All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4420 products available)

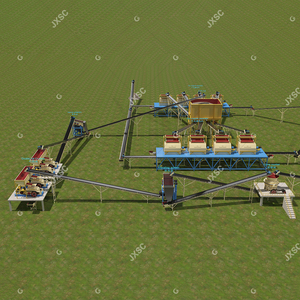

The iron ore processing plant is mainly divided into three parts to process iron ore: crushing, grinding, and iron ore beneficiation process. The main equipment includes the jaw crusher, the ball mill, the magnetic separator, and the vibrating screen. Here are the types of iron ore processing plants in more detail:

The first step in processing iron ore is to prepare the ore by crushing it into small pieces, which are suitable for further processing. The iron ore crusher used in the iron ore processing plant is an iron ore crusher that is designed to reduce large rocks into smaller rocks, gravel, or rock dust. The crushing process is achieved by the use of an impact crusher, a jaw crusher, or a cone crusher.

Crushing and grinding are the two primary comminution processes. The crushing and grinding operations are two essential processes in the iron ore processing plant that are used to release the iron (hematite) and magnetite minerals from the waste rock. Iron ore should be ground to release the mineral from the gangue, then separate the iron minerals from the gangue through various techniques.

The iron ore beneficiation process is the final stage of processing iron ore. The main goal is to achieve a high level of purity of the final product by removing as much of the gangue minerals as possible. Flotation is often used as a beneficiation method to separate valuable minerals and gangue minerals in iron ore. The wet high-intensity magnetic separator is used to separate the magnetic minerals from the non-magnetic minerals. The jigging machine is also used to process various kinds of ores, including iron ore. The iron ore magnetic separator is also an application of magnetic separation equipment that separates magnetic minerals from non-magnetic minerals. The magnetic separator is used to move all the iron ore and other materials to the magnetic field.

There are different types of iron ore processing plants, and they have different applications. The above is a brief analysis of the types of iron ore processing plants.

The specifications of an iron ore processing plant may vary depending on the scale and capacity. Here are some common specifications and maintenance tips to keep it running smoothly.

Iron ore processing plants have different production capacities, and their output is measured in tons per hour. For industrial-scale plants, this figure can go up to several thousand tons per hour. It is important to note that the output capacity of an iron ore processing plant is dependent on various factors like the type and quality of the ore being processed, the processing technique, the plant's design, and its operational efficiency and so on.

Iron ore processing plants consume a massive amount of energy during the entire ore beneficiation process. This includes the energy used to crush and grind the ore, heat and shape it, and power the machinery and equipment used in the iron extraction process. The energy consumption of an iron ore processing plant is usually measured in kilowatt-hours per ton of processed ore (kWh/t). Optimal energy consumption is vital to managing the operational costs and environmental impact of the plant. A few ways to reduce energy consumption in an iron ore processing plant include the use of energy-efficient equipment and machinery, process automation, regular energy audits, and implementation of energy management systems.

Regular maintenance is essential for the smooth operation and longevity of any iron ore processing plant. The plant should be inspected on a regular basis for signs of wear, damage, and potential issues. This involves checking and replacing any worn or damaged parts, lubricating moving components, calibrating equipment, and inspecting the electrical system to ensure proper functioning. Regular maintenance minimizes unexpected breakdowns and ensures the plant runs at optimal capacity. The maintenance schedule should be adhered to strictly to improve equipment efficiency and avoid costly downtime.

Iron ore is the raw material used for making steel and is found in the form of hematite, magnetite, goethite, limonite, or siderite. Iron ore processing plants play a critical role in the mining industry. They are crucial for beneficiating and extracting iron from ore, which is then used to produce steel and other metal products.

Iron ore processing plants are used in various scenarios across different industries.

Some important things to consider when choosing an iron ore processing plant include:

Identify the specific needs of the industry. Consider the required capacity, output size, feed size, types of materials, and the desired final products. This will help in selecting the right sinter plant process with the appropriate screening, crushing, grinding, magnetic separation, and filtering equipment.

Consider the iron ore pellet plant process performance and efficiency. Choose equipment that can handle the anticipated processing volume. Also, ensure that the plant's energy consumption and operating costs are within acceptable levels. This will help maximize the plant's production capacity and profitability.

Choose a reliable manufacturer with a good reputation. Check the manufacturer's track record and customer reviews. Ensure that the manufacturer has a wealth of experience in the design and production of iron ore beneficiation plant. Go for a manufacturer that can provide comprehensive technical support and after-sales service.

Consider the site's layout and environmental conditions when selecting an iron ore processing plant. Make sure the equipment can fit the available space and comply with environmental standards. Also, consider the plant's transportation infrastructure and access to utilities to ensure smooth production operations.

Consider the future needs of the project when selecting an iron ore processing plant. Choose equipment that allows for easy maintenance, upgrades, and expansion. This will help adapt to changing production requirements and technological advances.

Q1: What are the benefits of purchasing an iron ore processing plant?

A1: Owning an iron ore beneficiation plant comes with several benefits. First, the user can control the content and quality of products they get. Secondly, it is a great way to cut down on the costs of raw materials. Simply put, owning a plant can significantly increase the company’s bottom line.

Q2: What is the lifespan of an iron ore processing plant?

A2: The lifespan of an iron ore processing plant may vary depending on the maintenance, usage, and model. Generally, properly maintained plants can serve for over 20 years or more.

Q3: What are the major components of an iron ore processing plant?

A3: An iron ore processing plant has different components. Some of the common ones include the primary crushing system, the processing plant, the screening station, the secondary crusher, and the stockpiles. However, there are other important parts. The parts are mostly purchased as a unit or assembled by the plant manufacturer.

Q4: What size iron ore can the iron ore processing plant handle?

A4: The size of the iron ore material that can be processed is usually between 2.5 and 0.9 inches. This means that the final product size will range between 0.078 mm and 0.5 mm.