All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1294 products available)

Flexible elastomeric foam insulation is a thermal insulation material made from synthetic rubber, specifically designed for applications requiring flexibility, lightweight, and effective insulation. It is widely used in HVAC (Heating, Ventilation, and Air Conditioning) systems, plumbing, electrical, and automotive industries. There are different types of flexible elastomeric foam insulation, including:

Uncross-linked and Non-vulcanized Foams:

This type of foam is characterized by a lack of cross-linking between the polymer chains. As a result, it forms a non-vulcanized and uncross-linked flexible elastomeric foam. The absence of cross-linking leads to a more open-cell structure. As a result, it exhibits higher permeability to gases and liquids. Additionally, it has lower mechanical strength and thermal stability.

Cross-linked and Vulcanized Foams:

These flexible elastomeric foam insulations are created through a chemical process known as vulcanization. It involves cross-linking the polymer chains using heat and sulfur or other curing agents. The process results in a network structure that enhances durability, mechanical strength, and thermal stability. This foam insulation exhibits low thermal conductivity, high elasticity, and excellent resistance to aging and environmental factors. It is commonly used in applications requiring high-performance insulation, such as HVAC systems, refrigeration, and automotive components.

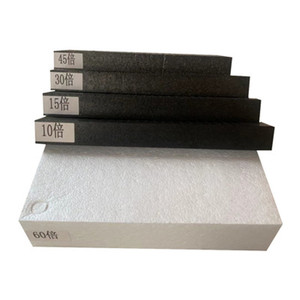

Closed-cell Foams:

This type of flexible elastomeric foam insulation is characterized by its structure. For instance, it has a high proportion of closed cells filled with gas or air. The closed-cell structure gives it superior thermal insulation properties. Also, it provides excellent resistance to moisture permeability and vapor transmission. Due to these characteristics, it is widely used in applications requiring high insulation efficiency and moisture control. For example, in refrigeration, pipeline insulation, and exterior wall applications.

Open-cell Foams:

These flexible elastomeric foam insulations have a structure that is predominantly composed of interconnected open cells. This results in lower density, higher breathability, and improved sound absorption properties. Open-cell foams are generally more flexible and lighter than closed-cell foams. They are primarily used in applications where moisture control and thermal insulation are more important than water resistance. For example, in interior wall insulation and soundproofing.

Thermal Resistance:

Flexible elastomeric foam insulation is designed with an exceptional low thermal conductivity. This feature provides the foam with excellent thermal performance. Its closed-cell structure minimizes heat transfer through conduction, making it an ideal choice for applications where temperature control is critical. Such applications include refrigeration, air conditioning and piping systems.

Moisture Resistance:

This type of insulation foam is highly resistant to water vapor penetration. Its closed-cell structure and materials provide it with this ability. Moisture resistance is important because it prevents condensation and inhibits the growth of mold and mildew. Flexible elastomeric foam insulation is suitable for humid and high-moisture environments. It protects structures and systems from water-related damage.

Flexibility:

As the name suggests, this insulation foam is highly flexible. Its design allows it to be easily bent and adapted to different shapes and sizes. This feature enables it to be used on irregular surfaces and complex geometries. Examples of such surfaces are ducts and pipes. Its flexibility ensures a continuous and efficient insulation system, thus minimizing thermal bridging.

Mechanical Strength:

This type of insulation foam offers excellent mechanical strength. Its closed-cell structure enhances its durability and resilience. This foam can withstand compressive and tensile forces without damage or significant degradation. Its mechanical strength extends the lifespan of systems and insulated structures. It also provides structural integrity to insulated systems.

Fire Resistance:

Flexible elastomeric foam insulation is designed with specific fire-resistant additives. These materials delay ignition and reduce the spread of flames when exposed to fire. The fire resistance characteristic enhances the safety of insulated structures and systems. It complies with building codes and industry standards that require certain levels of fire resistance in insulation materials.

Lightweight:

This insulation foam is lightweight. Its closed-cell structure traps air or other blowing agents, reducing the overall weight. Its lightweight nature facilitates easier handling and transportation. The flexibility foam insulation is applied in sheets or rolls, providing continuous insulation with minimal joints and seams.

Building Insulation:

Elastomeric foam can be used on buildings to keep the temperature inside comfortable. It is used in the walls, roofs, and ceilings of commercial and residential places. This foam helps to lower energy costs by keeping the heat or cool air from going outside.

