Introduction to Lab Equipment for Paint

Lab equipment for paint play a crucial role in the formulation, testing, and quality assurance of paints and coatings. In a world where aesthetics and functionality are paramount, the right lab tools can enhance the capability of research and development teams to innovate and refine their products. Specialized instruments are essential for ensuring that paints not only look appealing but also adhere to standards of durability, safety, and environmental impact.

Types of Lab Equipment for Paint

There is a wide array of lab equipment tailored for paint-related tasks, each designed to fulfill specific functions in the production process. Understanding these types can empower manufacturers to select the most suitable tools for their needs.

- Viscometers: Used to measure the viscosity of paint, ensuring a consistent texture and flow for optimal application.

- Spectrophotometers: Essential for color analysis, allowing manufacturers to match and replicate colors accurately.

- Heat and Cold Stability Testers: Evaluate how paints behave under different temperature conditions, which is vital for applications in varying climates.

- pH Meters: Critical for ensuring appropriate acidity or alkalinity in formulations, which affects performance and longevity.

- Adhesion Testers: Assess the bonding strength of paint to various surfaces, ensuring reliability and durability.

Function and Feature of Lab Equipment for Paint

The functionality of lab equipment for paint lies in its ability to accurately assess various properties critical to paint formulations. Here are some remarkable features:

- Precision Measurement: Most equipment is designed to provide highly accurate measurements, which is vital for quality control.

- User-Friendly Interfaces: Many devices come with intuitive interfaces and software options, simplifying data acquisition and analysis.

- Durability: Constructed with high-quality materials to withstand frequent use in a dynamic lab environment.

- Portability: Some equipment is lightweight and portable, enabling easy transport between different locations, facilitating on-the-go testing.

- Integration Capability: Various devices can connect with other lab systems, allowing seamless data uploading and collaboration.

Applications of Lab Equipment for Paint

The applications of lab equipment for paint are numerous, spanning across various sectors and industries, each benefitting from advanced testing and formulation techniques. Here are key applications:

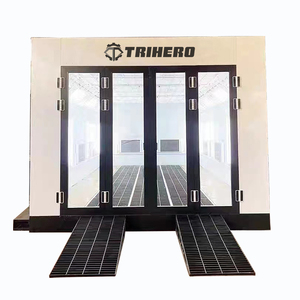

- Automotive Industry: Testing paint durability and finish quality to ensure vehicles can withstand environmental wear and tear.

- Construction: Evaluating exterior paints for long-lasting performance and resistance to weather conditions.

- Manufacturing: Used in the production of industrial coatings that require stringent performance specifications.

- Art Restoration: Assists in matching historical colors and formulations accurately for preservation projects.

- Research and Development: Essential in laboratories focusing on innovative paint formulations that push the boundaries of technology and sustainability.