All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(934 products available)

There are several different types of formula of gypsum. Each type is used for a specific purpose. Here are the various types of gypsum:

Natural Gypsum

Natural gypsum is a mineral that consists of hydrated calcium sulfate. It is found in sedimentary rock formations and has a chemical formula of CaSO4·2H2O. The crystal structure of natural gypsum is monoclinic, and it usually appears in white to colorless, transparent to translucent, and massive or fibrous forms. Its hardness ranges from 1.5 to 2 on the Mohs scale, and its density varies between 2.3 to 2.4 grams per cubic centimeter.

Plaster of Paris

Plaster of Paris is a quick-setting material made from gypsum. It has a chemical formula of CaSO4·0.5H2O. When mixed with water, it rehydrates and sets solidly. Plaster of Paris is often used for casting molds, sculptures, and even surgical bandages. It is lightweight and can be easily shaped when wet.

Gypsum Board

Gypsum board, also known as drywall or plasterboard, consists of a layer of gypsum sandwiched between two sheets of strong paper. It has a chemical formula similar to that of natural gypsum. Gypsum board is commonly used for interior wall and ceiling finishes. It is fire resistant and provides good sound insulation.

Gypsum Cement

Gypsum cement is a building material used to make durable casts and molds. It contains a higher percentage of gypsum than plaster of Paris. Gypsum cement has a chemical formula similar to that of plaster of Paris. It can be molded into intricate designs and used for ornamental trim in homes.

Gypsum Wallboard

Gypsum wallboard is another name for gypsum board. It is widely used as a finishing material for walls and ceilings. Gypsum wallboard has a chemical formula similar to that of natural gypsum. It comes in various sizes and thicknesses to suit different construction needs.

Gypsum Blocks

Gypsum blocks are precast units made from partially hydrated gypsum. They have a chemical formula similar to that of natural gypsum. Gypsum blocks are used for non-load-bearing walls and partitions. They offer good fire resistance and thermal insulation properties.

When selecting gypsum products, it is vital to consider the end use. Each type of gypsum will meet specific requirements, whether it is used for construction, medical imaging, or as a soil amendment.

Purity and Quality:

Gypsum comes in various purity levels depending on the end use. For agricultural use, a lower grade gypsum is acceptable. However, if using gypsum for food or pharmaceutical applications, opt for food-grade or pharmaceutical-grade gypsum to meet strict quality and safety standards.

Particle Size:

The particle size of gypsum affects its solubility and, thus, its effectiveness in various applications. Finer particles dissolve more quickly and are better for applications like plaster, wallboard, or rapid soil amendment where quick action is desired. Coarser particles release more slowly, which benefits applications like controlled-release fertilizers or long-term soil conditioning.

Availability:

Consider the local availability of gypsum products. Some regions may have easy access to natural gypsum, while others have more anhydrite. Transportation costs and availability can impact the overall cost of the gypsum.

Environmental Considerations:

Consider the environmental impact of the gypsum product. Some gypsum is mined using environmentally invasive methods. Look for sustainably sourced gypsum whenever possible. Additionally, consider the product's carbon footprint concerning transportation and processing.

Cost:

The cost of gypsum varies depending on the type and quality. Consider the price per unit weight and the required amount for the specific application. For large-scale uses, like construction, the cost will significantly impact the overall project budget.

Regulatory Requirements:

Some applications require gypsum to meet certain regulatory standards. This is especially important for food and pharmaceutical applications. Check the necessary requirements and purchase adequately processed gypsum.

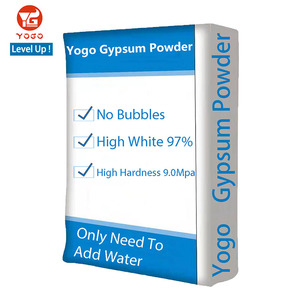

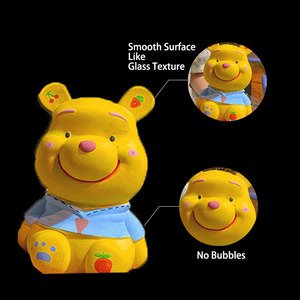

The most common way of using gypsum is by mixing the powder with water. It has a quick setting time, making it easy to work with. To mix, one has to pour the desired amount of powder and then add water slowly. The mixture will form a smooth paste that can be used for molding, casting, or coating applications. It is essential to work quickly since it will harden fast.

For construction purposes, workers place gypsum boards on walls and ceilings. They use screws or nails to fasten the boards to the framing members. The joints are then finished by applying joint compound gypsum and tape to create a smooth surface. Once the finishing is done, the boards can be painted.

For horticultural applications, gypsum is spread on the soil. It is then tilled or worked to improve the soil structure. The amendment helps to reduce soil compaction and enhance root growth. It is also used to add calcium and sulfur nutrients. It is a preferred soil conditioner because it does not drastically change the soil's pH level.

When using gypsum, especially in powder form, it is essential to wear a dust mask and respirator. The dust can irritate the lungs. It is also vital to put on gloves and goggles to protect oneself from skin and eye irritation. Working in a well-ventilated area reduces the accumulation of dust and exposure. In case of ingestion, seek medical help immediately. Some of the symptoms may include nausea, vomiting, and diarrhea.

Gypsum serves various functions in medicine, agriculture, and construction:

Plaster cast

When mixed with water, the gypsum powder hardens into a solid mass. The solid mass can be molded into any shape. This property makes it an excellent material for making plaster casts for broken bones.

Soil conditioner

Gypsum improves soil quality by adding calcium and sulfur, which are essential nutrients for plant growth. It also reduces soil compaction, making it easier for plants to grow.

Drywall

Gypsum board is fire-resistant and provides excellent insulation for buildings. It is an essential material used in constructing interior walls and ceilings.

Some features of gypsum include:

Availability of nutrients

Gypsum contains essential nutrients like calcium and sulfur that benefit plants and human bones.

Ease of application

Gypsum is easy to apply in various fields, from agriculture to construction. It can be easily mixed with water, soil, or other construction materials.

Cost-effective

Gypsum is a natural product that is readily available. This feature makes it a cheap option for plaster casts, soil conditioners, and construction materials.

Non-toxic

Gypsum is a non-toxic and safe material that can be used in various applications without health risks.

Gypsum can be designed in different forms for various applications. When used as a powder, it is mixed with water to form molds or plaster casts. For construction materials like drywall and plaster, the gypsum is molded into sheets and boards to fit different construction needs. Gypsum used in agriculture is packaged in bags or pellets for easy application.

Q1: What is the chemical formula for gypsum?

A1: The chemical formula of gypsum is CaSO4·2H2O.

Q2: What is the molar mass of gypsum?

A2: The molar mass of gypsum is 172.17 g/mol.

Q3: What are the main elements in gypsum?

A3: The main elements in gypsum are calcium (Ca), sulfur (S), and oxygen (O).

Q4: What is the pH of gypsum?

A4: The pH of gypsum is approximately 7, which makes it neutral.

Q5: Does gypsum contain silica?

A5: Gypsum does not contain silica. Silica has a different chemical formula (SiO2).

Q6: What is the density of gypsum?

A6: The density of gypsum ranges from 2.3 to 2.4 g/cm3.