All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(121055 products available)

Laser hardening machines come in various types, each suitable for specific industrial applications. The choice of which laser hardening machine to use can take into consideration factors like the material being treated, the desired hardness depth, and the production volume.

These laser hardening machines are equipped with high-powered lasers, while typically suitable for large-scale production, don't usually have very delicate components. Since it can penetrate much deeper than other types of machines, it is often used in industries that need to strengthen their machine components, like in the automotive or aerospace industries.

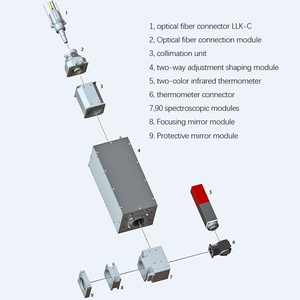

Fiber lasers are known for their high precision and efficiency. This machine is ideal for small detailed parts. It generates a focused and fine laser beam, which makes it suitable for producing intricate components such as gears, shafts, and other precision mechanical elements.

Portable laser hardening machines provide flexibility for on-site operations. These machines.allow hardening work on big parts that cannot be moved to a factory or easily transported. Construction machinery, marine components, and large industrial parts frequently use these models.

These robotic laser hardening machines combine robotic arms with a laser source for precise hardening on complex surfaces. These machines are centered around a laser equipped with a robotic manipulator, allowing the laser to reach and harden the complicated surface of an industrial item. Because of their high accuracy, these devices are especially appropriate for hardening turbine blades and other items with complex geometry.

Laser hardening has become a preferred method in many industries due to its effectiveness in enhancing material properties. Common applications include hardening cutting tools, dies, and molds in the manufacturing sector. Laser hardening enhances the wear resistance of these tools, leading to longer service life and reduced production costs for manufacturers.

In the automotive industry, laser hardening is employed to strengthen components such as gears, shafts, and cam profiless. These parts endure heavy loads and constant wear, making enhanced surface hardness crucial for durability. Aerospace applications leverage laser hardening to treat critical components like landing gear, turbine blades, and structural parts. In these high-stress environments,耐磨性 and fatigue resistance are essential.

Marine and construction industries also benefit from laser hardening. Components exposed to corrosive environments and heavy loads, such as propellers and hydraulic cylinders, undergo laser hardening to extend service life. Additionally, in the energy sector, laser hardening is used on components like valves and pumps in oil and gas extraction, where high wear resistance is mandatory.

The machine's ability to selectively harden surfaces while maintaining the core properties of the material makes it particularly valuable in sectors requiring high precision and durability. Beyond extending product lifespans, laser hardening reduces downtime for replacements and repairs, translating into significant cost savings for businesses with laser hardening machines. As industries continue to prioritize efficiency and sustainability, the increasing adoption of laser hardening technology will be inevitable.

In industrial settings, laser hardening machines must consistently endure and perform optimally under heavy workloads and critical operating conditions to ensure the successful treatment of various components.

Laser hardening machines are built to last. They use very powerful lasers to harden the surface of metals and make them very strong; these lasers produce a lot of heat. To prevent damage from this heat, laser hardening machines have cooling systems that quickly cool down hot parts.

Many industrial pieces of equipment do hard jobs, so a laser hardening machine must withstand all this. These machines must be protected from dust, moisture, and chemicals in the factory. They do this by sealing or coating sensitive components like electrical circuits.

Large laser hardening machines need to keep stable while working on heavy metal items. High-precision machines have flexible parts that can bend to reach their tight laser beams. Strong frames are used to stabilize all machines, including designs that dampen vibrations during the hardening process.

Conversely, the materials used in constructing these machines are critical in determining their efficiency and longevity. Laser hardening machines often utilize high-strength steel alloys in their construction. These steel alloys not only provide structural rigidity to support high-power lasers but also resist the immense heat generated during the hardening process.

Apart from steel alloys, lightweight materials like aluminum are used in parts of these machines. Aluminum reduces the overall weight of portable laser hardeners, making them easier to operate and transport. Despite its lower density, aluminum has good thermal resistance, which helps to prevent heat damage during operation.

Another important material found in laser hardening machines is copper. Copper is regularly used in laser systems because it conducts heat and electricity better than any other metal. It helps keep laser focusing elements cool and functional. In some situations, copper is also used inside components that direct the laser beam to maintain optimum performance.

Choosing the right laser hardening machine involves careful consideration of several factors.

A1: Large and automobile industries like aerospace, automotive, and heavy manufacturing are the most frequent users of this laser hardening service. These industries routinely face the need to enhance durability and wear resistance in metal components.

A2: Steel alloys are the foremost materials used in laser hardening machinery. This is due to their advantages of strength, corrosion resistance, and heat tolerance. Other commonly used metals include aluminum, known for its lightness and strength; and tool steel, which provides superior hardness for cutting and molding tools.

A3: Laser hardening has clear advantages over more conventional techniques like induction or flame hardening. For example, laser hardening's energy efficiency and precision stand out. Laser hardening also avoids the stresses that come with conventional hardening. It also improves component life by reducing distortion and only affecting the surface layer.

A4: Yes, regular service is necessary to maintain the efficiency and longevity of the devices. Regularly cleaning the laser components, checking the cooling system, and updating software are frequent maintenance operations. These activities assist sustain product quality while decreasing machine breakdowns.