All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(550 products available)

Front end loader bucket teeth are essential components of heavy machinery used in various industries such as construction, mining, and agriculture. They are designed to improve the digging and loading capabilities of front end loaders. These teeth are crucial for enhancing the overall efficiency and productivity of the equipment.

Front end loader bucket teeth come in a variety of designs to suit different applications. They are typically made from high-quality steel to withstand the rigors of heavy-duty use. The design of the teeth ensures optimal penetration into the material being excavated, allowing for efficient loading and dumping.

The technical specifications of front end loader bucket teeth may include details such as the material composition, hardness rating, dimensions, and compatibility with specific loader models. It is essential to choose teeth that are suitable for the intended use and compatible with the loader to ensure optimal performance.

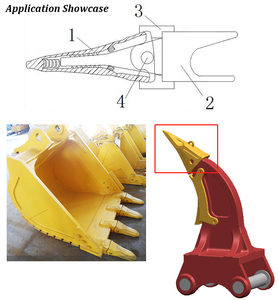

There are several types of front end loader teeth available on the market, each designed for specific purposes. Some common types include standard teeth, rock chisel teeth, tiger teeth, and flare teeth. Each type offers unique advantages depending on the material being handled and the operating conditions.

Standard teeth are versatile and suitable for general-purpose digging and loading tasks. Rock chisel teeth are designed for rocky and abrasive conditions, offering enhanced durability and wear resistance. Tiger teeth feature a more aggressive profile for improved penetration, while flare teeth are ideal for loose or sandy materials.

The features of front end loader bucket teeth contribute to their overall performance and longevity. Features such as self-sharpening profiles, hardened surfaces, and secure locking mechanisms enhance the efficiency and durability of the teeth. These features ensure consistent digging and loading performance, even in challenging environments.

One of the key advantages of high-quality front end loader teeth is their ability to increase the productivity of the equipment by reducing cycle times and minimizing wear and tear on the loader. By choosing the right teeth for the application, operators can optimize the efficiency of their front end loaders and achieve better results.

When selecting front end loader bucket teeth, it is essential to consider factors such as the type of material being handled, the operating conditions, and the desired performance outcomes. Choosing teeth that are compatible with the loader and suitable for the application can significantly impact the efficiency and productivity of the equipment.

Buyers should also pay attention to the quality and reputation of the manufacturer when choosing front end loader teeth. Ensuring that the teeth are made from high-grade materials and manufactured to industry standards can help avoid premature wear and damage, ultimately leading to cost savings and improved operational efficiency.

Proper maintenance and care are essential to prolong the lifespan of front end loader bucket teeth and ensure optimal performance. Regular inspection of the teeth for wear and damage, timely replacement of worn teeth, and proper cleaning and lubrication can help extend the life of the equipment and prevent costly repairs.

Additionally, operators should follow manufacturer guidelines for maintenance and operation to maximize the efficiency and longevity of the front end loader teeth. By implementing a proactive maintenance schedule and addressing issues promptly, businesses can minimize downtime and maximize the return on investment in their equipment.