All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(676 products available)

Knurling bushes serve as supporting equipment during the knurling process by providing suitable places for the knurling rollers in machines. Several types of knurling bushes are used in various businesses based on their desired characteristics and applications.

Here are the most common types of knurling bushes:

Solid bushes

Because of their robust structure, solid knurling bushes are appropriate for heavy-duty applications. Their strength increases the amount of knurling made by the machine; thus, they work well in high production. Most industries where these types are frequently used include automobiles, metallurgy, and appliance manufacturing.

Bronze bushes

Bronze, known for its excellent wear-resistant properties, makes a great choice for knurling bushes. Because of this, they are frequently used in applications where there is a low chance of oil or where self-lubrication is required. Bronze bushes can be found in low- to medium-power transmission systems, small mechanical devices, and machines that are operated in dust-prone environments.

Ball bushes

Ball bushes are used whenever there is a need for low-friction movement. In such an application, a smaller ball inserted between the two larger rings permits the bushes to rotate or slide smoothly. This property reduces wear and water-energy transfer to other components in the system, making them ideal for high-precision manufacturing machines, conveyor systems, and robotics.

Sliding bushes

Sliding bushes permit movement along a specific path so that linear motion can be evenly distributed in the system. These types of bushes are used in machinery systems in which components have to shift or adjust with minimal friction, such as in guidance or support systems in manufacturing equipment, conveyors, and industrial robots.

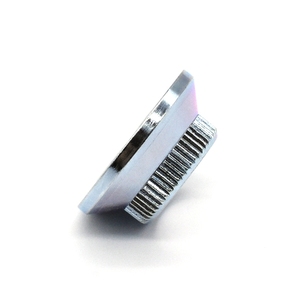

Flanged bushes

Flanged bushes are distinguished from other bronze or ball bushes by the flange, which is a protruding rim on the bush. This feature helps with the correct positioning and preventing the bush from shifting. Mostly used in combination with sliding or ball bushes, flanged bushes find their application in production belt equipment, rotating devices, and engineering systems that require precise location and stability.

The materials used to make Knurling bushes are selected based on the properties available to them and the purpose to which the product is put. Knurling bushes come in different types of materials, including metal, polymers, or composites, each with advantages for certain industrial uses. Below are the materials used and the various functions of a knurling bush:

Metallic bushes

Metal bushes are produced from steel to bear the maximum amount of mechanical wear from the knurls. Steel bushes offer high tensile strength, hardness, and a long-life span. Such properties make them desirable for use in machine tool industry roller coasters, metal-forming equipment, and high-demand applications. Bronze bushes, as discussed, also belong to the metal category. They are self-lubricating and, therefore, suitable for dry lubrication and low-friction systems.

Polymer-based bushes

Due to their wear-resistant and lightweight characteristics, polymer-based knurling bushes are preferred in several industries. Polymers are affordable and can be used in applications that require a non-conductive or corrosion-resistant substance. In the automotive, electrical, and plastics processing industries, these bushes are commonly used for moderate-load and low-friction surfaces.

Composite Material bushes

Composite material bushes combine metallic and non-metallic properties to yield the performance benefits of both materials. These bushes are of metal-fiber composite material; thus, they have good wear and tear resistance and a low coefficient of friction. They are used primarily under moderate mechanical loads and severe conditions to assist in the dampening of shocks and vibrations. Found in aerospace, defense, and high-end machinery, these bushes are highly prized for their durability and lightweight properties.

Function of knurling bushes

Knurling bushes provide a supporting structure that holds the knurling rollers in place, ensuring that the knurling process is effective and that the load is appropriately transmitted through the system. The primary functions of knurling bushes are as follows: first, they ensure the stability of knurling by positioning the rollers and enabling accurate patterns on the material; second, they reduce friction and are, therefore, great for load distribution, thus protecting machine parts from premature wear, thirdly; through this load distribution, strain concentration is reduced, and the longer mechanical durability is achieved.

Material transformation processes

Knurling bushes are common in metalworking and other reforming processes. They hold and shape materials such as metal sheets and wires, so when knurled, the desired textured surface is achieved. This texturing provides better gripping, bonding, and surface characteristics for followup processes like coating, painting, and welding. Knurling bushes offer a critical advantage involved in enhancing the effectiveness of the subsequent processing stages in the material manipulation fields.

Surface Texturing in Manufacturing

The knurling bush is critical in the manufacturing process, especially when making textured surfaces on parts for mechanical use. The texture is useful on handles, grips, or mechanical parts, giving them the required friction and better use. Knurling provides aesthetic appeal and functional purposes, like slippage reduction in parts that are joined together. In industries such as automotive, consumer electronics, and appliances, correctly implemented knurling is vital in fulfilling product design and performance specifications.

