All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1358 products available)

Emery grinding disks are manufactured in variegated types. Here’s a rundown:

Flap Discs

The design of flap sanding discs incorporates multiple layers of abrasive sheets, akin to a flap, which are affixed to a base disc. These disks are renowned for their adeptness in grinding and blending surfaces paralleling their remarkable flexibility. Furthermore, they contrive to adjust to irregular surfaces effortlessly, which makes them suitable for diverse applications. Flap discs, distinguishably the flap disc 60 grit and finer grits, are advantageous for tasks, including eradicating welds, smoothing sharp edges, and executing a polished finish on metal surfaces. Thus, they are an essential tool in metalworking and construction fields.

Ceramic Discs

Ceramic discs are in high demand particularly in heavy-duty applications. This is due to their stellar performance in tackling stubborn materials like stainless steel and high-carbon alloys. The incorporation of nanotechnology in grain creation promotes superior self-sharpening properties resulting in a consistently sharp edge throughout the life of the disk. Therefore, it makes a ceramic sanding disc a long-lasting and reliable option for industries requiring efficiency and extended wear. In construction, metalworking, and automotive industries, these discs have become an indispensable part of the toolbox.

Zirconia Discs

Zirconia discs are designed for heavy-duty grinding tasks owing to their strength and durability. These discs are ideal for rough grinding and stock removal on metals and other hard materials. Compared to aluminum oxide, zirconia, which is tough and durable, is more durable. Thus, making zirconia discs suitable for industrial applications where materials require quick and effortless shaping. Their resilience under high-pressure conditions and extended lifespan affirms their value in metal fabrication and sanding in construction, making them a staple input in manufacturing.

Aluminum Oxide Discs

Aluminum oxide discs are among the most commonly applied grinding and sanding tools. Their versatility makes them suitable for variegated types of materials ranging from metals to woods. These discs are fabricated with a fine balance between durability and sharpness. Therefore, it makes them ideal for both stock removal and finishing tasks. In addition, premium-quality aluminum oxide disks, like Amazon sanding discs, offer long-lasting performance decreasing the frequency of replacements in maintenance and construction industries.

Grinding Discs

Grinding discs are designed to perform aggressive material removal. Constructed from durable materials like aluminum oxide or silicon carbide, these discs are utilized on variegated surfaces such as metal, stone, and concrete. Grinding discs come in assorted grits. Low grit numbers are suitable for heavy cutting, whereas high grit numbers are intended for fine finishing. Their robust construction enables them to endure strenuous working conditions, guaranteeing efficacy in industrial applications and construction projects alike.

Picking the ideal grinding disc for drill can be rather daunting. Here are some factors wholesale buyers should consider:

Grit Size

Selecting the correct grit size on an emery grinding disk greatly influences the outcome of the task in question. Lower grits, like 40 or 60, are suitable for tasks like stock removing or shaping materials. Higher grits, especially above 100, come in handy for fine sanding that produces a smooth finish. Therefore, understanding the nature of the task at hand will assist in choosing the suitable grit size that meets the needs of various projects.

Material Compatibility

Variegated emery grinding disks are compatible with distinct materials. Therefore, knowing the material being worked on will facilitate the selection of the appropriate disk type. For instance, zirconia and ceramic disks are suitable for hard metals. At the same time, aluminum oxide disks perform optimally on softer materials like brass and woods. Using a disk that is compatible with the material ensures efficient performance and minimizes the likelihood of damage to both the workpiece and the disk.

Bond Type

Emery grinding disks are designed with different types of bonds. That is, they are either resin or rubber bonded. Resin bonds are suitable for aggressive grinding since they provide a rigid hold on the abrasive particles. Conversely, rubber bonds are flexible and ideal for contouring applications. So, choosing the suitable bond type relative to the task influences the disk's performance and longevity. A disk with an appropriate bond type for the application at hand will yield better results in terms of efficiency and surface quality.

Safety Features

Safety remains a key consideration when purchasing emery grinding disks. Such a feature as a reinforced layer helps in preventing disk fractures during high-speed operations. Additionally, protective guards and safety glasses are critical components that should be observed. Therefore, purchasing disks with reinforced safety features can reduce risks and ensure a safer working environment for users in industrial or DIY settings.

Application Needs

Emery grinding disks are available in distinct shapes and sizes which suit varied applications. Grinding disks are appropriate for aggressive material removal. At the same time, flap disks are suitable for blend grinding and finishing purposes. In addition, a sanding disc for grinder and polishing wheel are created for fine surface finishing.

