(11283 products available)

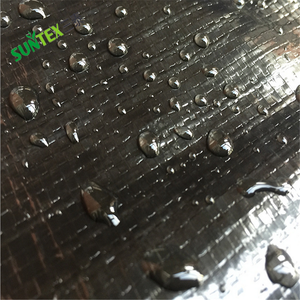

A geomembrane sheet is a thin, flexible material with impermeable characteristics. It is used in various applications, such as environmental, civil engineering, mining, and water conservancy projects. The geomembrane is made from different materials, which influence its mechanical properties, adaptability, and impermeability. Below are the types of geomembrane sheets:

High-Density Polyethylene (HDPE)

HDPE plastic sheeting geomembranes have a reputation for their durability and high chemical resistance. They are commonly used in landfills, mining, and water containment applications. They offer a cost-effective solution for projects requiring long-term containment and environmental protection. Their strength-to-weight ratio makes them suitable for various applications. They are also UV and weather-resistant, making them ideal for applications with high exposure to weather elements.

Low-Density Polyethylene (LDPE)

LDPE geomembranes are more flexible than HDPE, making them suitable for applications requiring easy handling and welding. They are commonly used in ponds, canals, and lining applications. They offer good chemical resistance and are often used in agricultural and aquaculture applications. They are lightweight and easy to install, requiring fewer tools and equipment.

Linear Low-Density Polyethylene (LLDPE)

LLDPE geomembranes combine flexibility and strength, making them suitable for applications such as landfills and reservoirs. They offer good puncture resistance and are often used in applications where the membrane may be subject to sharp objects or roots. LLDPE is popular for their ease of welding, producing strong seams during installation.

Polyvinyl Chloride (PVC)

PVC geomembranes are known for their ease of installation and welding characteristics. They are commonly used in water treatment plants, reservoirs, and swimming pools. Their lightweight nature allows for easy handling and installation. They offer good chemical resistance, particularly against acids and bases.

Ethylene Propylene Diene Monomer (EPDM)

EPDM geomembranes are rubber-based and are known for their excellent UV resistance and flexibility. They are commonly used in applications such as ponds, roofing, and landscapes. They are ideal for applications with high-temperature variations. They are also easy to install and require minimal maintenance.

Bentonite Clay

Bentonite clay geomembranes are natural and are used in applications where environmental impact is a major concern. They are commonly used in landfills and mining. They offer good self-sealing properties and are biodegradable. Environmental benefits make them suitable for projects emphasizing sustainability.

Geomembranes have different functions in construction. Their features are what make them suitable for the various functions. Below is a list of the functions and features of geomembrane sheets.

Containment

Geomembranes act as liners for reservoirs, landfills, and mining sites. They prevent water, waste, and chemicals from seeping into the soil or groundwater. The sheets create a barrier that enables hazardous waste and water to be contained safely. This is due to their low permeability.

Waterproofing

The geomembrane is used in the foundation waterproofing of buildings and structures. They prevent water from entering the foundation, which can cause structural damage. The geomembranes create a path for water to flow freely without affecting the integrity of the foundation.

Drainage

Some geomembranes, such as HDPE, have drainage functions. They are used in landfill sites and under drains. The geomembranes provide a space for water to flow and collect, thus reducing hydrostatic pressure. This protects the landfill from collapse due to water pressure.

Separation

Geotextiles separated different types of soils in construction sites. This prevents soil mixing, which can affect the integrity of the site. They prevent pipes from being damaged by rocks and other debris in the soil. The geomembranes create a layer of separation and ensure the project runs smoothly.

Support

Geomembranes are used in green roofs and other vegetation areas. They provide waterproofing and prevent plants from growing on pipelines. The geomembrane sheets offer a support layer while ensuring water does not penetrate the soil.

Gas control

Some geomembranes are used in landfills to control the movement of gases. Landfills produce methane and other gases that can be harmful to the environment. The geomembranes trap these gases and direct them to treatment facilities.

