Understanding Encoder Values

Encoder values play a crucial role in various applications ranging from robotics to industrial automation. They are essential for translating physical movement into electrical signals that can be understood by machines, computers, and control systems. By accurately capturing positional information, encoder values help improve precision and efficiency across diverse sectors.

Types of Encoder Values

- Incremental Encoders: These encoders measure the change in position and generate pulses as the shaft turns. The output from incremental encoders is relative to a starting point.

- Absolute Encoders: These provide a unique value for every possible position of the shaft. Each position corresponds to a specific binary code, ensuring that even after power loss, the system knows its exact position.

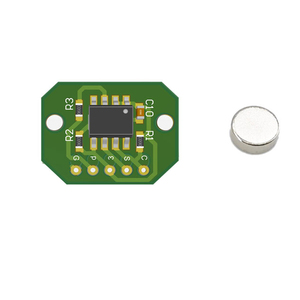

- Rotary Encoders: Designed for rotating parts, these encoders translate angular movement into digital signals, making them ideal for motors and industrial machinery.

- Linear Encoders: These provide position information along a straight line instead of rotational movement, suitable for applications like CNC machines and precision measuring tools.

Function and Feature of Encoder Values

- High Precision: Encoder values ensure accurate position tracking, significantly enhancing the precision of machinery and robotics.

- Durability: Most encoders can withstand harsh environments, making them reliable for long-term usage.

- Real-Time Feedback: Encoder values provide immediate data about position, speed, and direction, enabling prompt adjustments in mechanical systems.

- Flexibility: They can be used in a wide range of applications, including automotive systems, packaging equipment, and conveyor systems.

Applications of Encoder Values

- Robotics: Encoder values are essential in enabling precise movement in robotic arms and autonomous machines.

- Industrial Automation: Many machines utilize encoders for automated tasks, ensuring smooth operation and maximizing efficiency.

- CNC Machining: The high accuracy of encoder values is crucial for CNC machines that require precise positioning of cutting tools.

- Consumer Electronics: Encoders are found in various devices, such as joysticks and gaming controllers, to track movements accurately.

Advantages of Using Encoder Values

- Enhanced Control: Integration of encoder values allows for better control of machinery, leading to improved performance and productivity.

- Reduced Downtime: Accurate monitoring of equipment through encoder values can help in early detection of issues, minimizing unexpected breakdowns.

- Cost-Effective Solutions: Implementing encoder values can provide significant returns on investment by reducing waste and optimizing processes.

- Ease of Integration: Encoder values can be easily incorporated into existing systems, allowing for quick upgrades and enhancements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4