Understanding Isomerization Catalysts

Isomerization catalysts play a crucial role in the petrochemical industry, significantly enhancing the efficiency of processes by converting precursor molecules into their isomeric forms. These catalysts are essential for improving the quality of fuels and chemicals, making them indispensable in various applications, from fuel refinement to specialty chemical manufacturing.

Types of Isomerization Catalysts

Isomerization catalysts can be classified into different types based on their chemical composition and application. Understanding these types can help in selecting the right catalyst for specific industrial needs.

- Metal-based Catalysts: These typically include noble metals such as platinum and palladium. Their high activity and selectivity make them ideal for processes requiring fast reactions.

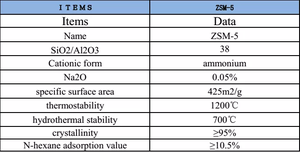

- Acidic Catalysts: Examples include zeolites and solid acids. These catalysts are favored for their ability to facilitate reactions under milder conditions, improving product yield without excessive energy input.

- Hybrid Catalysts: Combining both metal and acidic properties, hybrid catalysts offer a balance of activity and selectivity, making them suitable for various reactions in petrochemical applications.

Applications of Isomerization Catalysts

The range of applications for isomerization catalysts spans multiple sectors, primarily targeting the enhancement of hydrocarbon processing. Their utilization ensures products meet strict regulatory standards while optimizing performance.

- Fuel Production: Isomerization catalysts are pivotal in refining processes to convert straight-chain hydrocarbons into branched forms, resulting in fuels with improved octane ratings.

- Chemical Synthesis: They facilitate the transformation of basic chemicals into more complex isomers, enhancing chemical diversity in pharmaceuticals and agrochemicals.

- Polymer Manufacturing: In the production of specialty polymers, isomerization catalysts help control the molecular structure, which determines the material's properties and performance.

Advantages of Using Isomerization Catalysts

Utilizing isomerization catalysts offers numerous advantages that enhance process efficiencies and product outcomes. These advantages make them integral to modern industrial practices.

- Increased Yield: Isomerization catalysts enable higher conversion rates with minimal by-product formation, ensuring that the maximum amount of resources is transformed into valuable products.

- Energy Efficiency: By facilitating reactions at lower temperatures and pressures, these catalysts reduce energy consumption, contributing to more sustainable production practices.

- Enhanced Product Quality: Catalysts improve the structural characteristics of fuels and chemicals, leading to products that perform better in their respective applications.

- Cost Effectiveness: Improving the efficiency of processing not only lowers operational costs but also prolongs catalyst life, translating to reduced replacement expenses.

![[Richem]ZSM-5 Zeolite/Molecular Sieve / Make Hydrocracking <strong>Catalyst</strong>/VOC Adsorption](http://s.alicdn.com/@sc04/kf/He75cc475e4b34008891359ebf127143cP.jpg_300x300.jpg)

![[Richem]ZSM-5 Zeolite/Molecular Sieve / Make Hydrocracking <strong>Catalyst</strong>/VOC Adsorption](http://s.alicdn.com/@sc04/kf/He0318239b1374c7d8d7b8e3863458563p.jpg_300x300.jpg)

![[Richem]ZSM-5 Zeolite/Molecular Sieve / Make Hydrocracking <strong>Catalyst</strong>/VOC Adsorption](http://s.alicdn.com/@sc04/kf/Hb37168de32c34c62a187922c0db8c276p.jpg_300x300.jpg)

![[Richem]ZSM-5 Zeolite/Molecular Sieve / Make Hydrocracking <strong>Catalyst</strong>/VOC Adsorption](http://s.alicdn.com/@sc04/kf/HTB1LLO0t1SSBuNjy0Flq6zBpVXaz.jpg_300x300.jpg)