All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2707 products available)

When it comes to formwork, there are various types that can be customized to suit a particular project. Here are the common types of formwork:

Timber Formwork

This is the most common type of formwork. It's used to create beams, columns, and slabs. It consists of plywood, wooden beams, and fasteners. Timber formwork is reusable, and its construction is easy. It's also customizable and offers a smooth finish. However, it's lightweight and suitable for small projects.

Aluminum Formwork

This formwork is made of aluminum panels. It is lightweight and easy to handle. It is also reusable and offers a high-quality finish. Moreover, it requires minimal labor during assembly and dismantling. This formwork is suitable for projects with repetitive designs. On the flip side, aluminum formwork panels price can be high and are mostly suitable for tall structures.

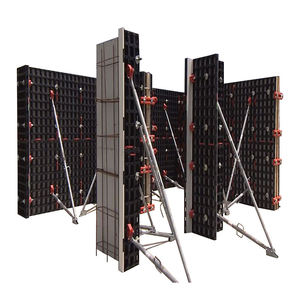

Steel Formwork

As the name suggests, this formwork is made of steel panels. It is durable, strong, and resistant to deformation. Moreover, it can be reused many times and offers a smooth finish. This formwork is suitable for large-scale construction projects. Nonetheless, it requires skilled labor for assembly and dismantling. Its weight makes transportation and handling difficult.

Plastic Formwork

This type of formwork is made of high-quality plastic. It is lightweight, easy to assemble, and dismantle. This formwork is resistant to water, and chemicals, and it can be reused several times. Additionally, it requires low maintenance and is suitable for small-scale projects. However, it offers lower structural support than other formwork types.

Fabric Formwork

Fabric formwork consists of permeable fabric molds. The fabric is tensioned over a framework to create molds of desired shapes and sizes. This formwork is lightweight, flexible, and creates complex shapes. It also allows the passage of water, which can be useful for certain concrete finishes. While this formwork is innovative, it is not widely used due to limited awareness and expertise.

Brick Formwork

This involves using bricks to create formwork for concrete. Brick formwork is strong, durable, and reusable. It also offers excellent insulation and reflects the desired texture on the surface. Nevertheless, it is labor-intensive and time-consuming. Furthermore, it requires skilled labor and is unsuitable for complex shapes and sizes.

Insulated Concrete Formwork (ICF)

These are forms for poured concrete that remain in place after the concrete is set. They are made of rigid foam insulation. ICFs are lightweight and provide excellent insulation. They also create strong and durable structures. Additionally, they are energy-efficient and easy to assemble. Unfortunately, they have a high initial cost and limited reuse potential.

Formwork panels are crucial in the construction industry. Their features and functions are essential for construction projects involving concrete structures. Here are the critical features and functions:

Support Concrete Molding

The primary feature of formwork panels is to provide a mold or shape for casting concrete. Formwork panels are crucial in shaping and supporting concrete structures until they harden and gain strength. Formwork panels are positioned and secured to create the desired shape of the concrete slab, beam, column, or wall.

Load-Bearing Capacity

Formwork panels are designed to withstand various loads without collapsing or deforming. Load-bearing capacity is the ability of the formwork panel to support the weight of wet concrete, reinforcement steel, and external loads like workers and construction equipment. High load-bearing capacity ensures the safety and stability of the formwork during concrete pouring and curing.

Reusable

Many formwork panels are designed for multiple uses, which helps reduce construction costs and waste. Reusability helps reduce construction costs and environmental impact by minimizing the need for new materials. Formwork panels can be made from materials like plywood, steel, and aluminum, which can withstand wear and tear from repeated use.

Easy Assembly and Disassembly

Formwork panels are designed for quick and efficient assembly and disassembly. This allows construction projects to be completed in a timely manner. Features that enhance easy assembly and disassembly include lightweight materials, simple connection systems, and clear instructions.

Concrete Finish Control

Formwork panels control the finish texture and smoothness of the casted concrete. This affects the appearance and performance of the final structure. Some formwork panels have special surface finishes that create decorative patterns on the concrete. Others have a smooth surface that gives the finished concrete a sleek look.

Weather Resistance

Formwork panels resist harsh weather elements like wind, moisture, and UV rays. Weather resistance ensures the integrity of the formwork and the quality of the concrete. Some formwork panels have coatings or treatments that enhance their durability.

Customization

Formwork panels can be customized to meet specific project requirements. Customization involves adjusting the size, shape, and structural design. This ensures the formwork panels are suitable for different types of concrete structures.

