All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2442 products available)

Fuel line quick connectors serve as integral fittings meant for the swift and safe connection or disconnection of fuel lines. These connectors are not only invaluable in automotive settings but also find their application in diverse industrial and machinery-related scenarios. Below is an elaborative list categorizing the types based on their design and usage attributes.

In the automotive sector, fuel line quick connectors are the link between the fuel tank and engine, ensuring smooth fuel transfer. With the trend toward more complex fuel systems in modern cars, these connectors' pressure, temperature, and flow rate compatibility has become paramount. Their ability to enable rapid assembly in mass production without sacrificing reliability has made them essential in this field.

Fuel line quick connectors are integral in heavy machinery, connecting fuel lines under immense pressure and volume. These heavy-duty applications require connectors to withstand extreme operating conditions, such as high temperature and intense vibrations. Frequently used in excavators, bulldozers, and other heavy-duty vehicles, these connectors are built to endure demanding work environments.

In marine engineering, connectors are deployed to link fuel tanks with engines in boats and ships. These connectors typically possess corrosion resistance capabilities, commonly being stainless steel or brass to counter the marine environment detrimental influences. The reliability and safety of these connectors are pivotal in guaranteeing smooth operations in fuel delivery systems.

Quick connectors in fuel lines are employed across generators, pumps, and boilers in industrial settings. These systems necessitate connectors to handle varying fuel types, pressures, and temperatures. Quick connectors are crucial for enabling rapid maintenance and serviceability in industrial applications, where downtime can significantly affect operation efficacy.

Workers place fuel line quick connectors in construction equipment such as generators, excavators, and heavy machinery. These connectors are frequently exposed to adverse conditions, necessitating robust designs to adapt to varying fuel pressures and types. Moreover, they enable swift repairs or part replacements, minimizing process interruptions.

Fuel line quick connectors are manufactured using variegated materials, each proferring unique advantages. plastics, metals, and composites possess resilience against fuel chemicals, pressure, and temperature. connectors are crafted from premium-grade materials like reinforced nylon, who offers excellent strength, flexibility, and chemical resistance. Alternatively, the use of aluminum and brass provides enhanced durability, corrosion retardance, and heat tolerance, making them perfect for varied environmental applications.

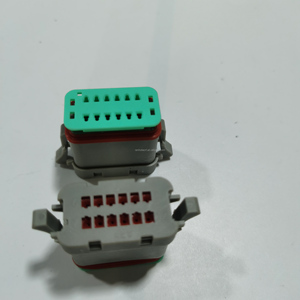

Available designs for connector types include spring-lock, push-to-connect, and clamped connectors, each catering to specific application needs. While spring-lock connectors are designed for high-pressure systems with a robust locking mechanism ensuring secure connections, push-to-connect connectors, with their simple insertion mechanism, cater to low-pressure systems requiring quick and effortless connection. Clamp-type connectors, possessing a barbed design, secure fuel lines effectively without complex locking or sealing mechanisms.

An O-ring, gaskets, or shore seals are used to enhance the quick connect fuel line, ensuring leak-proof operation. These sealing mechanisms are strategically positioned within the connector design, facilitating a tight seal between mated surfaces. O-rings are the most commonly deployed, ubiquitous in marine and automotive applications, due to their capacity to absorb more chemical strain. For extreme applications, shore seals and superior gaskets provide enhanced sealing, preventing leaks effectively.

Interchangeability standards, like SAE J2044 and ISO 17254, are delineated to offer universality among diverse connector types and manufacturers. Such standards permit the deployment of a connector from one maker onto a system featuring a connector from another, provided they meet the identical standard specification. This interchangeability eases fuel line quick connector replacement or service without system redesigning conferring flexibility and convenience in the connector selection process.

Retaining fuel line quick connector features include locking mechanisms like springs, clips, or pin-and-hole systems that secure the disconnect under operation. Spring-lock connectors incorporate a spring-loaded lock that ensures a tight and secure connection upon the release of pressure. Conversely, pin-and-hole systems simply insert a pin into a hole on the opposite side, securing the connection, typically seen in push-to-connect designs. Retention features safeguard connector disconnections and ensure reliable performance in demanding environments.

Considerations regarding fuel line quick connectors include pressure rating, fuel compatibility, connector material, sealing effectiveness, ease of installation, and system temperature variations. A proper connector should adapt to the pressure range of the corresponding fuel system to avoid connector failure. Additionally, the connector should be fuel-resistant, as the wrong material would cause degradation. Choosing connectors from reputed manufacturers ensures premium-quality materials and adherence to the industry standards. Finally, opting for a connector with an O ring or high-quality gasket will enhance fuel leak prevention. Below are the detailed specifications.

Quick connectors should be fuel-compatible, resisting degradation or failure by the constituent materials of the intended fuel. Different fuels such as gasoline, diesel, ethanol blends, and biofuels present distinct chemical properties. Thus, select a connector material specifically designed to resist the chemical nature of the fuel employed in the system to ensure long-term functionality.

Pressure ratings of fuel line quick connectors are those levels of pressure a connector can tolerate without failing. A connector that cannot handle the pressure level in the fuel system may break down or leak. Always bear in mind that the connector pressure rating should be compatible with the fuel system's pressure to preserve safety and functionality.

Temperature tolerance is a vital factor regarding the application of a quick connector for the fuel line. Extreme environmental conditions can adversely affect a connector, leading to brittleness, melting, or deformation. Therefore, select a connector possessing a temperature tolerance range that is capable of withstanding the operating environment to ensure it maintains performance and integrity.

Consider the installation ease when selecting a fuel line quick connector. Some connectors type, like push-to-connect, allow a tool-free, quick connection that is attractive for those in need of minimizing system downtime. Conversely, clamp-type connectors usually involve more complex installation processes because additional clamping is required. An easy installation reduces labor time and possible errors in connecting fuel lines.

The material composition of the fuel line quick connector defines its endurance and resistance capabilities. Commonly, these connectors are made from reinforced nylon, brass, stainless steel, or other durable alloys. Plastic connectors work well in lower-pressure systems for their flexibility and lightweight, while metal connectors ensure tolerance against high pressures, extreme temperatures, and vigorous chemical exposure. Select a durable material based on the specific application environment to ensure long-standing connector performance.

A1: Quick connectors are fuel- resistant, meaning they won't degrade or break apart due to exposure to specific fuels. These fuels include gasoline, diesel, ethanol blends, biofuels, and others. Thus, choosing a connector material that specifically resists the chemical properties of the fuel in that environment is vital.

A2: Standard interchange connectors exist, which mean a connector from one manufacturer can be used on a system employing a connector from another manufacturer. Yet, there are vehicle-specific applications. Thus, ensure the quick connector meets the manufacturer's specifications for the vehicle or machinery concerned.

A3: Several factors affect how often should a fuel line quick connector should be replaced. These factors include the operating environment, fuel type, pressure and temperature levels, and connector material. However, wear will be minimal in normal operating conditions, while extreme exposure will wear connectors more easily. For example, one may need to replace them more frequently in high-pressure, high-temperature, or corrosive environments.

A4: Yes, quick connectors for fuel lines suitable for outdoor applications are available. These connectors are usually stainless steel or brass to combat adverse outdoor conditions like moisture and temperature variations. Also, ensure the connector is rated to withstand the wind and other outdoor elements.

A5: One has to check the signs of wear or damage for the line quick connector to be replaced. These signs may include visible cracks, corrosion, looseness, or inability to secure properly. Other indications that the quick connectors have to be replaced are fuel leaks and lower system efficiency. The longer one waits, the more it compromises the safety and functionality of the fuel system.