All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(30 products available)

Kiln seasoning timber is a method of drying green wood in a controlled environment so that it can be used for various purposes. There are different kinds of kiln seasoning timber based on heating methods and drying processes. They can be classified into two broad categories.

Classification based on heating methods:

This classification is based on the heat source for the drying process.

Classification can be done based on the heat source used to dry the wood.

The first one is an electric kiln. It uses electricity to heat air in a chamber to dry timber. This type of kiln is suitable for small-scale operations or where there is limited space.

Gas kilns are another option. They burn gas in a burner to produce hot air for drying timber. It is efficient for large-scale operations.

Steam kilns dry wood using steam. They generate steam and condense it into water to release heat for drying timber.

Oil-fired kilns burn fuel oil to heat air for drying timber. They are economical and efficient for large-scale operations.

Wood-fired kilns are also available. They use wood as fuel to generate heat for drying timber. This is suitable for remote areas with abundant wood resources.

Electric vacuum kilns combine electricity with vacuum technology to dry wood quickly and efficiently.

Dehumidification kilns use external energy sources to remove moisture from the air, thus drying the timber.

Classification based on drying processes:

This classification is based on the drying process of the wood.

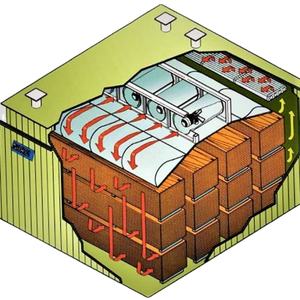

In continuous kilns, a constant supply of timber is fed into the kiln while another batch is removed at the same time. This ensures continuous operation and maximum efficiency.

Batch kilns operate by processing one batch at a time. A certain amount of timber is loaded, dried, and then unloaded.

Track kilns have a moving track system that allows timber to be gradually dried as it moves through different sections of the kiln.

Cart kilns use stationary dryers, and carts are pushed into and out of the furnace. They are cost-effective and simple.

Chamber kilns dry timber in separate chambers, each with its heating and ventilation controls. Different batches can be dried simultaneously.

Tunnel kilns have a long, enclosed space where timber is placed on trolleys that move continuously through the heated section.

Conveyor belt kilns use conveyor belts to transport timber from one end of the kiln to another.

Ring kilns are circular and revolve around a central axis, allowing for even heat distribution and efficient drying.

Rotary drum kilns use a rotating drum to mix and move material through hot gases.

Vents:

These are small openings in the kiln that allow steam and moisture to escape. Their size and placement are crucial for maintaining the right humidity levels inside the kiln.

Heating elements:

These are parts that provide heat to the kiln, which can be in the form of electric coils, gas burners, or oil-fired burners. The type of heating element affects the efficiency and operating cost of the kiln.

Insulation material:

This keeps the heat inside the kiln and protects the wood from outside temperature fluctuations. Good insulation saves energy and speeds up the drying process.

Humidity control instruments:

These are necessary for monitoring and regulating the moisture content in the air within the kiln. Hygrometers, humidistats, and water pan evaporation methods are common tools used for this purpose.

Temperature control gadgets:

These are devices for measuring and controlling the temperature inside the kiln. Thermometers, thermostats, and temperature recording charts are widely used to ensure that the heat levels are appropriate for drying wood.

Flow regulators:

These are mechanisms that adjust the speed of air movement in the kiln. Dampers, fan speed controllers, and blower switches are typical flow regulators used to achieve uniform drying of timber.

Safety features:

These are essential components that prevent accidents during operation. Smoke detectors, fire extinguishers, and pressure relief valves are standard safety devices used in wooden kilns.

Size and capacity:

This is a design aspect of the kiln that determines how much wood can be dried at once. Small batch kilns have a capacity of 500 kg, while large commercial ones can handle over 100 tonnes per load.

Material used:

This is a design aspect of the kiln that determines the materials used for construction, which can be steel, bricks, or concrete. The choice of material affects durability, maintenance costs, and initial investment cost for the kiln.

Type of kiln:

There are different designs for kiln types, which include steam-heated, solar-powered, and electric wood drying kilns. Each type has its advantages and disadvantages depending on the availability of energy sources, cost of fuel, and environmental considerations.

