All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(431 products available)

A hydraulic flange spreader kit is a comprehensive set of tools designed for efficient flange separation in industrial applications. The spreaders utilize hydraulic force to generate precise, controlled expansion, making them ideal for tackling stubborn or heavily bolted flanges.

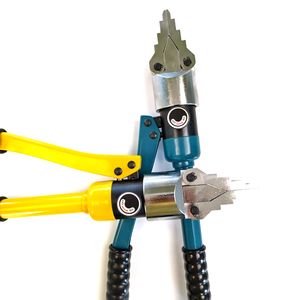

Standard hydraulic flange spreaders are widely used for basic flange separation tasks in many industrial applications. These compact tools use hydraulic pressure to create a controlled gap between flanges, making it easier to remove or replace components. Their straightforward operation and effectiveness make them suitable for routine tasks.

These hydraulic flange spreaders are particularly designed to handle the increased demand of larger projects. Offered in various sizes, these spreaders employ powerful hydraulic systems to deliver high torque and spread flanges over greater distances. Usually constructed from durable materials such as high-strength steel or aluminum alloy, these spreaders are meant to withstand rigorous operations.

These kits feature a hydraulic pump, which offers the user high control over the spreading process. This combination ensures that the hydraulic force is evenly distributed, minimizing the risk of flange damage during separation. These user-friendly kits improve operational efficiency by reducing the time needed for separation tasks.

The strength of a hydraulic flange spreader is one of the most important specifications. The hydraulic flange spreader's load-bearing capacity is determined by its maximum strength, measured in tons. Larger or heavily bolted flanges needed in industry would require hydraulic spreaders with higher load capacity.

The hydraulic spreader's output is another important specification. The pressure ratio refers to how much pressure the pump can generate compared to the input. A higher ratio means more powerful spreading, which is useful for tough flange separation jobs. The bore size of the cylinder determines the spread's width, while the stroke length indicates how far the spreader can extend. Smaller spreaders with shorter strokes work well for tight spaces, while larger, longer ones are necessary for big jobs.

Materials used determine how a hydraulic flange spreader functions. Hydraulic flange spreaders often use steel alloys. These materials provide tensile strength and hardness for long-lasting performance. The hydraulic pump often contains lightweight aluminum to decrease worker fatigue without sacrificing oomph.

In any business, maintenance is very crucial, and here are some ways to guarantee the longevity of hydraulic flange spreaders:

The hydraulic system of a flange spreader can be categorized as a single-acting system. In the single-acting system, hydraulic fluid moves to extend the tool, and the spring returns it. The tool spruce costs less, but it takes longer to spread a flange. The double-acting hydraulic system is more efficient as fluid powers the tool in both directions, extending and retracting. Double-acting spreaders spread flanges faster and more precisely but are about 30% more expensive than single-acting ones, making them ideal for heavy workloads.

The load-spreading capacity of the hydraulic flange spreader is crucial. Bigger, high-capacity spreaders are needed to handle large flanges in industry. Only a small spreader system suffices for maintenance tasks on modest flanges. The bore size of the cylinder affects the efficiency and the smoothness of the hydraulic fluid's flow. Larger bore sizes enhance fluid movement, increasing flange spreaders' load capacity and speed. Monthly cleaning of bore size cylinders is mandatory to remove debris that hinders the effective hydraulic fluid movement. Also, consider the stroke length. Shorter strokes work well for small tasks, while longer are suitable for big jobs requiring greater separation.

This is the time it takes the hydraulic flange spreader to finish its task. Single-acting spreaders are slower, taking several minutes to complete, although it depends on the flange size and the force needed to spread it. Double-acting spreaders are faster, usually under a minute, especially when dealing with smaller flanges. Maintenance tasks that require less spreading tend to use single-acting spreaders. However, quick, high-volume spreading requires double-acting flange spreaders, particularly in large industrial setups.

Hydraulic flange spreaders are crucial tools in petrochemical processing. They facilitate maintenance by allowing the safe separation of flanges from pipelines, reactors, and vessels without damaging the equipment. Their ability to handle large, tightly bolted flanges makes them essential for routine maintenance and emergency repairs.

Flange spreaders are used to maintain and repair pressure vessels and reactors in vessel maintenance. They enable safe and efficient removal and installation of manways, nozzles, and other heavy components. This reduces labor-intensive bolting and speeds up critical maintenance procedures, enhancing uptime in facilities.

In oil and gas extraction, hydraulic flange spreaders aid pipeline installation and disassembly. They handle the enormous forces involved in bolting flanges, permitting the safe and efficient construction or maintenance of pipelines. Their portability also enables usage in remote locations, critical for field operations.

Hydraulic flange spreaders are extensively used in manufacturing to maintain large machinery and equipment. They are employed to disassemble components for replacement or repairs in facilities with large pressure vessels, heat exchangers, and other heavy equipment. They streamline maintenance procedures, reducing downtime and labor costs.

In marine industries, hydraulic flange spreaders aid ship and offshore platform maintenance. They permit the easy separation of flanges on large marine structures, essential for repairs and upgrades. Their capacity to work in challenging marine environments makes them indispensable for maintaining the fleet's safety and reliability.

In power generation plants, hydraulic flange spreaders maintain turbines, boilers, and heat exchangers. They safely and efficiently disassemble flanged connections, essential for major maintenance projects.

A1: Hydraulic flange spreaders are used to safely and efficiently separate welded flanges in high-pressure systems using controlled hydraulic force.

A2: These spreaders are commonly used in industries like petrochemicals, oil and gas, power generation, marine, and heavy manufacturing, where maintaining large equipment is necessary.

A3: By applying even, controlled pressure, spreaders reduce the time and labor required to dismantle flanged connections and minimize the risk of damage to surrounding components.

A4: Single-acting spreaders are cheaper but slower, while double-acting spreaders are more efficient and faster. Double-acting spreaders are ideal for heavy workloads because they provide more precise control by using hydraulic fluid to extend and retract the spreader jaws.

A5: Regularly inspecting for damage, cleaning after use, lubricating moving parts, storing in a protective environment, and checking hydraulic fluid levels can maximize the lifespan.