All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(8492 products available)

The oil level sensor can be categorized into two, which are traditional and non-contact types. Each kind has its advantages and disadvantages and can be used in different industrial situations.

This kind operates by using floats that move with the oil level. They are very reliable for large containers. They use a simple design but are very practical for many oil storage areas and tanks.

These sensors are put at the bottom of tanks and measure pressure changes based on the oil level. The pressure increases when the level rises, and it decreases when the level drops. Larger containers do well with these transducers, as they offer an accurate reading over large spaces.

These work by sending sound waves from the top of a tank to measure the oil level. They don't touch the oil, so they're ideal for dangerous or harsh liquids. However, they work best in calm and still tanks, as any movement can affect the reading. It is important to note that ultrasonic sensors are manufactured using plastic or stainless steel, whereas other types are usually made of cheap materials like metal and alloys.

These detect oil levels by measuring changes in capacitance. They accurately read levels and are good in extreme temperatures. But they are sensitive to the tank material and the oil type, so calibration may be needed. These sensors use stainless steel and other alloys as their manufacturing materials.

These sensors identify oil levels using light. They work well for small tanks and precise control but are not suitable for large or thickly industrialized tanks. However, these sensors are very reliable and provide accurate readings constantly without fail.

Industrial oil level sensors play a crucial role in monitoring oil levels across various industries. These sensors help manage resources effectively and ensure machines work as they should in these settings.

In manufacturing, machines need oil to run smoothly. Sensors monitor oil levels, so operators know when to add more. Keeping the right level prevents damage and keeps machines working their best. With constant oil monitoring, manufacturing equipment runs smoothly with fewer breakdowns.

Automobiles need sensors to monitor oil levels in both engines and other fluids. These devices alert drivers when levels are low, giving them time to refuel before running out. Sensors also help find leaks by detecting drops in oil levels.

Aerospace relies on sensors to monitor oils used in aircraft systems and engines. These sensors even work at high and low pressure and temperature in space and on flights. They help keep aircraft operating safely and efficiently during complicated trips.

Backup generators use sensors to track oil levels and ensure they can provide power when needed. This is crucial during outages or in emergencies when reliable power is a must. Sensors give early warnings to refill oil so the generator won't run dry. This ensures it works without missing a beat when needed the most.

Ships rely on sensors to check fuel oil and lubricating oil levels. These devices work in difficult ocean conditions and help prevent oil shortages on long journeys. They also monitor tank levels to prevent overfilling and spilling oil into the water, harming the environment.

In oil and gas extraction, level sensors track the amount of oil in storage tanks and pipelines. They help workers know when tanks are full or need to be emptied, preventing dangerous overflows. Sensors also measure oil levels deep underground, guiding companies on where to drill for more deposits. This keeps production running smoothly and safely.

The operating specifics and characteristics of the industrial oil level sensor are elaborated below.

These sensors give precise oil readings, so machines have the right amount of oil all the time. Keeping levels accurate boosts efficiency and stops costly errors. Their precision makes work faster and cuts down on waste and downtime.

Oil levels stay current with these sensors, providing immediate data for quick decisions. This live reading helps industries respond fast and avoid problems. With up-to-the-minute info, they can adjust levels before any issues occur.

The industrial oil gauge is made for tough places and handles extreme heat, cold, and pressure. They also resist harsh chemicals to stay strong no matter the conditions. Their rugged design ensures long-term use through any challenges.

The sensors need very little fixing, allowing workers to focus on more important tasks. They perform reliably without constant care. This low maintenance saves time and helps industries run smoothly without frequent checks.

Oil use is cut down because the sensors keep machines properly lubricated. This reduces energy waste and helps the environment. Lower usage means smaller utility bills and a reduced impact on the planet.

The following steps summarize how to install the oil level gauge appropriately.

The following steps explain how to use the oil level sensor accurately.

The following things should be done regularly to maintain the industrial oil level sensor.

It is important to keep quality and safety in mind when choosing an industrial oil level sensor because the task is risky.

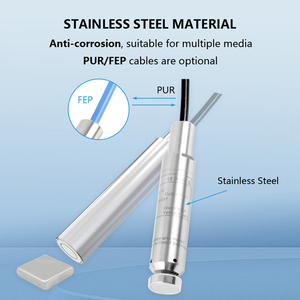

Good sensors are made of strong things like stainless steel or special plastic that don't get damaged inside by heat or pressure. These materials stop the sensor from breaking down and help it last a long time. Sensors with low-quality materials often fail, causing damage and danger.

Many sensors have seals keeping out dust and water, which could stop it from working well. Choosing a sensor with these good seals ensures nothing messes with its readings. Without a proper seal, dirt and liquid could get in, leading to wrong results and sensor failure.

Look for sensors that have industrial safety ratings and certificates. These certified sensors meet certain quality and safety rules for industry use. Pick a sensor with these certifications to be sure it follows important safety standards.

It is important that oil levels are constantly checked through industrial means. A water level gauge can monitor these levels, and when they are unsafe, it gives warnings so workers can fix the problems. It stops disasters by making people aware of any dangers in advance.

Putting the sensor in the right spot lets it work as intended. Following its installation steps makes sure it stays safe and gives good readings. Installing it improperly may lead to wrong results and make the sensor fail at its job.

The sensor's guide should be looked at for safe use and care instructions. Following these rules keeps the device safe and working well. Sensors may break or become unsafe to use if the manual is not followed.

A1: The size of this sensor depends on the size of the tank in which it is used. A small sensor will be ineffective for a big industrial tank, and conversely, a big sensor will be unsuitable for a small tank. Therefore, an oil depth sensor should be proportionate to the size of the tank.

A2: The sensor should be replaced when there are signs of wear and tear, such as some of its internal components getting damaged, some corrosion, or bad readings. Other reasons to change the sensor are when it gets clogged up with dirt and industrial wastes it cannot clean by itself and when there is an advancement in technology and better sensors are manufactured.

A3: Yes, it is very important. It increases the life of the machine by ensuring that there is always enough oil for lubrication and for doing its other tasks. Oil level moderation also boosts productivity, decreases waste, keeps the environment ideal for working, and helps in planning and management.

A4: Pressure transducers are known to be one of the most accurate sensors because they measure the pressure exerted by the oil column. This provides a precise measurement of the oil level. Other methods of measurements like floats or capacitive methods are somehow precise, but pressure transducer gives data in real time, which is accurate for monitoring constantly changing levels.

A5: Most industrial oil sensors use electricity as their power source. However, some of them are constructed to be operated without electricity, so they can operate by simply using the pressure of the oil as a source of power.