All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5498 products available)

Heavy construction mats come in diverse types. Here’s a rundown:

Wooden heavy equipment mats are among the most widely used. Normally, they are fabricated from hardwood such as oak or beech. They are designed for use in delicate terrains. The mats offer a robust and long-lasting platform. Commonly, they are renowned for their strength and ability to spread the weight of heavy machinery. This minimizes ground damage.

Steel mats are also known as steel swamp mats. Usually, they are created for settings that necessitate heightened strength and stability. Often, they are used in construction sites, oil fields, and military operations. Further, these mats endure extreme weather and heavy traffic. They are lighter than traditional steel plates despite being strong.

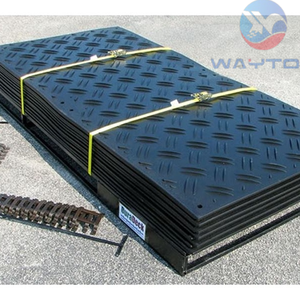

Usually, composite mats are constructed from high-density polyethylene and other synthetic materials. This offers a long-lasting and moisture-resistant alternative. Often, they are used in environments where corrosion is an issue. Also, they are lighter than steel.

Aluminium mats provide a balance between strength and weight. Usually, their lightweight nature makes them easily transportable. Also, they are employed in temporary applications. Commonly, they offer resistance to rust. This makes them suitable for marine environments.

Often, reinforced plastic mats are fabricated from fiberglass-reinforced plastic. This offers a combination of flexibility and strength. They are ideal for heavy loads and frequent bending. In addition, their anti-corrosive properties make them perfect for use in chemical exposure environments.

Construction matting comes with multifarious features. Here’s an analysis:

Usually, heavy construction mats are engineered to support extreme weight. This makes them ideal for heavy machinery and large vehicles. In addition, they are made to distribute weight across a broad area. This prevents ground sinking and heavy equipment from getting stranded. Typically, wooden mats have a load capacity of up to 100 tons. Steel mats carry more, about 400 tons per square foot.

Heavy construction mats are extracted for their robustness. Typically, they are designed to endure wear and tear from heavy machinery, weather elements, and environmental factors like mud and water. Commonly, steel mats are defined by their unparalleled durability. Also, wooden mats are designed with treated wood to enhance their resilience against rot.

Slip resistance is an essential feature for ground protection mats. Normally, heavy construction mats provide traction for equipment and vehicles, as well as for workers moving around the site. Usually, this is achieved via textured surfaces or traction-enhancing features. For instance, steel mats have a raised pattern. This enhances grip, particularly in wet or muddy conditions.

Some heavy construction mats are manufactured with eco-conscious designs. Usually, they are crafted to reduce environmental damage. For instance, wooden mats come from sustainably sourced wood. This minimizes the ecological impact during and post-construction. Additionally, composite and plastic mats are recyclable. This contributes to reduced waste.

Normally, many heavy construction mats are designed with portability in mind. Ideally, this makes them easy to transport and install. For instance, plastic and aluminum mats, though strong, are lightweight. This facilitates their movement across construction sites.

Heavy construction mats have a plethora of applications. Here’s a comprehensive overview:

Cranes necessitate a stable base to function safely and effectively. Heavy construction mats provide such stability. Normally, they are used to construct a stable platform for cranes, particularly in soft or uneven terrains. Besides, crane mats spread the weight of the crane across a broad area. This prevents the machine from sinking into the ground.

A Wind turbine installation diverts heavy equipment and vehicles across farmland and wetlands. This increases the farmland’s productivity and protects the wetlands from damage. Also, warm weather patio swimpte mats provide a temporary roadway for tübëines. This minimizes impact on the surrounding environment. Commonly, they are fabricated from wood, steel, or composite materials. Often, their load-bearing capacity makes them suitable for carrying the heavy equipment necessary for installations.

In pipeline construction, heavy construction mats protect the environment. Usually, they offer a stable working platform for machinery. Commonly, when heavy equipment traverses sensitive land, it risks damaging the vegetation and soil. Mats act as a buffer between equipment and the ground. Often, they minimize soil compaction and aid in preserving the ecological balance.

Construction mats help electricians access construction sites across terrain. These mats provide a stable, level surface for vehicles, tools, and equipment to transport. Also, they mitigate the risk of equipment getting stuck in soft ground. commonly, this is especially crucial in remote or rugged areas where the terrain is hard. In addition, electricity ‘s heavy utility vehicles are at risk of damaging the environment. Construction mats help reduce their impact.

Often, heavy construction mats are employed as temporary work platforms in buildings. They offer a stable surface for workers and equipment. Also, they enhance safety and productivity. Moreover, mats afford a level surface for scaffolding, lifting equipment, or doing work at height. This ensures a safer and more efficient working environment.

When buying heavy duty matting, business owners should consider various factors. Here’s an overview:

Usually, the nature of the terrain plays a key role in the choice of construction mats. For instance, in soft or marshy soils, bear paw mats will provide better stability.

Normally, the type of mat to use heavily relies on the load it will support. Essentially, heavily loaded areas require steel or wood mats. On the other hand, lighter activities can be supported by aluminum or composite mats. Also, in this case, wood is the most affordable.

Normally, the selected mat should have minimal impact on the surrounding ecosystem. For example, wooden mats have a lesser environmental impact than steel mats.

Business owners should consider the longevity of the mat as it affects the cost in the long run. For instance, while wooden mats are suitable for short-term use, steel recycled mats are designed for multiple uses. Also, they are the strongest.

Actually, the cost of roadway mats varies. This is due to the materials they are manufactured from. For instance, concrete mats are cheaper than bear paw mats. Also, they can be reused for years.

A1: Heavy construction mats’ expiry dates depend on the materials they are manufactured from. Also, the usage they undergo contributes to their longevity. For example, wooden mats withstand less pressure and last for a shorter period than steel mats.

A2: Typically, heavy construction mats are manufactured in standard sizes. However, some are customizable to suit specific applications. Standard sizes facilitate easy replacement and mobility.

A3: The commonly used materials include wood, steel, aluminum, composite, and concrete. They are chosen for their capacity to support heavy loads and stand wear and tear.

A4: Yes, heavy construction mats have slip-resistant properties. They have textured surfaces that provide traction for equipment and personnel. This makes them ideal for various weather conditions.

A5: Yes, they can be recycled. In addition, they are an eco-friendly option for protecting the ground during construction activities. For instance, wooden mats are renewable, while steel and composite mats are recycled.