Furniture making

Furniture makers need wood that is stable and has a consistent moisture content. This ensures that the furniture does not crack or warp over time. For instance, a dining table made from kiln-dried oak will maintain its shape and size for many years, even with the seasonal changes in humidity.

Construction industry

Construction companies use seasoned timber for building homes and other structures. Kiln-dried wood is less likely to attract pests like termites and is also fire-resistant, making it a safer choice for construction. Beams, studs, and trusses made from this kind of wood will last longer and need less maintenance.

Craft and hobby projects

Hobbyists who carve or build with wood prefer kiln-seasoned varieties because they are easier to work with. When making a model airplane or a wooden sculpture, using dried timber means there will be no unexpected changes in the wood that could ruin the project. It is especially important for intricate and detailed work where precision is key.

Musical instruments

Some instruments like guitars and pianos depend on properly dried timber for good sound quality. The wood used in these instruments must have a uniform moisture content so that it can vibrate properly to produce music. A kiln-dried guitar will have a better tone and resonance than one made with undried wood, which may swell or shrink and alter the sound.

Wooden flooring

Flooring manufacturers need wood that will not warp or crack when walked on. Kiln-dried timber is ideal for this purpose as it maintains its shape even with changes in temperature and humidity levels. A hardwood floor made from such wood will be more comfortable and durable over time, requiring less repair work.

Musical instruments crafting

Craftsmen who make musical instruments like guitars, pianos, and violins need kiln-seasoned timber. The drying process enhances the wood's acoustic properties, making instruments sound better. For example, kiln-dried spruce is used for guitar tops because it vibrates well, producing clear tones. This stable wood also allows precise shaping, ensuring quality instruments.

Timber seasoning is crucial for the durability and workability of the wood. Here are some important factors to consider when choosing kiln seasoning timber.

Wood species

Consider choosing wood species that are suitable for the intended purpose. Some wood species are suitable for outdoor use, while others are suitable for furniture making. Ask the supplier for advice on the best wood species for a particular purpose.

Initial moisture content

Choose timber with the appropriate initial moisture content for the intended use. If the timber will be used in a high-humidity environment, choose timber with a higher initial moisture content. If it will be used in a low-humidity environment, choose timber with a lower initial moisture content.

Size and shape of the timber

Choose timber that is properly sized and shaped for the intended use. Kiln drying can cause some deformation of the timber, so selecting timber that is properly sized and shaped is important. Consider the defects that may arise during drying and choose the appropriate seasoning method to mitigate them.

Defects and damages

Check the timber for defects and damages before purchasing it. Some defects, such as knots and cracks, may become more pronounced after drying, so choosing timber with minimal defects is important. Ask the supplier for information on how to identify defects in kiln-dried timber.

Drying rate and temperature

Choose the appropriate drying rate and temperature for the type of timber. Some timber species are sensitive to high temperatures and may be damaged by rapid drying. Select a seasoning method that will dry the timber properly without damaging it.

Energy efficiency

Consider the energy efficiency of the kiln drying process. Some kilns use more energy than others, so choosing a kiln that uses less energy is important. Ask the supplier for information on the energy efficiency of the kiln drying process.

Q1: What is the purpose of kiln seasoning wood?

A1: Kiln seasoning wood reduces the moisture content in the timber and thus prevents it from growing mold or mildew. It also makes the wood less prone to insects and ensures it remains strong and durable.

Q2: How long does kiln seasoning take?

A2: The duration of kiln seasoning depends on the type of wood and the desired moisture content. For softwoods, it may take 1-2 days, and for hardwoods, it can take up to a week.

Q3: What temperature is required for kiln seasoning?

A3: The temperature in the kiln should be between 60 degrees Celsius and 82 degrees Celsius (140-180 degrees Fahrenheit) to kill any insects or larvae.

Q4: Is artificial drying in a kiln safe for all types of wood?

A4: Some woods may be damaged by rapid drying. Therefore, the seasoning process should be adjusted according to the type of timber used.

Q5: What are the advantages of kiln seasoning timber compared to air drying?

A5: Kiln drying is faster than air-drying and gives better control over the final moisture content. It also eliminates pests and reduces the risk of warping or cracking.