(40 products available)

The HS code forming machine, also known as the Harmonized System code forming machine, is a device that employs a series of processes to shape metal or other materials into precise configurations. The creation of the HS code forming machine was a significant step in the manufacturing industry, introducing automation and precision into the forming processes. The harmonized system codes are essential for international trade, ensuring a standardized method for classifying goods. An HS code forming machine is designed to streamline the production of formed materials while adhering to the specifications outlined by the harmonized system codes. The extensive use of these machines has revolutionized various industries, including automotive, construction, and aerospace, by offering efficient and accurate forming solutions. Browse through the vast collection at Alibaba.com.

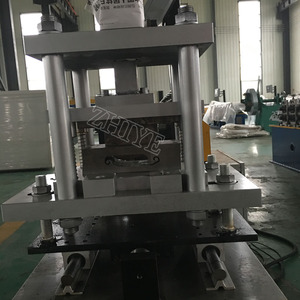

A press brake is a type of the HS code forming machine that uses a hydraulic or mechanical mechanism to bend the material along a predetermined axis. These machines are commonly used to create V-shaped, U-shaped, or custom bends in sheet metal or plates. Meanwhile, a roll forming machine, featuring a series of rollers, gradually shapes the material as it passes through the machine. This type of the HS code roll forming machine is utilized in producing continuous profiles, such as those found in roofing, siding, and steel framing systems. In contrast, a stamping press applies force to blank sheets or coils of material, creating complex shapes through a combination of cutting, bending, and forming operations. These machines are ideal for high-volume production of intricate components, making them common in the automotive and appliance industries. A tube bending machine is specialized in bending tubes and pipes to precise angles and radii, essential in industries like construction, furniture, and automotive for creating structures, frames, and exhaust systems. Lastly, a press machine applies pressure to a material to form it into a desired shape. These machines can be used for various forming processes, such as blanking, embossing, and deep drawing.

Some of the materials commonly employed in the construction of the HS Code forming machine include structural steel, known for its strength and durability, making it suitable for the robust frames and components of these machines. Additionally, cast iron is used in certain machine components for its wear resistance and dampening properties. High-strength alloys are utilized in the manufacturing of critical components, ensuring the machine can withstand the forces involved in the forming processes. Aluminum is incorporated in components where lightweight construction is essential. Moreover, composite materials are increasingly used in modern machine design to achieve a balance of strength, weight, and corrosion resistance. On the contrary, a hydraulic system in the HS Code Forming Machine operates through the use of fluid pressure to generate force. Hydraulic systems are widely used in forming machines due to their ability to provide high forces, precise control, and adaptability to various applications. Browse the extensive collection of forming machine HSN code at Alibaba.com.

The applications of the HS code forming machine are diverse. In the automotive industry, these machines are used to form body panels, frame components, and exhaust systems. The construction sector employs forming machines to create structural elements, roofing materials, and facade components. Aerospace manufacturers utilize these machines to shape intricate components for aircraft and spacecraft. In the furniture industry, forming machines are used to craft metal or wooden elements for chairs, tables, and cabinets. Additionally, the appliance sector relies on forming machines to create components for refrigerators, ovens, and washing machines. The energy industry uses these machines to fabricate parts for renewable energy systems and conventional power plants. Furthermore, the electronic sector employs them to manufacture casings, frames, and heat sinks for electronic devices. The medical field uses forming machines to shape components for medical devices, equipment, and implants. Browse through the vast collection of forming machine HS code at Alibaba.com.

The primary advantage of the HS code forming machine is its ability to create complex shapes with high precision. This precision is vital in industries where accurate dimensions are crucial for the performance and safety of the final products. Moreover, forming machines offer high efficiency and productivity by automating repetitive forming processes. This automation not only increases output but also enhances consistency in the produced parts. The flexibility of these machines allows for quick tooling changes, making them adaptable to diverse manufacturing needs. Additionally, the use of forming machines reduces material waste, as the processes are optimized to utilize raw materials efficiently. The enhancing safety features in modern forming machines prioritize operator well-being. The advancements in control systems and automation technology contribute to the ease of operation and monitoring, further enhancing workplace safety. Lastly, the environmental benefits of these machines include reduced energy consumption through efficient processes and the ability to recycle scrap material. Find a wide range of the roll forming machine HS code at Alibaba.com.