(693 products available)

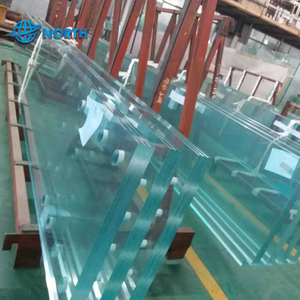

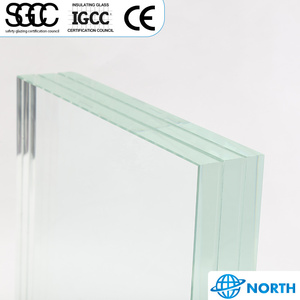

Laminated glass PVB interlayer is layered in between ordinary or tempered glass, which is bonded to form a laminated glass. This interlayer comes in different types, which are as follows:

Standard PVB interlayer:

The standard PVB interlayer offers excellent clarity and adhesion. It has become the most popular choice for laminated glass in residential and commercial applications. This standard interlayer provides safety, UV protection, and noise reduction. It is suitable for use in areas where human traffic is high.

Clear PVB interlayer:

The clear PVB interlayer is widely used when a transparent appearance is needed. It enhances the aesthetic value of any application. This interlayer provides additional safety and UV protection while allowing maximum light transmission. It is suitable for use in architectural projects where clarity is paramount.

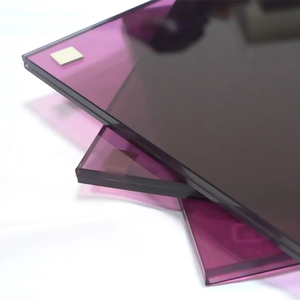

Colored PVB interlayer:

The colored PVB interlayer is designed to add a pop of color to laminated glass. It comes in various colors, including blue, green, gray, and bronze. This interlayer is used to create a unique visual impact in architectural design. It can be used in privacy glass applications to achieve the desired level of opacity.

Frosted PVB interlayer:

The frosted PVB interlayer is textured to create a translucent effect. This helps to diffuse light and provide privacy. It is commonly used in bathroom windows, shower enclosures, and partition walls. The frosted interlayer adds a touch of elegance and sophistication to any space.

Acoustic PVB interlayer:

The Acoustic PVB interlayer is specifically designed to reduce noise transmission. It is laminated with glass to create soundproof or sound-insulating windows. This interlayer is ideal for use in urban areas or locations near airports where noise reduction is critical.

Solar Control PVB interlayer:

The solar control PVB interlayer is engineered to minimize solar heat gain. It does this by reducing the amount of UV and infrared radiation that passes through the glass. This helps to improve energy efficiency and occupant comfort. This interlayer is suitable for use in hot climates or buildings with large glass facades.

Tinted PVB interlayer:

The tinted PVB interlayer is infused with color pigments during manufacturing. This creates a subtle tint that can enhance privacy and reduce glare. Common tints include bronze, gray, and green. It is used in both residential and commercial applications where aesthetic and functional benefits are desired.

Laminated glass PVB interlayer serves multiple functions and features. Here are some of them:

Safety and Security

Laminated glass is primarily designed for safety. In case of breakage, the glass fragments stick to the interlayer, thus minimizing the risk of injuries from sharp edges. This feature makes laminated glass a very suitable choice for applications in areas prone to high impact or vandalism.

UV Protection

The interlayer provides UV protection by absorbing harmful ultraviolet radiation. This protects the interior spaces from UV-related damage, such as fading of furniture, flooring, and artwork. UV protection also helps to minimize the heat buildup caused by the sun's rays.

Sound Reduction

Laminated glass offers sound insulation. The PVB interlayer dampens sound waves, thus reducing noise transmission. This feature is very important for creating quiet and peaceful environments, particularly in urban settings where noise pollution is a concern.

Enhanced Optical Clarity

The laminated glass interlayer is designed to improve optical clarity. It minimizes light distortion and glare. This improves the visual comfort and quality of the inside view. Enhanced optical clarity is important for applications in spaces where natural light is a priority.

Improved Aesthetic Flexibility

The interlayer offers aesthetic flexibility. It is available in various degrees of transparency, from clear to frosted. It also comes in different colors and patterns that can be customized to meet specific design requirements. This feature allows architects and designers to create visually striking and functional laminated glass solutions.

Fire Resistance

Laminated glass can be made with special PVB formulations that enhance its fire resistance. The fire-rated laminated glass meets building codes and offers an important level of protection against the spread of flames and smoke. This ensures occupant safety and property in the event of a fire.

Condensation Resistance

The laminated glass interlayer helps in minimizing condensation. It creates a thermal barrier that reduces the temperature difference between the interior and exterior surfaces of the glass. This minimizes the chances of water droplets forming on the glass, thus improving visibility and preventing mold growth.