Formwork panels are used in various construction scenarios to support and shape wet concrete during its curing process. Here are some common usage scenarios:

Concrete Slabs

Formwork panels are extensively used in constructing concrete slabs for buildings, parking garages, bridges, and other structures. They help achieve flat and smooth surfaces for residential and commercial properties.

Concrete Walls

Formwork panels are also used to create concrete walls for foundations, basements, and structural walls in buildings. They help achieve a strong, durable, and aesthetically pleasing wall surface.

Concrete Beams and Columns

Formwork panels are used to shape concrete beams and columns that support the structural integrity of a building. They help create strong and stable structural components that can bear heavy loads.

Bridges and Overpasses

Formwork panels are used in constructing bridges and overpasses to create concrete beams, decks, and abutments. They help create strong and durable structures that can withstand heavy traffic and environmental conditions.

Parking Garages

Formwork panels are commonly used in constructing parking garages to create concrete slabs and walls. They help create strong and stable structures that can support heavy vehicles and traffic.

Tunnels and Underground Structures

Formwork panels are used in constructing tunnels and underground structures to create concrete arches and walls. They help create strong and stable structures that can withstand high pressure and environmental conditions.

Residential and Commercial Construction

Formwork panels are used in residential and commercial construction projects, including houses, apartment buildings, office buildings, and warehouses. They help create strong and durable concrete structures with smooth and aesthetically pleasing surfaces.

Retaining Walls

Formwork panels are used in constructing retaining walls to hold back soil and water. They help create strong and stable walls that can withstand high pressure and environmental conditions.

Type of formwork

Each type of formwork has its unique features and applications. Therefore, it is essential to consider the intended use before buying. For instance, the plastic formwork is ideal for constructing walls, foundations, and slabs. At the same time, tunnel formwork is suitable for repetitive construction of structures like buildings.

Quality and durability

The quality of construction formwork panels directly affects the project budget and timeline. It is wise to choose high-quality panels that are durable and robust to withstand pressure from concrete. Even though they are more expensive, they are reusable and can provide a seamless finish to the project. As such, it eliminates the need to hire formwork panels, which can be costly in the long run.

Panel price

Not all formwork panels are priced the same. Therefore, it is essential to consider the price before making any purchase. This entails balancing between the cost and quality of the panels. Although some panel types are more affordable, they may not be as durable or offer a concrete finish. On the other hand, the expensive ones tend to have higher quality and are reusable.

Supplier's reputation

The construction business owner should take time to research and read online reviews to find a reputable supplier. A good supplier will provide high-quality formwork panels, excellent customer service, and timely delivery. They will also offer competitive prices and be willing to negotiate, especially on bulk orders.

Support and service

Excellent customer service is critical in any business. Therefore, it is prudent to select a formwork panels supplier who has a dedicated support team. More importantly, the team should be knowledgeable and available 24/7 to answer questions and offer assistance when needed. This will ensure smooth communication and timely resolution of any issues that may arise before and after the sale.

Q1: What are formwork panels?

A1: Formwork panels are temporary structures or molds used in construction to shape and support concrete until it sets and hardens. They provide the desired shape, size, and finish for concrete elements such as walls, slabs, beams, and columns.

Q2: What is the purpose of formwork panels?

A2: The purpose of formwork panels is to hold freshly poured concrete in the desired shape until the concrete cures and gains enough strength to support itself. Formwork panels also influence the final surface texture and finish of the concrete.

Q3: What are the types of formwork panels?

A3: There are several types of formwork panels, including:

1. Plywood formwork panels - made of wood and used for casting concrete structures.

2. Steel formwork panels - durable, reusable panels made of steel.

3. Aluminum formwork panels - lightweight and easy to handle.

4. Plastic formwork panels - made of high-quality plastic materials. They are lightweight, reusable, and resistant to weather elements. They are mainly used for small-scale construction projects.

5. Fabric formwork panels - flexible molds made from fabric materials. They create textured concrete finishes and are used for architectural features.

Q4: What are the key factors to consider when purchasing formwork panels?

A4: Some of the key factors to consider when purchasing formwork panels include:

Durability - choose formwork panels constructed with durable materials that can withstand multiple concrete pours.

Reusability - consider the number of times the formwork panels can be used to reduce overall construction costs.

Weight - the weight of the formwork panels affects their ease of handling and transportation.

Construction project size - consider the size and scale of the construction project to determine the appropriate type and quantity of formwork panels needed.

Surface finish requirements - the type of formwork panel used influences the final surface finish of the cured concrete.