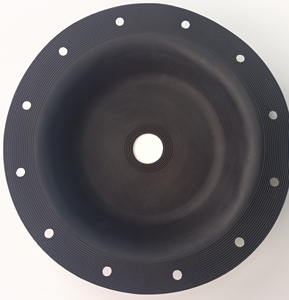

Introduction to Fabric Diaphragms Rubber

Fabric diaphragms rubber are crucial components used in various industrial applications, known for their durability, flexibility, and reliability. These diaphragms serve as barriers or membranes in numerous systems, providing essential functions such as pressure regulation, fluid control, and shock absorption. The incorporation of fabric in rubber diaphragms enhances their characteristics, making them suitable for demanding conditions where conventional materials might fail. Understanding their types, features, and applications can significantly improve operational efficiency in various industries.

Types of Fabric Diaphragms Rubber

- Single-Layer Fabric Diaphragms: These are made from a single layer of rubber-coated fabric, offering basic functionality and cost-efficiency.

- Multi-Layered Fabric Diaphragms: Constructed with several layers, these diaphragms provide enhanced strength and resistance to wear, suitable for high-pressure applications.

- Reinforced Fabric Diaphragms: Featuring additional reinforcement such as metal or plastic, these diaphragms are designed for extreme environments and demanding operational conditions.

- Specialized Rubber Diaphragms: Tailored for specific applications, these diaphragms may include chemical-resistant or temperature-resistant properties depending on the industry needs.

Function and Feature of Fabric Diaphragms Rubber

- Pressure Regulation: Fabric diaphragms rubber effectively manage pressure levels in hydraulic and pneumatic systems, ensuring consistent operation.

- Fluid Control: They act as seals that prevent leakage while allowing controlled flow in pumps and valves.

- Shock Absorption: These diaphragms help in minimizing vibrations, reducing wear and tear on machinery.

- Flexibility and Durability: Made from high-quality rubber materials and reinforced with fabric, they withstand harsh environments without compromising performance.

Applications of Fabric Diaphragms Rubber

- Aerospace: Utilized in fuel systems and hydraulic controls, fabric diaphragms rubber provide the necessary reliability in aviation components.

- Automotive Industry: Found in brake systems and suspension components, ensuring safe and efficient vehicle operation.

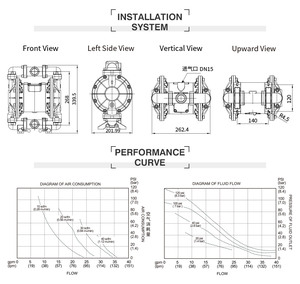

- Industrial Equipment: Used in various machinery for fluid transfer and pressure control, contributing to operational longevity.

- Medical Devices: Essential in devices that require precise fluid management, such as pumps and respiratory equipment.

Advantages of Fabric Diaphragms Rubber

- High Resistance: These diaphragms resist various environmental factors including chemicals, oils, and temperature fluctuations.

- Customizability: They can be tailored to fit specific operational needs, enhancing their functionality across diverse applications.

- Cost-Effectiveness: Offers an attractive balance between initial investment and long-term durability, reducing maintenance costs.

- Enhanced Performance: Improved flexibility and strength lead to better performance in critical applications, ensuring reliability.