All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5258 products available)

Concrete-reinforcing fiberglass bars come in different types. Each type serves a specific purpose. The choice of bars depends on several factors, like the construction environment, the load they will support, and the specific project requirements. Here are the most common types:

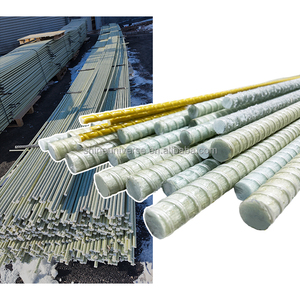

Standard fiberglass bars are made of epoxy resin and glass filaments. The glass filaments inside the bars provide tensile strength. These bars are widely used in many construction projects. This is because they have a combination of lightness and strength.

Corrosion-resistant fiberglass bars are ideal in environments with high exposure to water, chemicals, or salt. These bars are constructed with special resin systems. The resin provides high resistance to corrosive elements.

Corrosion-resistant bars are suitable for marine applications, wastewater treatment facilities, and areas with high humidity. This makes them a reliable choice for long-term durability in adverse conditions.

High-strength fiberglass bars are made for projects that require extra load-bearing capacity. These bars have a higher tensile strength compared to standard fiberglass bars. They are usually made with special fibers or reinforced resin systems.

High-strength bars are common in heavy-traffic areas, industrial constructions, and high-load structural applications. They provide excellent performance in high-stress environments.

Customized fiberglass bars are tailored to meet specific project needs. These can vary in size, shape, resin materials, and fiber orientations, based on requirements. Developers usually have them produced for specialized applications. These include unique structural designs or specific load requirements.

Customization also allows for adjustments in mechanical properties, like flexibility or impact resistance. This is to meet the performance needs of particular environments or uses.

Fiberglass reinforcement rods have several features that make them suitable for various applications. They offer some advantages over steel reinforcement bars. These include high resistance to corrosion and more extended service life.

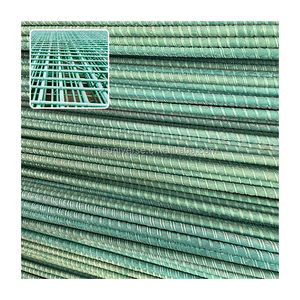

The variety of fiberglass reinforcement bars available ensures developers can find a suitable solution for virtually any concrete-reinforcement technology need. Below are some of the applications:

Fiberglass bars are used to reinforce concrete in many construction projects. These include buildings, bridges, and parking structures. Their resistance to corrosion makes them ideal for both above-ground and underground constructions. This is especially in areas prone to exposure to moisture or chemicals.

Developers in large-scale infrastructure projects, like roads, bridges, and tunnels, use fiberglass bars to extend the lifespan of their structures. The bars provide added strength without increasing the overall weight of the structure. Thus simplifying handling and installation.

Farm developers in agricultural settings that involve irrigation channels or drainage systems also go for fiberglass bars. The bars are used to construct durable foundations, water channels, and drainage systems. Their resistance to soil-related chemicals ensures long-term stability.

Fiberglass bars are preferred in marine construction. Things like docks, piers, and seawalls usually have saltwater exposure. Corrosion-resistant fiberglass bars are ideal for these applications. They can withstand the harsh marine environment while providing the necessary strength.

Industrial constructions with floors, pavements, or structures exposed to heavy loads, chemicals, or moisture also benefit from fiberglass rods. The bars are used in manufacturing plants, warehouses, and chemical facilities. Their ability to resist corrosion and wear makes them a reliable choice for long-term performance in these high-demand environments.

Developers who need to create precast concrete elements like slabs, wall panels, and beams, also use fiberglass bars to enhance their strength and durability. The bars are easily integrated into various precast components. This improves their performance in a variety of settings.

Fiberglass bars are normally selected based on several factors to ensure they meet the performance requirements of specific projects. Here are the key considerations to keep in mind:

Developers should first consider the specific requirements of the project at hand. Things like load-bearing capacity, environmental conditions, and the expected lifespan of the structure should be taken into account. Doing this ensures the fiberglass bars provide adequate reinforcement.

Fiberglass bars are available in various profiles. Each type is suited for distinct applications. Developers should choose between pultruded profiles or standard bars based on their durability, cost, and ease of handling. Those with special customizations also provide added advantages for specialized applications.

Buyers should prioritize fiberglass bars manufactured with corrosion-resistant properties. These bars typically include a higher concentration of chemical-resistant glass fibers. They are best for projects in high-corrosive environments, like marine, industrial, or chemical processing facilities.

It’s essential to consider the load capacity of the fiberglass bars. Buyers who work on heavy-load or high-stress projects should opt for those bars with enhanced load-bearing capacity. These bars are usually manufactured with additional reinforcement or specific resin formulations.

Choose fiberglass bars developed with quality materials and manufacturing processes. Buyers should work with suppliers whose bars have uniform strength and diameter. This ensures consistent performance throughout the structure. Users should also check for standard certifications to indicate fiberglass bars meet industry requirements.

Cost is a critical factor when making any purchase. Buyers should get fiberglass bars at suppliers’ bulk prices and weigh the cost against the long-term benefits the bars offer. These include reduced maintenance and increased durability.

Buyers should select fiberglass reinforcement bar suppliers with a solid reputation in the industry. They should ensure the supplier can consistently provide high-quality products.

Fiberglass bars are made by weaving thin glass strands into a solid, long cylindrical shape. The shape is then strengthened by a thick epoxy resin coating. This makes the bars lightweight yet exceedingly strong.

Yes, fiberglass rebars are good for concrete. They provide tension support, helping the concrete withstand heavy loads. They are ideal for high-strength applications. These include bridge deck slabs and prefabricated concrete products.

The only major disadvantage of fiberglass bars is that they are more expensive than steel bars. Additionally, while they flex under high temperatures, this is actually an advantage. It allows the structure to expand and contract without cracking or breaking.

Yes, fiberglass rebars are certainly worth it. Their anti-corrosive properties outperform steel bars because they do not weather, rust, or corrode. This makes fiberglass rebars a long-lasting alternative in difficult conditions. They are also much lighter in weight, which allows for quicker installation and transport.