Adaptability

The geomembranes are easy to install in complex sites and terrains. They can be welded to create a large, continuous cover that protects the site from seepage and leakage. This makes them suitable for large projects like landfills and reservoirs.

Cost-effectiveness

Geomembranes are relatively inexpensive compared to other lining options. They offer a good return on investment by preventing leakage and seepage. Their durability and longevity reduce the cost of replacing the geomembranes.

Environmental Protection

Geomembranes are crucial for protecting the environment. Their ability to prevent water and soil contamination ensures ecosystems are protected. They also prevent the depletion of water sources by ensuring water is conserved and protected.

The global geomembrane market is experiencing rapid growth due to the increasing demand for geomembranes in different applications. According to a report by Fortune Business Insights, the geomembrane market will be valued at $4.09 billion by 2028, with a CAGR of 5.30% between 2021 and 2028. The demand for geomembrane in water conservation and containment, mining, and agriculture has contributed to this growth. Here are some common application scenarios of geomembrane sheets:

When selecting geomembranes for a project, it is important to consider factors to ensure the geomembranes meet the project needs. Here are some factors to consider when choosing geomembrane sheets:

Project requirements

The first thing to consider should be the project needs. Different projects have different needs, and it is important to ensure the geomembrane sheet selected meets the project needs. For example, projects that need high tensile strength and puncture resistance should go for HDPE geomembranes. At the same time, projects that need flexibility should consider using LLDPE geomembranes.

Thickness

The thickness of the geomembrane plays an important role in its durability and performance. A thicker geomembrane will be more durable and resistant to punctures or tears. However, a thicker geomembrane will be less flexible. It is important to ensure the geomembrane has the right thickness to balance flexibility and durability based on the project needs.

Permeability

Permeability refers to the ability of water to pass through the membrane. Membranes with high permeability are not ideal for containment because they allow water to pass through. On the other hand, membranes with low permeability are good for containment because they prevent water from passing through. It is important to select a membrane with low permeability for containment projects.

Climate conditions

The climate conditions of the area where the geomembrane will be used also need to be considered. Climate conditions that have high temperatures and UV radiation can damage some geomembranes, especially the PVC geomembranes. It is important to ensure the geomembrane can withstand the climate conditions of the area.

Compatibility with liquids

Some projects involve the use of liquids, and it is important to ensure the geomembrane is compatible with the liquid. Some liquids can cause the geomembrane to deteriorate or break down. As mentioned before, different geomembranes have different permeabilities.

Q1: What are the main uses of geomembrane sheets?

A1: Geomembrane sheets are primarily used for applications that require water or liquid, or even air, to be contained or controlled. This includes reservoirs, dams, and canals; landfills and waste containment; mining operations; agricultural applications; aquaculture; and artificial liners for ponds, lakes, and swimming pools.

Q2: Which is better between HDPE and LDPE?

A2: The choice between HDPE and LDPE depends on the specific application requirements. HDPE is generally preferred for projects requiring higher strength, durability, and UV resistance. In contrast, LDPE may be chosen for applications requiring flexibility and ease of welding.

Q3: How does one install a geomembrane sheet?

A3: Installing a geomembrane sheet involves preparation of the substrate, laying out the sheets, welding or sealing joints, and conducting quality control tests. It is recommended to consult the manufacturer’s guidelines or an installation expert for precise procedures.

Q4: Are geomembranes impermeable to water?

A4: Yes, geomembranes act as barriers to water and are used in applications that require water containment. However, not all geomembranes are impermeable, as some, like geosynthetic clay liners, incorporate materials that swell to form a impermeable barrier when in contact with water.

Q5: How does one maintain a geomembrane sheet?

A5: Proper maintenance involves regular inspections, cleaning, and addressing any punctures or damages. Following the manufacturer’s guidelines can ensure longevity and effectiveness of the geomembrane.