All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2558 products available)

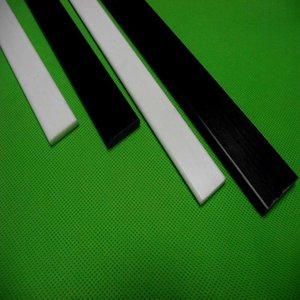

Fiberglass Reinforced Polymer strips or FRP strips are made by solidifying resin over glass fiber. Common types of strips include:

Concrete Cement Coated FRP Strips

The concrete cement-coated FRP strip type is ideal for embedding into concrete surfaces. They feature a tough cement coating that protects the fiberglass from damage while still offering a secure grip. Such characteristics make them ideal for locations where concrete is the dominant floor material, such as industrial sites or construction sites.

Clear FRP Strips

Clear fiberglass strips are famous for their transparency. This feature allows for the observation of surfaces without sacrificing strip strength. Often used in settings that require both performance and sleek appearances, like commercial swimming pools or luxurious spas, they make an ideal choice. They also have UV resistance and enhanced durability for outdoor use.

Cement Board Coated FRP Strips

Cement board FRP strips are the ideal choice for high-impact and moisture-laden environments. These strips are made tough by embedding fiberglass within cement-coated, high-density cement boards. They are very effective at withstanding water, humidity, and heavy traffic. This makes them a good choice for commercial restrooms, kitchens, or food processing facilities.

Anti-slip Coated FRP Strips

The anti-slip fiberglass trim strips are designed to improve safety by providing a slip-resistant surface. They are made for safety in wet or slippery environments, such as swimming pools, decks, and industrial sites. Some variants are outfitted with aluminum oxide or quartz anti-slip aggregates embedded in the resin. This provides a secure grip despite the danger of wetness or grease.

Anti-Corrosive Coated FRP Strips

These fiberglass strips for floors have a special coating that makes them resistant to substances that could harm them. They are made to survive harsh chemicals, humidity, and corrosive agents, such as in petrochemical plants or marine environments. They are therefore a required safety measure for any business that routinely uses vigorous substances. This also helps protect the equipment and improve safety.

High Slip Resistance

FRP strips have specially designed surfaces that greatly reduce the chance of slipping. This feature is very useful in risky locations, such as industrial plants, boats, and swimming pools. Because of their high slip resistance, accidents are less likely to happen, resulting in a safer environment for workers and visitors. The slip resistance stays strong even in wet or greasy conditions, making it functional in all situations.

Water and Moisture Resistant

FRP strips are very resistant to water and moisture. This feature makes them fit for spaces with high humidity levels or direct water exposure, such as bathrooms, pools, and outdoor walkways. Their resistance to water prevents them from becoming warped or slippery and protects the underlying structure of the flooring. This also means very little maintenance and a much longer lifespan, making them very effective in troubled areas.

Impact and Compression Resistance

FRP strips are made to withstand high-pressure and impact situations. This makes them suitable for heavy equipment areas, warehouses, or commercial activities with frequent human movement. They do not easily crack, break, or lose their shape under stress, increasing operational safety in demanding settings.

Thermal and Electrical Insulation

Favorable thermal and electrical insulating properties make FRP trim strips ideal for dangerous industrial applications. They do not conduct electricity, which lowers the risk of electrical shock and other equipment downtime. Additionally, they do not absorb heat; therefore, they do not feel hot or cold when standing on them. This feature enhances comfort while ensuring safety.

Easy Installation and Maintenance

FRP strip lights are easy to install, as they require no special tools. They can be cut to fit any space quickly and easily. Maintenance is equally simple; regular cleaning prevents dirt or grime buildup. Their durability means less frequent replacement, saving time and effort down the line.

Used in Commercial Kitchens for Flooring

The floor FRP strips are commonly used in commercial kitchens because of their anti-slip feature, which creates a safe working environment. They improve safety in critical areas such as near sinks or cooking stations, where spills cause very slippery and dangerous floors. Added durability and resistance to chemicals and moisture make them very useful for demanding kitchen environments. They also provide a low-maintenance flooring alternative because they are easy to clean and install.

