All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(838 products available)

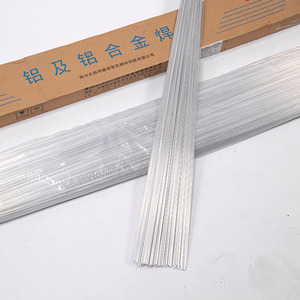

There are several types of aluminum alloys based on their specific compositions, properties, and application suitability. Here's a breakdown of the key differences and uses for each of these alloys:

EN AW-6060

The 6060 aluminum alloy is similar to the 6063 but contains more silicon, which enhances extrusion. It maintains good formability but reduces corrosion resistance. Here are its key characteristics:

EN AW-6061

EN AW-6061 is a versatile heat-treatable alloy, part of the 6000 series, identified for outstanding corrosion resistance and weldability. It combines moderate strength with good machinability, making it one of the most commonly used aluminum alloys in various industries.

EN AW-6063

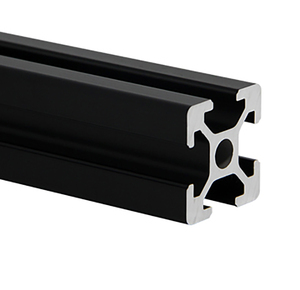

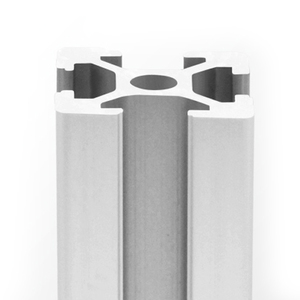

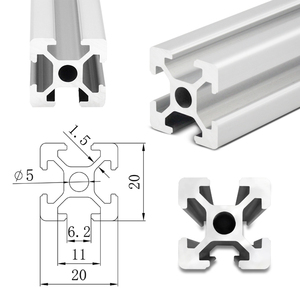

ENG AW-6063 is an aluminum alloy often dubbed “the architectural alloy.” It is well known for its excellent extrusion, forming, and finishing properties. Here are some of its characteristics:

The choice among EN AW-6060, EN AW-6061, and EN AW-6063 aluminum alloys depends on the specific requirements of a project or application. Here's a comparison based on key factors:

Strength and Heat Treatability

The 6061 alloy is the strongest of the three, with its heat treatment enhancing its strength for demanding structural uses. While 6063 offers decent strength for most architectural framework applications, it is relatively weaker than 6061.

Extrusion and Fabrication Ease

The 6063 alloy is the easiest to extrude among these, thanks to its balanced silicon-magnesium composition. It forms complex shapes with superb surface finishes. The 6060 alloy, while also extrudable, is less commonly used due to its moderate-strength profile.

Corrosion Resistance and Anodizing

Both the 6061 and 6063 alloys resist corrosion, but 6063 has superior anodization properties. This makes 6063 ideal for outdoor use and marine applications, where extended surface protection is essential. The anodization further enhances the corrosion resistance exhibited by the 6061.

Appearance and Surface Finishing

While all three alloys can be finished and anodized, 6063 is particularly prized in the construction industry for its aesthetic quality. The alloy forms a smooth finish that is easily anodized for a durable, attractive surface. This renders it suitable for architectural and decorative applications.

Cost and Availability

Availability often depends on local suppliers, but generally, 6060 is slightly less readily available than 6061 or 6063 due to its niche use. The common availability of 6061 and 6063 often translates into comparatively cheaper costs for large-volume projects.

Here is a guide to the typical specifications and maintenance considerations for EN AW-6060, 6061, and 6063 aluminum alloys:

EN AW-6060

Commonly used for architectural components and frames, it has typical mechanical properties of 276 MPa yield strength and 214 MPa ultimate tensile strength with up to 8% elongation. It typically has an anodized thickness of 10μm to 20μm.

EN AW-6061

This alloy is one of the most versatile. Commonly used for truck bodies and marine structures, its typical mechanical properties when heat-treated are up to 310 MPa yield strength and 260 MPa ultimate tensile strength with 15% elongation. Typical anodized coating thickness is 15μm to 25μm.

EN AW-6063

This alloy is frequently used for building sections, window frames, and other architectural applications. Its typical mechanical properties are 198 MPa yield strength and 215 MPa ultimate tensile strength, with 10% elongation. Its typical anodized film thickness is 15μm to 25μm.

There are several crucial factors buyers will need to consider in choosing between EN AW-6060, EN AW-6061, and EN AW-6063 aluminum alloys based on their specific needs. The following factors will influence the choice:

Supplier Reputation and Certification

It is essential to deal with reputable suppliers that are certified to supply materials that meet the required industry standards. An extensive range and quick lead time also count. Suppliers certified for quality can reduce the risk of defective materials and ensure prompt, reliable supply.

Specific Industry Needs

The choice of aluminum alloy depends on the demands of the industry in which it will be used. For construction and architecture, 6063 is usually preferred for its formability and surface finish. For automotive and aerospace applications, 6061 is sought because of its strength and corrosion resistance.

Alloy Availability

Shop for stock. Demand in the local market and existing projects drive the alloy choice. Where stock availability is a challenge, it may be worthwhile to compromise on the alloy of preference and have a workable solution for the project instead.

Custom Extrusions

There may be a need for custom shapes or profiles, based on specific project requirements. For complex extrusions with smooth finishes, the supply of 6063 is preferred over the 6060 and 6061. Discuss available tooling and lead times with the supplier if this is a factor.

Cost Factors

Pricing between different alloys varies, typically based on market prices and alloy characteristics. In general, 6061 is usually pricier due to its mechanical properties. Establish purchasing costs as part of the overall project budget in deciding on an alloy.

The primary factors that influence the choice for a project are the mechanical properties of each alloy, the project requirements, and predominant environmental conditions. Additional factors that come into play are available stock and budgetary considerations.

Engineering Aluminium alloy 6061 is commonly applied in truck bodies, marine parts, and architectural structures. Other areas of application include auto parts, aerospace components, and industrial machinery. It is also widely used in structural applications where high strength and durability are crucial.

Yes. The anodized layer acts as a protective coating that increases corrosion resistance to environmental factors such as moisture and salt. This makes it ideal for outdoor and marine applications.

Its excellent extrusion properties and superior surface finish make it the alloy of choice in architectural applications. It allows for the fabrication of complex designs while maintaining structural integrity.

While both are part of the 6000 series, 6060 is slightly weaker. 6061 has greater strength due to its enhanced magnesium content, making it more suitable for high-stress applications.

Aluminum alloys should be kept dry and cool and out of direct sunlight and moisture. Use protective covers to avoid scratches and markings on the alloy surface during the storage period.

Yes. All aluminum alloys, including the 6060, 6061, and 6063, are 100% recyclable. Recycling helps conserve energy resources and still gives the metal properties needed for high performance.