Pipes and Ducts:

These flexible elastomeric foam insulations are mostly used on pipes and ducts that carry air and fluids in buildings. When applied to these surfaces, it minimizes energy loss, ensuring that the air and fluids maintain their intended temperatures. Also, it helps reduce condensation and keeps it from dripping on pipes or ducts.

HVAC Systems:

Insulation elastomeric foams are used in heating, cooling, and ventilating systems. It's because it has a low thermal conductivity, which allows for the efficient transfer of air. This helps reduce energy costs. Also, its flexibility allows it to be used on different HVAC components like ducts, pipes, and storage tanks.

Refrigeration:

These flexible elastomeric foam insulations are very important in refrigeration systems. Insulation foams ensure that cold air or refrigerant is distributed efficiently by preventing heat transfer from the outside to the inside. This is important for perishable goods that require a cool environment to stay fresh. Additionally, it helps reduce the formation of frost and ensures the system runs smoothly.

Industrial Applications:

Flexible elastomeric foam insulation is used in industrial settings. It insulates pipes, tanks, and machinery that operate at high temperatures. This allows it to function efficiently and protects against heat or cold. Additionally, it protects workers from touching hot or cold surfaces that can cause injuries.

Automotive Applications:

These flexible elastomeric foam insulations are used in car manufacturing. It is used to insulate the engine compartment, exhaust systems, and other automotive components. This is because it is lightweight, which is important in vehicle design. Also, it helps reduce heat transfer and keep critical components at the desired temperature.

When choosing flexible elastomeric foam insulation, it is essential to consider several factors to ensure the selected product meets specific needs and requirements. Here are some crucial elements that should be taken into account:

Application

Consider the application of the insulation material. If the insulation is needed for pipes, ducts, or HVAC components, flexible elastomeric foam insulation would be an excellent choice due to its flexibility and ease of installation. However, if the insulation is required for different applications, such as walls, roofs, or floors, other types of insulation may be more suitable.

Climate

The climate of the area should also be considered when choosing insulation material. If the area experiences extreme temperatures, a material with a high R-value, such as fiberglass or foam board insulation, may be more effective. However, flexible elastomeric foam insulation is suitable for moderate climates due to its excellent thermal properties.

Moisture

Consider the moisture levels in the area where the insulation will be installed. Flexible elastomeric foam insulation is resistant to moisture and is suitable for areas with high humidity levels, such as bathrooms, kitchens, and basements. Other insulation materials, such as cellulose or fiberglass, may be more suitable in drier areas.

Installation

Flexible elastomeric foam insulation is easy to install and requires minimal tools and equipment. However, other types of insulation may be more effective if the insulation is to be installed in hard-to-reach areas or complex shapes. Consider the installation process and choose an insulation material that is easy to install and cost-effective.

Cost

The cost of the insulation material should also be considered when making a choice. Flexible elastomeric foam insulation is more expensive than other types of insulation. However, it offers numerous benefits, such as excellent thermal and moisture resistance, which can save energy costs in the long run. Consider the upfront costs and long-term benefits of each insulation material and choose the one that fits the budget and requirements.

Q1. Is elastomeric foam flexible?

A1. Yes, elastomeric foam is flexible. Its flexibility allows it to be bent or folded without breaking or cracking. Flexible elastomeric foam insulation is ideal for applications where flexibility is needed, for instance, in insulating pipes and ducts.

Q2. What are the disadvantages of elastomeric foam?

A2. Despite its many advantages, elastomeric foam has some disadvantages. For instance, it has a short lifespan compared to other insulation materials. It also has a low R-value per inch, meaning that thicker materials are needed to achieve the desired thermal resistance. Its cost is also high compared to other insulation materials, such as closed-cell foam.

Q3. What does R-value mean?

A3. The R-value of a material indicates how well it resists heat flow. The higher the R-value, the better the material insulates. Elastomeric foam insulation has a high R-value, making it an excellent insulator.

Q4. How is elastomeric foam made?

A4. Elastomeric foam is made by mixing chemicals to form a foam that is cured into tubes or sheets. The foam is then vulcanized to form a strong, durable, and weather-resistant material.

Q5. What are the applications of elastomeric foam insulation?

A5. Flexible elastomeric foam insulation has numerous applications. For example, it insulates pipes, ducts, and HVAC systems. It is also used in roofing applications, such as flat roofs and exposed ductwork. Additionally, it is used in refrigerated trucks and containers to maintain a consistent internal temperature.