Used in Decks

Due to their high slip resistance, FRP strips for decks are extensively utilized. They aid in making outdoor areas, such as pool decks and patios, safer by minimizing slip and fall incidents. Their endurance to weather elements and corrosion maintains deck aesthetics and functionality over time. Additionally, they improve aesthetics by reducing the requirement for frequent maintenance and replacement, making them a cost-effective alternative for outdoor entertainment spaces.

Used in Marine Environment

FRP trims are commonly used in marine settings because of their excellent resistance to moisture and corrosion. They provide non-slip surfaces for boats, docks, and piers, increasing safety for passengers and employees. Also, their lightweight nature does not impede the vessel's performance, while their endurance increases the vessel's lifespan. These features make FRP strips vital for keeping safety standards on marine facilities.

Used in Hazardous Industrial Environments

FRP strips are very valuable in hazardous industrial spaces because of their anti-slip and electrical insulating properties. They assist in minimizing slips and falls in risky areas like laundries, mining facilities, and chemical plants. They do not conduct electricity, which lowers the risk of electrical shocks. Also, their high strength protects workers by enhancing safety in environments with potentially dangerous situations.

Used in Public Restrooms

FRP strips are frequently used in public restrooms because of their anti-slip and moisture-resistant qualities. They help reduce slip and fall occurrences, which is especially helpful in wet areas. They can endure heavy foot traffic, and their lifespan helps maintain cleanliness and safety in public restrooms, changing areas, and swimming facilities.

Determine the Intended Purpose

Determine the desired use of cement-coated fiberglass strips before getting them. This is so since different FRP strip varieties work best for certain applications. For instance, anti-slip or slip strip flooring is excellent for marine and pool decks where slippage is likely. High-strength, corrosive-resistant strips are excellent for industrial areas with heavy machinery.

Assess Environmental Factors

Evaluate the environment in which the FRP strips will be placed. Humidity, heat, and chemicals are possibly typical environmental factors. These conditions can all deteriorate certain materials. Pick fiberglass strips with coatings or resins that can endure the environmental elements they are surround by for the longest possible life.

Evaluate Load-Bearing Requirements

Consider how much load the FRP plastic strips will have to support. In this case, light-duty strips may be sufficient for residential patios or walkways. However, for commercial or industrial applications where heavy machinery or foot traffic is likely, go for high-strength, thick FRP strips. Checking the manufacturer's specifications and recommendations ensures the strips are suitable for the required load-bearing capacity.

Ensure Safety Features

Safety is typically a key concern when choosing FRP strip lights. Ensure the strips include anti-slip surfaces, primarily if they will be positioned in risky areas like pool decks or industrial sites. FRP strips with visible safety edges also increase safety by increasing visibility in low-light settings. When safety features are included, the possibility of slip and fall accidents reduces significantly.

Consider Aesthetics and Installation Requirements

Think about the aesthetic appeal of the FRP strips and how they will mesh with the current décor of the space. Clear or colored strips can produce appealing finishes. Installation requirements differ, so choose FRP strips, especially if they are to be installed in challenging places. Some come with self-adhesive backs to ease the labor.

Yes, the FRP strip lights are made to withstand such environments. They are made from resin-impregnated fiberglass, which does not corrode like metals. This makes them ideal for outdoor and industrial usage due to their resistance to moisture, chemicals, and salt air.

The FRP strips are excellent for outdoor use because they withstand all weather conditions, moisture, and UV radiation. They offer slip-resistant surfaces for pools, patios, walkways, and other safety outdoor applications. This also helps protect the equipment and improve safety.

An epoxy stripcan easily be installed with a self-adhesive back. Some may require screws or mechanical fasteners, especially in heavy-load or high-traffic environments. Installation is usually straightforward, requiring minimal tools. Proper surface preparation ensures a secure bond for the FRP strips.

The standard feature of all FRP trim strips is slip resistance. They have textured surfaces that hold the feet during wet and dry conditions. This makes them suitable for risky areas such as swimming pools, decks, and industrial facilities, minimizing the risk of slips and falls.

FRP trim completes maintenance is very easy. Wash them regularly with mild detergent and water to prevent dirt and debris from accumulating. Do not use sharp tools or abrasive materials that could damage the strip surface. This will enable the strips to last longer and maintain their safety and structural features.