When purchasing grinding discs, buyers need to think about key specs and maintenance tips. Here’s a detailed rundown:

Material Composition

Grinding disks are made using different materials. That’s why buyers need to consider the material the disk is made of. Materials include aluminum oxide, zirconia, and silicon carbide. Each of these is meant for different tasks. For instance, silicon carbide is suitable for hard materials like carbide and glass. At the same time, zirconia is suitable for tasks involving stainless steel.

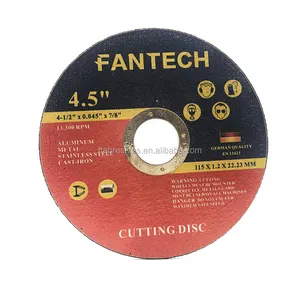

Disk Size and RPM Rating

In this case, the disk size refers to the diameter. It must be compatible with the power tool used. Also, the disk should have an appropriate RPM rating. Thus, it should match the tool’s operating speed to guarantee safety and performance. In industrial settings especially, employees should always replace worn-out disks of varying sizes from reliable suppliers like Alibaba.com. Ensure the disk size and RPM ratings correspond to the tools at hand for safety and effectiveness.

Durability and Grit Size

To ensure long life, opt for durable disks that come with high-quality abrasives. Choose from a selection of disks that contain various grit sizes. Low grit numbers are for heavy grinding. Conversely, high grit numbers are suitable for fine grinding. Also, consider the grit type that has been drawn deep into the bond for exceptional stock removal.

Check the Disk’s Integrity

Disks that are damaged, worn out, or have cracks should be replaced immediately. Also, disks that have bent backgrounds should be replaced too. In this case, users should periodically check the disks’ integrity to avoid compromised performance and safety. To eliminate such disks, users should do a visual inspection before using them.

Storage

Users should store the disks in a cool place until they are required. Also, the storage area should be free from water and other contaminants. The disks should be kept in a protective case to avoid them coming into contact with one another.

Emery sanding disks have innovative uses apart from their principal function. Here’s a list:

Precision Engravings on Metal

Emery grinding disks are ideal for artists and jewelers who want to put fine engravings on metal surfaces. The disk's rough texture offers better control during engraving enabling artists to create intricate designs and detailed patterns. Henceforth, it makes emery disks an asset in metal artistry and jewelry fabrication. They guarantee precision as well as a smooth finish on detailed works.

Sharpening Cutting Tools

Emery disks are effective in sharpening a wide range of cutting tools in workshops and kitchens. Their abrasive surface helps in eradicating material from the edges of blades maintaining a sharp cutting edge over time. Users should use specific grit sizes according to their tasks. Lower grits are appropriate for significant sharpening. On the other hand, higher grits are ideal for honing a fine edge. Further, it provides a dual function of sharpening and polishing which makes them a versatile tool for keeping knives, chisels, and other cutting implements in optimal condition.

Restoring Antique Tools

Restoration enthusiasts employ emery disks to refurbish antique tools used for carving and grinding. The abrasive action of the disk helps in removing rust, corrosion, and accumulated deposits from old metal surfaces. This process rejuvenates the tool's functionality while preserving its historical characteristics. Therefore, these disks are valuable for those engaged in restoration projects.

Engraving on Glass

Emery disks are usually employed by artists for engraving and cutting glass. Due to their fine abrasive particles, they permit detailed etchings on glassware, mirrors, and artistic pieces. This technique produces remarkable designs without damaging the glass. It earns them a place among glass artists and crafters who specialize in customized glass products.

Yes, emery disks are suitable for sanding concrete floors. However, concrete floors require coarse grinding wheels. These disks are manufactured with a rough surface that aids in the removal of material from the floor surface. Moreover, the adhesive is waterproof, so it won’t come off during dry grinding or wet grinding.

Emery disks consist of tightly packed emery (corundum) on a flexible backing material, such as paper, cloth, or fiber. The abrasive material grinded and evenly distributed is mixed with a bonding agent and then applied to the backing. This forms a thick layer of abrasive particles on the surface.

Mild to medium grit normally ranging from 120 to 240 is suitable for natural nails. Grits above 240 are manufactured for nail polish. These offer a smooth finish. Lower grits are usually used for reshaping and removing nail enhancements.

In glass and stone engraving, emery disks are used to create detailed designs and patterns. The fine abrasive particles on the disk allow precise control over the engraving depth and width. This makes them ideal for artists and craftsmen working on intricate engraving projects.

Emery disks are repurposed to create precision tools. For instance, disks with finer grits can be used for precise engraving on metals, glass, and stones. Also, disks with coarse grits can help sharpen blades and cutting tools.