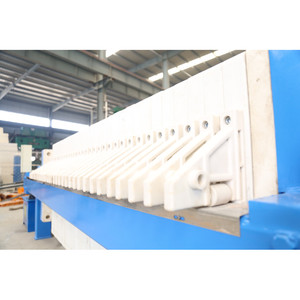

Introduction to Hydraulic Filter Media Pleating Machine

The hydraulic filter media pleating machine is an essential piece of equipment in the manufacturing of filtration products. Designed to deliver precision and efficiency, this machine specializes in the pleating of various filter media to enhance filtration capabilities and optimize performance. In an era where quality and reliability in filtration systems are paramount, the hydraulic filter media pleating machine stands out as a vital contributor to producing high-quality filters that meet diverse industrial needs.

Types of Hydraulic Filter Media Pleating Machines

The market offers several types of hydraulic filter media pleating machines, each addressing specific manufacturing requirements. Understanding these types can help businesses choose the most appropriate option for their production needs.

- Manual Pleating Machines: These machines are ideal for small-scale operations or businesses just starting in the filter manufacturing sector. They provide cost-effectiveness and flexibility, making them easier to operate without significant technical knowledge.

- Semi-Automatic Pleating Machines: Bridging manual and fully automatic machines, semi-automatic models require some human intervention but significantly reduce labor intensity. They are suitable for medium-scale production.

- Fully Automatic Pleating Machines: These high-capacity machines allow for continuous operation and minimal manual oversight, perfect for large-scale manufacturers looking to maximize efficiency and output.

- Customizable Pleating Solutions: Many manufacturers offer customized machines tailored to specific filter media requirements, ensuring that businesses can produce unique pleated designs with precision.

Function and Features of Hydraulic Filter Media Pleating Machines

The functionality and features of hydraulic filter media pleating machines are critical for ensuring optimal performance and reliability. Key features include:

- Hydraulic Pressure System: Provides consistent pressure during the pleating process, ensuring uniform pleat height and spacing, which is essential for effective filtration performance.

- Adjustable Pleating Depth: Operators can easily modify the pleating depth, allowing for versatility in producing filter media for various applications.

- Speed Control: Advanced speed controls enable operators to adjust production speeds based on material types or production volume requirements.

- Easy Interfacing: Modern machines come equipped with user-friendly interfaces, allowing for intuitive operation and quick setup changes without extensive training.

- Durable Construction: Made with high-quality materials, these machines are built to withstand rigorous production environments, ensuring longevity and minimal maintenance.

Applications of Hydraulic Filter Media Pleating Machines

The versatility of the hydraulic filter media pleating machine makes it suitable for a wide range of applications across various industries:

- Automotive Industry: Used for producing oil, air, and fuel filters that meet rigorous standards for performance and durability.

- Industrial Filtration: Essential for creating filters used in factories, ensuring clean air and fluid systems in manufacturing processes.

- HVAC Systems: Produces high-efficiency particulate air (HEPA) filters that help maintain air quality in commercial and residential buildings.

- Water Treatment Plants: Vital in the manufacture of filters used for purifying drinking water and treating wastewater, ensuring compliance with health regulations.

- Pharmaceutical Sector: Critical in the production of filtration products designed for sterile environments, where contaminant control is crucial.

In conclusion, the hydraulic filter media pleating machine not only enhances production efficiency but also significantly contributes to the quality and effectiveness of filtration systems. Its various types, functions, and applications make it a key asset in any filtration manufacturing operation, ensuring that businesses can meet the increasing demands of diverse industries.