All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4024 products available)

Flanges are used to create a tight joint between pipes and to accommodate pipe fit-ups and the expansion of materials. An edge that is created at right angles to the plane of the material for the purpose of welding is called a flange. There are many types of flanges, including the welding neck flange, which is used when the angle between the flange and pipe needs to be in accordance with a particular requirement. The broad types of flange forming machines can be categorized according to the types of flanges they make:

Machine Power:

A flange-forming machine usually requires a specific power supply to run efficiently. This power is often expressed in kilowatts (kW) or horsepower (HP). The machine's power determines how thick and strong the metal it can work with is. For example, a machine with a higher power rating can handle tougher metal material. This means it can make flanges from very sturdy, heavy metal without any problems.

Flange Forming Modes:

Machines for forming flanges have different ways they can work. Two common methods are hydraulic and mechanical operation. Hydraulic machines use fluid pressure to shape the metal. Mechanical ones rely on electrical motors and gears. Each one has its own benefits, like hydraualics usually handling larger sizes easily.

Mold Types:

To make different styles of metal flanges, machines use various molds or dies. A mold called a punch dies sets the metal into a certain shape when pressed. Another type, splitter dies, cuts the metal to create evenness and accuracy. Each mold allows the flange-forming machine to produce specific, diverse shapes of flanges from the metal.

Machine Size:

Flange forming machines are made in different sizes to accommodate various flange types and dimensions. The size is often denoted as 'Length * Width * Height'. It is also indicated in terms of weight. Larger machines are usually heavier and need more space to set up.

It is also crucial to conduct regular maintenance for the machines to keep them functioning for a long time. Users can consider the following care and maintenance tips:

Flange forming machines are used in manufacturing industries and workshops to make flanges for the end of pipes. They are commonly seen in the following places:

Before ordering flange forming machines in bulk for sale, it's a good idea to consider the following key buying tips:

Industrial-grade build quality

Always choose machines with strong, externally-built frames. A heavy cast iron or steel frame generally has suitable strength. Secondly, order machines with a durable coating. Corrosion, rust, and wear resistance will be improved with the right coating.

Flange forming types

Select machines that can form the flanges demanded by customers. The most popular types are riveted, flanged, cone-shaped, flat, bell or saucer-shaped, and the Flander type. Also, consider whether the die sets need to be customized for other flange types.

Hydraulic vs. manual machines

Decide whether to sell manual or hydraulic machines. Manual machines are less costly and ideal in low-tech workshops. However, they need more physical effort. Hydraulic machines are easier to use, but they cost more. Consider the typical workshop conditions and technicians' skill levels for this decision.

Die Materials

The machine comes with die sets made from different materials. Steel die sets are strong and long-lasting, but they may need extra lubrication. Aluminum die sets need less lubrication but wear out faster. Acetal and nylon are suitable for non-stick materials requiring minimal lubrication or cooling. Decide on the proper die material based on the flange types and materials.

Operator safety

Ensure the machine has safety features such as guards, emergency stop buttons, and overload protection. Check for proper safety instructions in the operator manual. Customer safety is vital, so choose machines with operator safety in mind.

Q1: What are the types of flange forming machines?

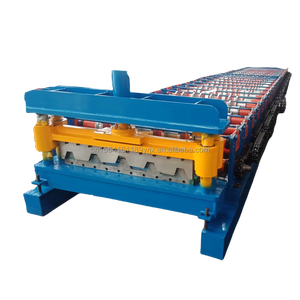

A1: The common types of flange forming machines includes swivel machines, manual flange forming machines or conical machines, hydraulic forming machines, roll forming machines and etc. They have their unique advantages and are fit for different uses.

Q2: Can a flange forming machine form different materials?

A2: The forming machine usually works with metal materials like stainless steel, carbon steel and aluminum.

Q3: Is the flange forming machine compatible with different types of dies?

A3: Yes, the flange forming machines are compatible with various die sets, which allows them to perform diferent machining operations.

Q4: Can a flange forming machine form non-standard flanges?

A2: Yes, many flange forming machines can be custom to form non-standard flanges as needed by specific applications.