All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(170983 products available)

Steel beams come in several types. The following is a rundown.

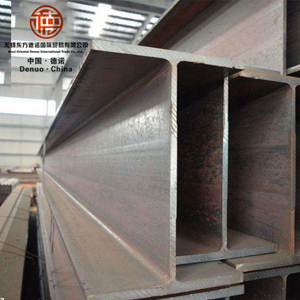

I beams

I beams are prevalent due to their structural strength and rigidity. In this case, they have a cross-sectional shape resembling the letter “I.” They are manufactured using pricey steel, which allows them to distribute weight efficiently. Often, these steel structural beams are used in construction, bridges, and other load-bearing structures.

IH or hybrid I beams

Hybrid I beams are a modification of the standard I beam. Due to this, they offer improved performance in specific applications. To clarify, they incorporate flanges of varying heights or thicknesses. While some are designed to withstand torsional stresses, others maintain bending capacity. Frequently, these steel i beams find application in specialized construction projects where unique load-bearing requirements exist.

C channel beams

C-channel beams are also known as crescent beams or S beams. These beams are essential in offering versatility in construction. Similar to I beams, they have a cross-section that resembles the letter C. They are commonly used in framing, brackets, and supports. In these applications, lesser load-bearing capacity is required. These steel beams, therefore, provide flexibility and lighter weight. Because of this, they adapt to varied engineering requirements.

L beams

L or angle beams are designed with an L-shaped cross-section. Often, they are useful in reinforcing structures. Commonly, these steel support beams provide added support for corners and edges. Therefore, this makes them ideal for use in both construction and machinery.

T beams

T beams have a cross-section that looks like the letter T. They are commonly used in constructing floors and ceilings. Often, these beams are manufactured from reinforced concrete. The concrete used here is very heavy, thereby providing a strong, durable, and lightweight material. Additionally, T beams are vindicated for their efficient use in spanning large distances.

Rectangular and square beams

Rectangular and square beams are known for their equal load-bearing capacity in multiple directions. This quality comes in handy when used in constructions that require lateral stability. Commonly, these beams are favored in modern buildings. Here, aesthetic considerations are just as important as structural integrity.

Steel beams have many features. Here’s a look at them:

Strength and durability

Commonly, steel beams are well celebrated for their remarkable strength and longevity. To elucidate, steel is an alloy with immense tensile strength. Therefore, this enables steel beams to support heavy loads without warping or cracking. Often, their durability makes them suitable for use in construction projects. Particularly, these projects have to withstand the test of time and adverse weather conditions.

Lightweight construction

Steel beams are lightweight when compared to other materials like concrete. This reduces the overall weight of a structure. Further, their lighter weight makes them easier to handle during installation. It also requires less manpower and lighter machinery. Sometimes, this is what results in lower construction costs.

Versatility and Application

Steel beams are available in varied sizes and shapes. Due to this, they come with immense versatility. More importantly, they make them applicable in diverse construction projects. Usually, they are applied in residential buildings, commercial structures, bridges, and industrial facilities. Furthermore, they serve as fundamental components in supporting roofs, floors, and load-bearing walls. This makes steel beams indispensable in creating structural frameworks.

Corrosion resistance

Steel beams are often treated with protective coatings such as galvanization or anti-corrosive paint. Conventionally, these treatments offer them exceptional resistance to rust and corrosion. In addition, this is particularly vital in environments that are exposed to moisture or extreme temperatures. Such conditions typically lead to corrosion. Moreover, this long-lasting protection ensures that steel beams maintain their structural integrity over decades.

Eco-friendly

Steel beams are manufactured from recycled materials. Hence, this makes them an eco-friendly option. Furthermore, steel itself is highly recyclable. This contributes to sustainability in construction practices. Also, the longevity and reusability of steel beams minimize the consumption of resources. Therefore, they make a positive impact on the environment.

There are a myriad of uses for steel beams. They include:

Structural Support

Steel beams are ideal for providing structural support in buildings, bridges, and other constructions. After all, they are designed to bear heavy loads and distribute weight throughout a structure. Therefore, this ensures stability and prevents collapse. Also, their high strength-to-weight ratio allows for long spans without the need for intermediate supports. This creates open spaces in architectural designs.

Used in frame constructions

Often, steel beams are integral components of frame constructions. These frames offer the necessary rigidity and flexibility to withstand dynamic forces like wind and earthquakes. Regularly, these beams are used in combination with other materials. For instance, concrete and wood integrate into composite structures that have enhanced load-bearing capacities.