Tire Retread Industry

Tire retreading is the process of renewing worn-out tires by replacing the tread. Knurling bushes are used here to create patterns on the retread rubber; thus, they affect the tires’ grip and handling performance when retreaded. The degree of wear that an existing tire can take before it needs complete replacement is influenced by how deep or well-defined the knurls on the retread patterns are. Knurling bushes produce more efficient and longer-lasting retreads in the tire knurling machine.

Texturing Protective Coatings

Beyond the industrial application, Knurling bushes are useful for textured micrometric protective coatings over materials such as metals and plastics, which will enhance their resistance to wear, corrosion, and thermal shocks. The textures can improve grip on surfaces and be used in engineering applications such as aerospace and defense. These sectors require coatings that are effective in protecting against environmental degradation while maintaining the characteristics of the underlying material.

Printing and Engraving

In the fields of printing and engraving, knurling bushes help produce patterns or textures on printing plates or cylinders. Such textures influence the quality and characters of the prints, like the depth of ink and shading. Knurling bushes are responsible for maintenance and cleanliness in knurling machines in these processes, which ensures possible precise and repeatable results. In commercial printing and packaging industries, this application is most common, and minor variations can significantly impact print quality and aesthetics.

For Knurling bushes to perform effectively and for the durability of the machine, there is usually a need to be very critical and precise when selecting the right materials. Below are several factors to consider:

Material compatibility

The operating characteristics of materials for which knurling bushes should be compatible to ensure efficient performance are known. Steel bushes, for example, are suitable for hard-wearing applications, while bronze is more suited for self-lubricating, low-friction environments. The choice of material can also be dependent on whether the application environment demands corrosion resistance or electrical insulation, as in the case of metal and polymer materials.

Load capacity

Knurling bushes come in varying degrees of load-bearing capacity; therefore, the selection should match the bush's mechanical load-bearing ability. A high load-bearing capacity in a frictionless or low-friction contact application means lower wear rates for the bush and associated machine components. For example, a knurling bush for the aerospace industry should have a low-friction surface to improve performance and reduce fatigue over time.

Friction and lubrication properties

There is a need to consider bush friction and lubrication properties. Some bushes, such as those made of bronze or certain polymers, have a fairly good lube coefficient and lube themselves, suitable for low-lubrication environments. High-friction bushes require regular lubrication to reduce wear; thus, maintenance is frequent and potentially costly. The knurling bush selection is imperative for reducing the frictional surface contact and giving rise to smooth operational characteristics, especially in applications such as electrical motors or robotic actuators. This consideration helps avoid heating and wear and increases the life of adjacent components.

Thermal resistance

Some applications result in excessive heat generation; therefore, Knurling bushes need to have thermal resistance. Certain metals and some high-performance polymers are able to resist thermal degradation, which makes them ideal for use in high temperatures. A good thermal barrier in a machine tool or aerospace component is vital in the selection of a bush to ensure its stability during extreme operating conditions, reducing thermal deformation and breakdown.

Ease of installation and fit

The selection criterion involves how easily the knurling bush can be fitted within its designated space with no play and appropriate clearance. The operational efficiency of the machine depends on whether there is easy installation without misalignment and play. Knurling bushes that have a standardized dimension are ideal for retrofitting in any existing machines, while custom-made bushes are used in very specific applications. Accurate fitting can enhance performance, reduce wear, and eliminate vibrations.

A1: The material used in the knurling bush determines its resistance to wear, thermal shock, lubrication requirement, and operating lifespan. For example, bronze bushes are self-lubricating and, therefore, appropriate for dry conditions, while steel bushes are suitable for heavy-duty applications because of their strength.

A2: Industries such as aerospace, machine tools, and robotics have high mechanical loads and, therefore, require Knurling bushes that can withstand extreme pressure without warping or wearing out. In these industries, failure could lead to dangerous conditions, so the materials used must keep the bushes stable.

A3: In tire retreading, knurling bushes create patterns on retread rubber. These patterns dictate the tire's grip, water evacuation, and overall performance. Knurling bushes ensure that tires give the best possible traction and durability after retreading.

A4: Yes, Knurling bushes, particularly those made of self-lubricating materials such as bronze or specific polymers, can reduce maintenance needs. These bushes wear evenly and efficiently, lowering the need for frequent checks and lubrication, thus saving time and resources for a certain industry.

A5: Knurling bushes secure the rollers used to create specific textures on mechanical parts during the surface texturing process. These textures improve the grip and functionality of parts in applications where slippage is an issue, for example, in automotive or consumer electronics.