Laminated glass PVB interlayer is used in various applications where safety, security, and UV protection are essential. Here are some common scenarios where laminated glass is utilized:

Building and Construction:

Laminated glass is commonly used in commercial and residential buildings. It provides safety and security to occupants. It is installed in windows, doors, and skylights. This glass minimizes accidents from UV radiation and falling debris. It protects furniture, flooring, and artwork from damaging UV radiation.

Automotive Industry:

Automotive manufacturers use laminated glass in windshields. It protects passengers from UV radiation, debris, and shrapnel in case of accidents. Laminated glass enhances passenger safety. It reduces the risk of cuts and injuries from broken glass. This glass maintains structural integrity and keeps occupants safe.

Transportation:

Laminated glass is used in the windshields and windows of buses, trains, and airplanes. It protects passengers and crew from UV radiation, debris, and environmental elements. It ensures passenger safety and comfort during transit.

Architectural Applications:

This glass is used for facades, curtain walls, and interior partitions in commercial and institutional buildings. It enhances security and privacy. It offers aesthetic appeal and natural lighting. Laminated glass is suitable for high-traffic areas. It minimizes noise and reduces the transmission of sound waves.

Interior Design:

Laminated glass is used in interior design applications. It is commonly installed in sliding doors, room dividers, and decorative panels. It creates a sense of spaciousness. It allows natural light to flow while maintaining privacy.

Appliances:

Laminated glass is used in the construction of ovens, microwaves, and refrigerators. It protects users from high temperatures and sharp edges. It enhances appliance safety and durability.

Electronics:

Laminated glass is used in smartphones, tablets, and laptop screens. It protects electronic components from impact and scratch damage. It ensures longevity and reliable performance.

Various factors should be considered when selecting the appropriate interlayer for laminated glass. It is important to note that the choices available are numerous and cater to specific needs and applications. Some of the factors to consider when choosing an interlayer include:

Safety and Security

When prioritizing safety and security, choose interlayers with high impact resistance, such as clear PVB interlayer. This option is suitable for high-traffic areas and applications in prone environments to breakages. Consider using a PVB interlayer with a higher thickness, as this provides enhanced protection against forced entry.

Sound Dampening

If noise reduction is a major concern, select glass interlayers specifically designed for acoustic performance. These PVB interlayers are usually called acoustic PVB interlayer. They offer enhanced sound attenuation by reducing the transmission of noise through the glass.

Climate and Environmental Factors

When choosing laminated glass for locations with extreme weather conditions, opt for interlayers with lower moisture permeability, such as PVB interlayers. These interlayers offer protection against fogging and ensure long-term optical clarity. For tropical climates, consider using an SGP interlayer, as it offers enhanced stability and minimizes the risk of mold growth.

UV Protection and Glare Control

When UV protection and glare control are a major concern, select tinted or laminated glass with special coatings. These glass types block a significant amount of harmful UV radiation and reduce glare. Consider combining laminated glasses with shades or blinds for optimum glare control.

Aesthetic Considerations

When aesthetics are a major concern, choose interlayers that enhance the visual appeal of the glass. Options worth considering include decorative PVB interlayer, which incorporates patterns or colors. Another option is the opacified interlayer, which offers privacy while allowing natural light to pass through.

Regulatory and Building Code Requirements

Consult local building codes and regulations to determine specific requirements for laminated glass in particular applications. Consider factors such as fire safety, energy efficiency, and structural integrity. Ensure the selected laminated glass meets or exceeds the minimum mandated by local authorities.

Q1: What is the laminated glass PVB interlayer?

A1: A laminated glass PVB interlayer is a type of interlayer used in laminated glass that consists of polyvinyl butyral (PVB). It acts as a bonding layer between two or more panes of glass, creating laminated glass. This laminated glass offers enhanced security, UV filtration, and sound insulation.

Q2: What are the applications of laminated glass?

A2: Laminated glass is widely used in various applications, including commercial and residential buildings, automotive windows, skylights, glass doors and railings, museums, and art galleries. It is also used in high-security areas, bullet-resistant glass, and privacy glass.

Q3: What are the benefits of laminated glass?

A3: Laminated glass provides numerous benefits, including improved security, noise reduction, UV protection, and structural integrity. In the event of breakage, the glass remains intact, reducing the risk of injury. It also blocks a significant portion of harmful UV rays, protecting interior furnishings.

Q4: How is laminated glass made?

A4: Laminated glass is made by sandwiching a layer of PVB interlayer between two or more panes of glass. The assembly is then subjected to heat and pressure in an autoclave, causing the PVB to bond firmly with the glass. This process creates strong and durable laminated glass.

Q5: What is the difference between tempered and laminated glass?

A5: The primary difference lies in their strength and safety characteristics. Laminated glass consists of PVB interlayer and standard float glass, while tempered glass is produced through a high-heat strengthening process. Laminated glass excels in security and UV protection, whereas tempered glass is stronger and safer when shattered.