All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2605 products available)

Industrial sight glass manufacturers create these products in various types. Some of the most popular ones are listed here.

High-temperature sight glasses are often found in pressure vessels and reactors. They allow the safe and effective monitoring of substances at extreme temperatures. Experts create these glasses using durable materials. Examples are heat-resistant glasses. The glasses maintain clarity and structural integrity in very hot environments.

Reflex sight windows feature a channel or groove along one side. It helps to observe liquids in pipes. The channel diffracts light. This creates a contrast between the glass and the liquid. It makes it easier to see liquid levels or flows. People use reflex sight glasses in many applications. Some are in water treatment and chemical processing.

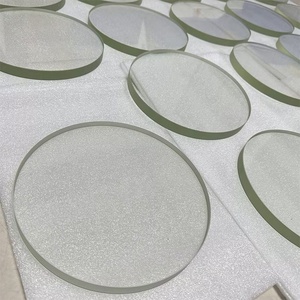

These sight glasses offer a clear view of the contents within a container or pipeline. They do not provide optical properties like the previous classes. Transparent sight glasses are suitable for low-pressure applications. They handle moderate temperatures. These are commonly used in food processing, pharmaceuticals, and HVAC systems.

People use these sight glasses for level and flow indication. They offer a visual representation of liquid levels in tanks and vessels. These glasses can incorporate materials to withstand high pressures and temperatures. Some include temperature-resistant glasses. This makes them ideal for extreme environments. Industries commonly use them in oil and gas, power generation, and metal refining.

Industrial sight glass suppliers outfit their products with different features. The ones below are the most visible ones.

The most prominent feature of high-temperature sight windows is resistance to heat. Experts test them to ensure they remain structurally sound above 300 degrees Celsius. This property ensures they function effectively in situations that require extreme temperatures.

Manufacturers also ensure the glasses can maintain clarity even after long exposure to heat. Optical clarity is critical in many industries like power generation. That is why they check for distortion or opacity after prolonged heating. Users need an unclouded view of interior processes for optimal monitoring and control.

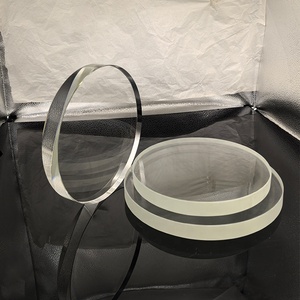

High-temperature sight glasses also have impressive pressure numbers. They can withstand pressures reaching up to 50 bar or more. This feature makes it possible to use them in applications involving high-pressure steam or gas. Such situations are usually encountered in chemical reactors and boilers.

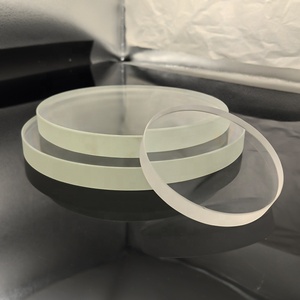

Manufacturers make these glasses from materials such as quartz glass, borosilicate glass, and ceramic. These metals can handle hefty thermal stress without breaking down. People prefer sight glasses made of these materials due to their excellent mechanical and thermal resistance properties.

High-temperature sight glasses have many commercial uses. They wholly fit the needs of different industry verticals due to their unique features and durability.

The petrochemical processing industry uses high-temperature sight glasses in oil refineries. They build reactors and distillation columns to monitor the internal processes safely. Also, the glasses allow operators to check the status of materials without opening containers. This capability improves efficiency and safety. It also provides a non-intrusive way to visualize the chemical separations taking place within.

These high-temperature glasses also have a prominent application in the metallurgy industry. People use them to witness molten metals in furnaces and ladles. Manufacturers make the glasses with materials that withstand thermal shock. This property ensures longevity in environments above 1,000°C. They help metal processors monitor metal quality and flow without disrupting operations.

High-temperature sight glasses have placement in glass manufacturing furnaces. They allow operators to monitor glass melts. People use them to check raw materials without opening furnaces. This capability leads to better quality control. In addition, the glasses help technicians ensure the melting process is uniform and up to standard without sacrificing energy efficiency or safety.

Factories use high-temperature sight glasses in industrial ovens for metal annealing and drying. It helps to monitor products such as ceramics and composites as they cure. The glasses allow users to ensure that temperature profiles remain consistent during critical processes. This observation leads to improved product quality and reduced defects in finished goods.

Choosing the best sight glass for an industry requires considering many factors. They will be explored further down this article.

Considerations in this stage require understanding the operating environment. One must ask how to and what the sight glass will be exposed to. One must think of the pressures, temperatures, and chemical interactions involved. All these factors go a long way in determining suitability. They will help decide which materials and designs will best serve the purpose.

High-temperature sight glasses should have good optical clarity. This property ensures users can effectively monitor the internal processes of their containers. So, conducting tests to guarantee minimal distortion or opacity is necessary. Opacity will compromise the visual quality of the materials. People will also need an unclouded view to make critical operational decisions.

High-temperature sight glasses use various materials. Each is compatible with multiple industries. For instance, borosilicate glasses have impressive thermal shock resistance. This ability makes them ideal for chemical plants and laboratories. On the other hand, quartz glasses stand up to extreme heat in metal refineries. Knowing which material suits an operating environment will help one get the best option.

If customers operate in industries with strict safety regulations, the supplier will need to provide customizations. They could be sight glass holders or gaskets made to match existing equipment. Also, certifications like ASME or API compliance are essential. They will ensure the equipment meets the required safety and performance standards.

A. The primary purpose of these glasses is to enable the safe monitoring of substances. This feature makes them vital components in many industrial processes. People favor them for their durability and key role in maintaining operational efficiency.

A. These sight glasses have applications in various industries like petrochemicals, metallurgy, power generation, and glass manufacturing. They are suitable for monitoring internal processes under extreme operating conditions in each of these industries.

A. Most high-temperature sight glasses have impressive pressure ratings. Some even go up to 50 bar. People specifically design these glasses to endure both high pressures and extreme temperatures. This property makes them ideal for vision equipment under harsh operating conditions.

A. Manufacturers typically make high-temperature sight glasses from quartz glass, ceramic, or borosilicate glass. Quartz glass has impressive optical clarity and thermal shock resistance. Boroilicate glass also offers superb chemical resistance and clarity. Its indentation resistance comes in handy, too. Lastly, ceramic offers excellent insulation properties.

A. The maintenance requirements will depend on the specific application. Operational factors like exposure to chemicals or particulate matter will determine the maintenance required. Regular cleaning to prevent residue build-up usually suffices.