provides better absorption in metals.

The gradient allows for more precise cuts in stainless steel, aluminum, and other hard metals. Conversely, CO2 lasers, with longer wavelengths, excel in cutting thicker materials like acrylic and wood.

Output power determines the laser's effectiveness in a certain task. Higher output power often equals greater cutting and engraving efficiency.

For example, a CO2 laser with an output power of 150 watts can efficiently cut thick wood sheets. On the flip side, an Nd:YAG laser with higher power is better suited for metalwork requiring deep penetration.

Lasers with good beam quality maintain their focus and energy over long distances. Good beam quality means the laser does not lose its intensity as it travels. This is important for long-distance applications, such as laser welding.

Additionally, fiber lasers are renowned for their exceptional beam quality. They are effective in creating fine, accurate cuts in various materials. Poor beam quality makes it hard to achieve a clean cut or a precise engraving.

The efficiency of laser sources directly impacts operating costs. An efficient laser source converts more energy into the laser beam. For example, CO2 lasers have lower energy conversion rates than fiber and solid-state lasers.

Thus, they require more electricity to operate. In contrast, fiber lasers are highly efficient. They require minimal energy, hence lowering operational costs.

Laser sources, such as CO2 and solid-state lasers, use water or air to cool down. Proficient cooling systems maintain optimal performance while minimizing interruptions. Water-cooled systems are efficient at maintaining the temperature of high-output lasers.

They are particularly useful for heavy industrial processes. On the flip side, air-cooled systems are less effective but offer easier maintenance.

Laser sources have a high commercial value. In addition, the business applications promote the product’s statistical relevance.

Lasers are essential in the manufacturing sector. They are widely used for metal cutting, welding, and engraving. Due to precision and speed, laser sources improve efficiency and product quality.

Therefore, businesses use laser cutting machines to create intricate designs in materials like steel and aluminum. They also reduce waste and minimize the need for manual labor.

Commercially, laser sources treat various medical conditions. For instance, Nd:YAG lasers treat vascular lesions and perform intraocular procedures. Moreover, CO2 lasers conduct precise surgical cuts in dermatology. The treatments offer less invasiveness compared to traditional methods.

It also results in reduced recovery times. Their accuracy makes lasers a critical tool in vision correction surgeries and other health procedures.

In defense systems, lasers are used for range finding and target illumination. This has led to an improved accuracy and safety of operations. Also, laser sources conduct non-destructive testing to analyze aircraft components.

This helps identify potential defects without damaging the components. That allows manufacturers to ensure safety and high performance. The use of lasers in these critical applications provides commercial value through cost savings. This is alongside improvements in efficiency and effectiveness.

Laser sources, particularly fiber lasers, are integral to the telecommunications industry. They enable high-speed data transmission through fiber optic cables. Optic fibers cover long distances with minimal signal loss or degradation. This makes them efficient and effective for long-distance communication.

For example, semiconductor lasers transmit data in 5G networks. The wide application of lasers in broadband services has increased demand for advanced laser technologies. They are vital in supporting global communication networks.

Several factors influence the decision of buyers when choosing laser sources. Below are these factors.

The operating needs of a business determine the type of laser it needs. For example, a company that needs to cut metal sheets will benefit from a laser with high power and precision. Such a laser source includes a fiber or Nd:YAG laser.

A business that needs to cut wood or acrylic laser works well with a CO2 laser. Moreover, companies that carry out detailing operations may opt for a semiconductor laser. It offers precision in small-scale operations.

When deciding on the laser source, businesses need to factor in the initial and ongoing costs. These include maintenance, power consumption, and any associated operational costs. Often, CO2 lasers have a lower acquisition cost than Nd:YAG or fiber lasers.

But, CO2 lasers have higher power consumption, which increases operational costs. In contrast, fiber lasers usually have high initial costs due to advanced technology. However, they have low operating costs because they consume less power.

Durability is key, especially in high-demand commercial environments. Semiconductor lasers are preferred for their durability and low maintenance. In industrial environments, solid-state lasers, like Nd:YAG, are highly robust and endure intense operations.

Conversely, CO2 lasers are slightly more sensitive due to their gas medium. They require more frequent maintenance, which affects their overall durability.

Buyers need to factor in how easily the laser source is stored and transported when making a choice. Since most laser sources, like fiber lasers, are compact. Businesses with limited space have an easy time integrating these lasers into their operations. This efficiency takes up less space.

On the other hand, CO2 and solid-state lasers can be large and cumbersome. Such lasers are difficult to transport and set up in different locations. Hence, they are ideal for stationary operations.

A1: Laser sources are compatible with many materials. Most laser cutting machines work with metals. They include stainless steel, aluminum, and brass.

Laser sources also work with non-metals, such as wood. Wood is ideal for CO2 and fiber lasers, while acrylic is easily cut by CO2 lasers. Other materials the lasers work with are leather, glass, and fabric.

A2: Yes, laser sources need maintenance to function well and effectively. The good news is they require less care than traditional cutting tools. Since laser sources do not have blades or mechanical parts, they need less day-to-day maintenance.

However, depending on the laser type, some need to be cleaned more often. For instance, CO2 lasers need the lens cleaned frequently because dust can blur the beam. On the other hand, fiber lasers have lenses that need less cleaning.

A3: The laser source businesses choose greatly depends on their laser requirements. For instance, laser engraving small pieces of metal works best with a fiber laser. This laser provides great precision. On the other hand, a CO2 laser is ideal for larger jobs.

A4: Generally, the higher the laser power, the more effective it will be for large or thick materials. For example, a 1500-watt CO2 laser can cut thick acrylic. It also can handle large metal sheets with ease when cutting with laser.

Laser sources with lower power require more passes to cut through thick materials. This makes them slower and less effective in large projects.

A5: There are safety precautions that users need to follow to ensure their safety. Hence, laser cutting machines have safety glasses that reduce users’ laser exposure. It protects its users from the risk of eye injury.

Laser engravers also have enclosures that keep harmful fumes and smoke contained during operation. This fume reduction minimizes potential harm to the internal organs.