Application in ceilings and flooring

Steel beams support floors and ceilings by carrying the weight of these elements and any furnishings or occupants. Therefore, this makes them essential in multi-story buildings. Here, they help in transferring loads to the foundation. Frequently, steel beams function as pivotal components in creating false ceilings. In such cases, they allow for the installation of additional architectural features while maintaining structural integrity.

Industrial applications

Steel beams have countless uses in industrial settings. Specifically, they support machinery, equipment, and piping systems in factories and warehouses. Also, due to their strength and versatility, they are used in the construction of large-scale facilities. These include manufacturing plants, where heavy loads must be supported constantly.

Bridge Construction

Steel beams are a staple choice in bridge construction. This is due to their ability to span long distances while sustaining immense loads. Additionally, steel's flexibility enables it to absorb shocks, making bridges safer in transit operations. This includes carrying vehicles, pedestrians, and trains.

Overhead gantry cranes

Steel i beams play an important role in making overhead gantry cranes. These cranes lift and move heavy objects in manufacturing plants, shipyards, and construction sites. Commonly, the beams form the horizontal rails. This allows the crane to travel and support the loads being lifted. Also, because of their strength and precision fabrication, steel beams enable these cranes to operate smoothly and safely across various industrial environments.

To choose steel beams for sale, buyers should consider the following factors:

Steel beam types

Steel beams come in diverse types. For instance, there are i beams, h beams, t beams, and l beams. Each of these types has a unique application. For instance, i beams are often used in construction because of their strength and load capacity. They are also symmetric. On the other hand, h beams are wider. They offer better stability and are used in heavy construction. The l beams, on the other hand, are suited for structural support at right angles. They, both of these types, have unique buyers should understand the beam type they need based on the construction requirements at hand.

Weight and size

This is directly proportional to the structure's height and width. Therefore, buyers should get beams in various standard dimensions. The thickness and width are supposed to vary to cater to specific structural requirements. More importantly, considering the weight of these beams is essential. The reason is they can affect the ease of handling during installation. Also, heavier beams may necessitate more powerful lifting gear and equipment.

Steel beam load capacity

Before settling for certain steel beams, buyers should ensure they can handle the required load capacity. These include both the dead and live loads. They should also consider the span lengths because they affect deflection. So, steel beams with high load capacity have minimal deflection.

Corrosion resistance

Buyers should get beams with added corrosion resistance. Ideally, beams labeled as weathering steel are used for outdoor projects. Such beams develop a protective layer over time. In some instances, buyers may settle for galvanized or coated beams. These are coated with different zinc varieties to protect them from even harsher environmental conditions.

Beam cost and quality

To make a reasonable choice, one has to factor in both price and the quality of the chosen steel beams. In this case, the quality of steel used will affect the strength and durability of the beams, thus affecting the structure's safety. The common cause of price variations is the grade of steel. Generally, higher grades offer better performance. Buyers can also consider buying beams in bulk. They can negotiate for a discount.

Usually, the amount of load i steel supports depends on beam size, material, and design. Typically, longer beams deflect more under the same load. Also, wider and thicker beams have higher bending moments. Therefore, the actual load a steel beam can handle is typically calculated using engineering formulas that consider these factors. Additionally, local building codes offer guidelines on acceptable load limits.

Usually, the difference between IPE and IPN steel lies in their flange width and usage. For instance, IPE beams have narrow flanges. This makes them ideal for situations where depth reduction is needed. On the other hand, IPN beams have wider flanges. This makes them suitable for applications requiring greater load-bearing capacity since they are heavy-weight beams. Although both are European-standard profiles, their distinct structural advantages cater to different engineering needs.

Often, steel beams are prone to corrosion, especially if exposed to moisture, chemicals, or salty environments. Nevertheless, some steel beam varieties have been treated to offer them resistance against corrosion. The most common treatment methods include galvanization, corrosion-resistant coatings, and environmental control. Regular maintenance of the beams also aids in preventing long-term corrosion effects.

Yes. When exposed to extreme heat, steel beams expand. Usually, the higher the temperature, the greater the expansion rate. Nonetheless, this expansion is typically restrained within the structural framework. In such cases, it can lead to internal stress. Often, if these stresses surpass the steel's yield strength, deformation occurs. That’s why in cases where fire is anticipated, expansion joints are included to accommodate the thermal expansion of steel beams.

To sum up, buyers should settle for steel beams that meet the structural requirements of the intended project. They should consider the preferred beam type, the load it will carry, its size and weight, and whether it is corrosion-resistant. Moreover, they should buy the beams from trusted suppliers on Alibaba.com. They can also opt for stainless steel beams for sale for an eco-friendly option.