All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1546 products available)

In any established business, understanding the types of hdpe butt fusion elbow 90 fittings is crucial for making informed decisions when purchasing items or products. These are the different types of these fittings's structural and functional characteristics.

As an elbow 90 degrees fusion hdpe fitting, a butt fusion machine is sometimes manually operated to fuse two HDPE pipes into a rigid connection; thus, creating a permanent joint that allows for a change in fluid direction. Plastic fittings are the most common due to their excellent corrosion resistance properties. Businesses in the chemical and water industries, where such products are frequently transported, therefore need these type of fittings. These lightweight, cost-effective fusion fittings are not only resistant to chemical corrosion but also to weathering and UV radiation.

Butt fusion 90 EL HDPE steel elbows are made of HDPE and carbon or stainless steel used for high-pressure applications. They provide structural strength and are used in oil and gas transportation and other high-pressure fluid systems. In construction, carbon steel fittings are valued for their superior strength, making them indispensable in heavy-duty applications.

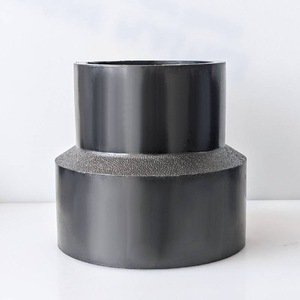

Reducing fusion 90-degree HDPE elbows are designed to connect pipes of different diameters, enabling smooth fluid passage between them with varying pipe sizes. They are necessary for complex piping systems where space is limited and different pipe sizes are needed. In HVAC systems, these fittings are frequently used to transfer air efficiently through varying duct sizes.

HDPE threaded 90-degree fusion fittings are fusion fittings on one end and threads on the other for easy connection with other threaded components. They are ideal where a permanent fusion joint is required alongside a threaded connection for easy disassembly. These fittings are common in agricultural irrigation systems where frequent component replacement is necessary.

The degree to which HDPE butt fusion el 90 fitting is fused is greatly determined by the nature of the industry and how the degree of fusion is carried out.

Water supply systems frequently use hdpe butt fusion elbow 90 fittings since they provide reliable, long-lasting connections in the HDPE piping systems required for delivering clean water. Fusion joints eliminate leaks commonly found in traditional joints, thus enhancing system efficiency and reducing maintenance costs. Also, thanks to the fittings' corrosion resistance and sturdiness, they are long-term-employed by municipal and residential water distribution systems.

Fusion 90 HDPE el long fittings and strong, leak-proof connections that are critical for operational safety in this field. These fittings are commonly used in low to medium pressure natural gas distribution lines and other fluid transportation pipelines. Their chemical resistance and durability make them suitable for transferring corrosive substances and ensuring the integrity of petroleum products' pipelines.

Irrigation systems use many HDPE butt fusion el 90 fittings because they efficiently manage water supply to crops. These fittings link piping quickly to ensure water is evenly distributed without wastage. Since HDPE is lightweight, easy to install, and resistant to most chemicals found in fertilizers and pesticides, it is ideal for use in agriculture. It helps in reducing system maintenance, thus increasing the system's overall reliability.

The mining industry uses HDPE fusion fittings in numerous applications, such as transporting water, slurry, and other chemicals. Their strength, flexibility, and resistance to chemical corrosion make them suitable for extreme conditions found in mining sites. The 90-degree elbows are particularly useful in assisting pipes to navigate rugged terrain and continue functioning, thus ensuring the continued flow of mined substances and associated liquids.

Product specifications and features are crucial when purchasing anything or any product, including the components and materials used to make HDPE butt fusion elbow 90 fittings, as well as their operational and functional attributes.

Quality and safety considerations are of prime importance when purchasing HDPE butt fusion elbow 90 fittings.The following are quality and safety considerations to look out for:

HDPE's density is relatively high, meaning its molecules have been tightly packed, resulting in a sturdy thermoplastic that can withstand adverse environmental conditions, such as chemical corrosion, UV rays, and extreme weather conditions. Only fittings manufactured from virgin-grade HDPE should be used to prevent compromising durability and fusion integrity. Recycled plastics, although cheap, contain impurities and inconsistent materials that reduce the product's mechanical strength, thus making it not suitable.

Electrofusion or butt fusion fusion fittings require heating the joining ends and fusing them to form a permanent joint. The process involves using specialized fusion machines or equipment, like butt fusion machines, which automatically control the fusion process by applying heat and pressure. Manual fusions often lead to poor joint integrity due to improper heating or misalignment. Purchasing fusion equipment from reputable manufacturers while investing in training programs for operators to help them understand the ideal fusion procedures enhances the quality of the joints.

Before putting the HDPE pipe system into service, fusion joints, including 90-degree elbow fittings, should be tested under a certain amount of pressure. It verifies that the joints are solid and leak-free. The pressure test is done by slowly filling the pipe with water or air and monitoring for any leak signs. Regular testing also ensures long-term safety; thus, the system can be proactive in identifying weaknesses before they lead to failures.

HDPE is cost-effective and durable; however, prolonged exposure to UV rays results in a breakdown of the material and the fittings, making them brittle and weak. Additives like carbon black increase the exposure time of these fusion fittings to UV rays. The black carbon not only protects the fittings but also makes them ideal for outdoor use. A 90-degree elbow fitted translucent black HDPE should suffice if the outdoor exposure duration is more than a couple of hours.

OSHA criteria for high-density polyethylene butt fusion elbow fittings are similar to those for other welding operations. Many injuries result from employees working in hot areas without proper PPE. PPE such as welding helmets, gloves, and safety glasses protects the worker's body from heating and fusion equipment and severe flashes. The working environment should be kept clean and free of obstacles that could cause workers to trip or fall. A first aid kit is also ideal for minor injuries.

A1: HDPE electrofusion 90-degree bending fittings are chemically resistant and don't rust, thus making them suitable for transporting safe drinking water. While carbon steel fittings are not directly used in drinking water transportation, they are used in underground piping systems. Other coatings, such as galvanizing or powder coating, protect them from corrosion, preventing contaminants from entering the water system.

A2: Yes, fusion fittings are made of black HDPE, which contains carbon black that acts as a UV stabilizer, making them ideal for outdoor application. However, the carbon black presence makes the fittings heat-absorbing and possibly becoming overheat if used in outdoor settings for extended periods. Despite this, they will continue exhibiting flexible and sturdy properties, which are among their key benefits.

A3: HDPE 90-degree fusion fittings are mainly used in water distribution systems due to their resistant properties in chemical corrosion, temperature, and pressure. Other areas where they are used are oil and gas lines, mining and agricultural irrigation, and geothermal systems.

A4: HDPE butt fusion fittings have a typical lifespan of 50-100 years, depending on the conditions they are exposed to during this period. Most common HDPE belt fusion fittings are used in water pipeline systems. The longevity of these fittings is due to their sturdy, corrosion-resistant, and chemical-resistant properties.

A5: Wearing specific personal protective equipment, including gloves, safety glasses, and hard hats, to protect potential injuries, adhering to OSHA standards, including avoiding confining work areas and ensuring fusion area barricades, and ensuring that the fusion area is free of flammable substances are among the measures that should be observed.