All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(30503 products available)

The k10 flat carbide inserts are suitable for turning non-ferrous metals, such as copper, aluminum, and brass. They are also useful for plastic machining. It produces a smooth finish on these materials because of its sharp cutting edge and lower cutting angle. K10 flat carbide insert applications include the following:

They are mainly used on CNC automatic lathes to perform high-speed cutting operations on easily machined workpieces.

K10 inserts are also used on manual lathes for basic cutting and finishing operations on softer metals and plastics.

K10 flat inserts are good for specialized tasks such as grooving, parting, or making a consistent flat surface on cylindrical components.

There are different features of the k10 flat carbide insert, such as:

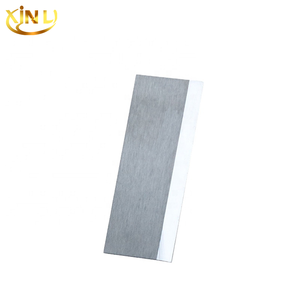

The hardest carbide insert consists of 92%-97% tungsten carbide and 3%-7% cobalt. The former provides hardness, while the latter binds the particles together to give toughness. This makes the inserts heat and wear resistant.

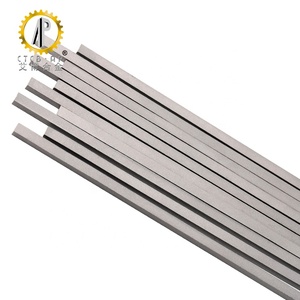

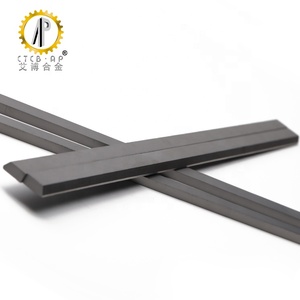

As the name suggests, the k10 insert has a flat shape. It is a square with 0° allowance and 5° relief angle. This geometry is good for producing flat surfaces or machining tasks, requiring a consistent contact edge.

It has a sharp cutting edge that minimizes cutting force and workpiece deformation. This ensures a precise and smooth finish on the cut item.

Many manufacturers of the k10 flat inserts use the metric system when measuring their features. For instance, they state the thickness in millimeters and micrometers, while the radius is in millimeters and sometimes micrometers. This affects the insert's edge.

Even though they have various sizes, most of the k10 flat inserts are produced in standard sizes. This ensures easy compatibility with other tools and machinery. Note that the standard is globally recognized, so they will be the same, regardless of the country where they are produced.

Vardex lathes require k10 inserts to have an MTGNL style. Other machines may also need this style to operate efficiently and produce the desired outcomes.

The flat carbide insert, k10, is used in various fields, and these uses benefit companies. Here are several commercial uses:

Most metalworking industries use the k10 inserts during machining processes to meet the demand for high-precision components. These industries deal with making cut tools, molds, dies, and machining parts, among other items.

These industries manufacture aircraft, which requires a high level of precision and quality. The lathes mostly used in these industries need the k10 inserts to machine aluminum components effectively.

The electronic equipment industry also demands high precision, so they use k10 inserts during machining to produce metal parts in devices like smartphones, computers, and circuit boards.

The medical equipment industry requires high-precision and durable components to produce quality products. So, they use k10 inserts during machining to manufacture medical tools, implants, and devices. The same goes for the automotive industry.

This industry also requires machining inserts, making k10 insert a suitable contender. Businesses here use them to manufacture molds, dies, and other tooling equipment.

The farming equipment industry relies on machining inserts like k10 to make durable and efficient components in their tractors, plows, harrows, and other machines.

Similar to aerospace, the defense industry needs k10 for efficient service. They use these inserts to make components like weapons, vehicles, and defensive systems.

Many machining shops and mechanical repair businesses need k10 inserts to offer their services. Such businesses usually have low budgets, so they go for affordable inserts which, in this case, are K10.

There are several considerations buyers should make when purchasing a k10 carbide insert. Here are these factors:

What the insert will mostly be used for determines the sort of insert to buy. The k10 inserts are suitable for finished machining of soft materials such as brass, aluminum, and plastic. However, they should not be the primary tool for stainless steel.

Buyers must consider the type of lathe they will use the K10 insert with. Different lathes have different insert holders. Companies without insert holders compatible with lathe k10 can make them. This takes a short period. However, it is essential to note that custom insert holders are unsuitable for high-volume production. This is because they are expensive and less durable.

Buyers should look for an insert with good edge strength and toughness. These two properties ensure better resistance to chipping and cracking. They also ensure the inserts can withstand cutting forces. It is better to get inserts with added coatings for additional insulation against wear.

The cutting tool used on the insert should be compatible with the lathe holder. Incompatible tools will lead to poor insert performance and, eventually, poor cuts. when purchasing cutting tools, buyers must look for those compatible with K10 inserts.

Different inserts have various geometries that are suitable for different tasks and materials. Buyers should purchase an insert with an appropriate geometry for their target tasks. For instance, inserts with a sharp cutting edge are ideal for finish cuts. Those with a large corner radius are suitable for heavy cutting, while those with a small corner radius are ideal for rigid materials.

These inserts are mainly used on CNC automatic lathes during high-speed cutting operations. So, they are primarily used on CNC machines. They are also used on some manual lathes.

The most common defect in K10 inserts is chipping. This usually occurs after prolonged use. Regular inspections and proper storage will help as a preventive measure. Using the right cutting tools and techniques will help reduce the chances of chipping.

Yes, K10 inserts can successfully handle many of high manufacturing's normal (not extreme) requirements. This includes producing consistent, quality finishes on specific materials. However, it's crucial to use them within their recommended parameters to avoid wear or damage.

No, they are not. K10 inserts are designed for finishing operations. They excel at delivering smooth, precise cuts on softer materials. However, they aren't suited for heavy cutting. Using them in such tasks could lead to chipping or breakage, so it's essential to match the insert's specifications with the machining requirements.

K10 inserts have several benefits for metalworking businesses. These benefits include the following:

K10 flat inserts can be used on various materials, including aluminum, plastic, and brass. This makes them useful for many clients.

They offer great performance at a reasonable price. This gives them a low cost per machining task. Moreover, their durability extends the inserts' lifespan. This further reduces the cost.

K10 inserts are known for their exceptional durability. Often, they are fabricated with high-quality carbide materials that withstand wear and tear. Also, the sharp cutting edges are designed to prevent chipping. This ensures consistent performance over time. The durability helps businesses to reduce the frequency of insert replacements.

These inserts are manufactured in standard sizes, making them compatible with various lathes and machine tools. This allows easy integration into existing setups, eliminating the need for modifications. Their compatibility also allows businesses to use them across different clients with various machines.

The sharp edge and low cutting angle produce a smooth finish on workpieces. This reduces the need for additional finishing operations. It saves time and labor and increases customer satisfaction by providing high-quality surface finishes.

Difficult workpieces can be finished much faster with K10 inserts, increasing productivity. High-precision components can be produced quickly without compromising quality.

K10 inserts are easily mounted onto existing tools and holders, allowing quick replacement. This saves time during insert changes, enabling clients to maintain efficient production flows.